Preparation method of bulky-grain spinel lithium manganate material

A technology of spinel lithium manganese oxide and large particles, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as inappropriate high-temperature calcination process, harmful cycle life due to oxygen deficiency, and unimproved cycle life, etc., to achieve Low cost, complete crystal grains, and excellent high and low temperature cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The raw materials used are industrial-grade manganese dioxide, lithium carbonate and aluminum hydroxide, and the final ratio is Li 1.05 mn 1.77 Al 0.18 Ox, first mix manganese dioxide and aluminum hydroxide evenly according to the ratio, sinter at 1100°C for 10 hours, cool to 200°C, and mix with lithium carbonate after crushing, sinter at 800°C for 10 hours and slowly cool to 200°C, and then crush Milling and grading the powder can obtain the desired spinel lithium manganese oxide.

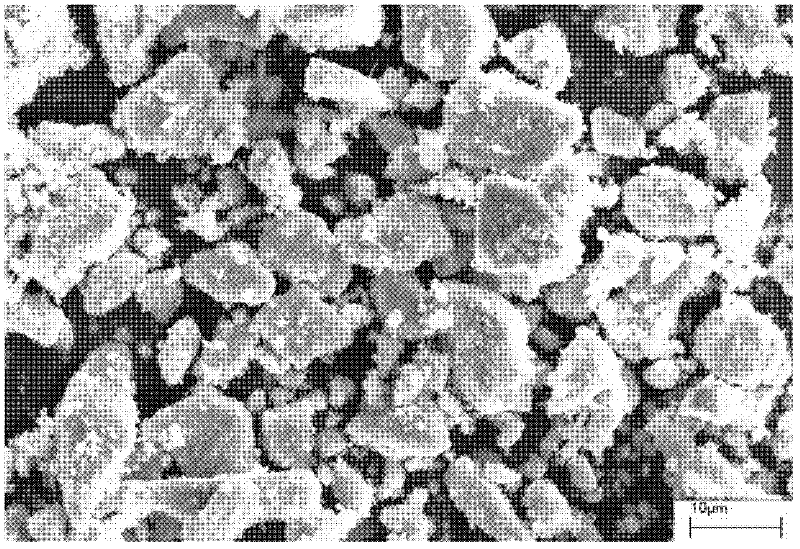

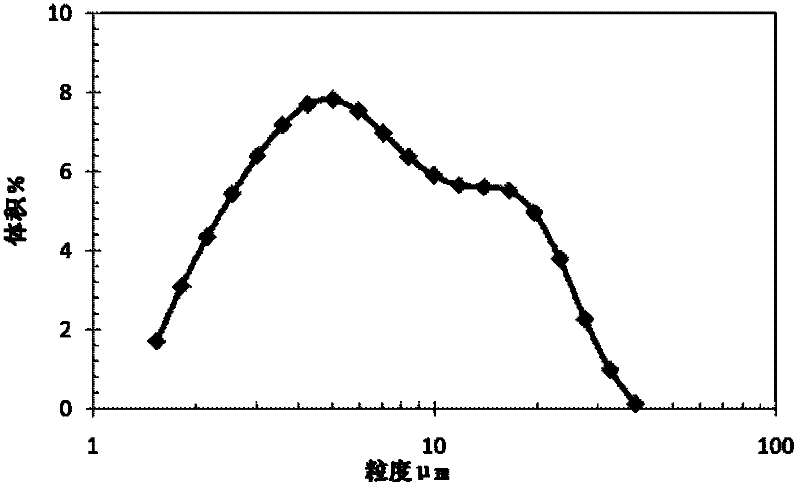

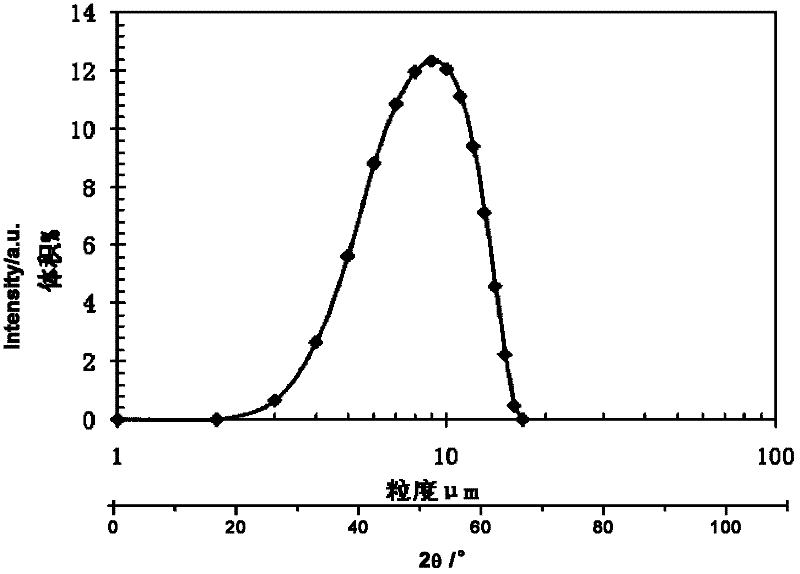

[0030] The raw material manganese dioxide used is flake (such as figure 1 ), wide particle size distribution (such as figure 2 ), the product obtained by sintering in the first stage is tested by XRD, such as image 3 As shown, the product is trimanganese tetraoxide. Figure 4 It can be seen from the SEM image that the grains have a complete crystal shape and a particle size of about 8 microns. Figure 5 Is the particle size distribution, it can be seen that the particle size distri...

Embodiment 2

[0034] The raw materials used are industrial-grade manganese dioxide, lithium carbonate and tricobalt tetroxide, and the final ratio is Li 1.1 mn 1.72 co 0.18 Ox, first mix manganese dioxide and tricobalt tetroxide evenly according to the proportion, sinter at 1100°C for 10 hours, cool in the air, mix with lithium hydroxide after crushing, sinter at 800°C for 10 hours and slowly cool to 200°C, then crush and make powder , powder classification, that is, to obtain the desired spinel lithium manganese oxide.

[0035]

Embodiment 3

[0037] The raw materials used are industrial-grade manganese carbonate, lithium carbonate, aluminum hydroxide and yttrium oxide, and the final ratio is Li 1.1 mn 1.72 Al 0.13 Y 0.05 Ox, first mix manganese tetraoxide, aluminum hydroxide and yttrium oxide evenly according to the proportion, sinter at 1200°C for 10h, and cool in the air after cooling to 1000°C, mix with lithium hydroxide after crushing, and sinter at 800°C After 10 hours of slow cooling to 200°C, it was crushed to make powder, and the powder was classified to obtain the desired spinel lithium manganese oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com