Bulk-phase doped manganous-manganic oxide as well as preparation method and application thereof

A technology of trimanganese tetraoxide and doping, which is applied in the direction of manganese oxide/manganese hydroxide, electrochemical generators, active material electrodes, etc., and can solve the problem of inability to uniformly disperse doping elements, reduce battery product capacity, and high-temperature cycle Poor performance and other problems, to achieve the effect of improving high temperature performance and cycle performance, low production cost, and improving compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

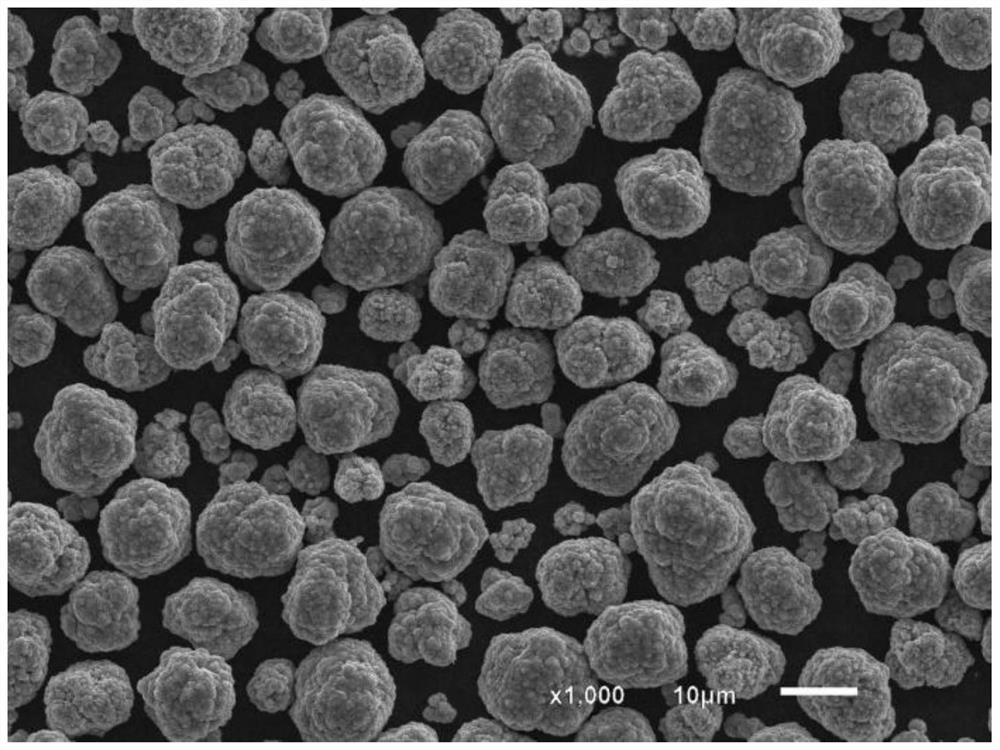

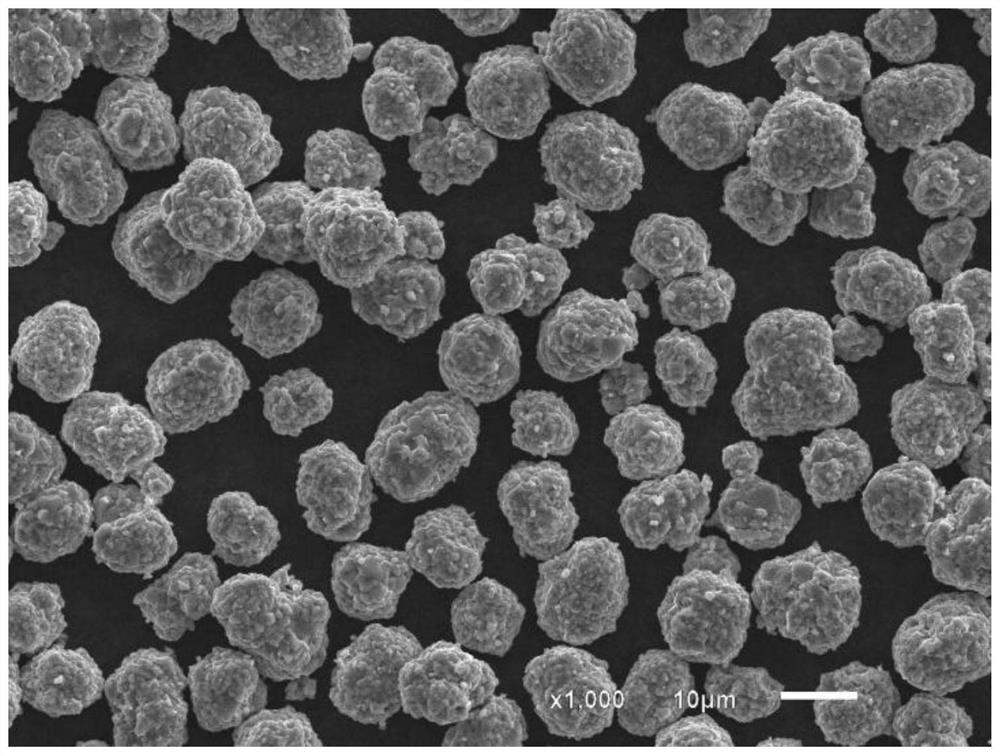

Image

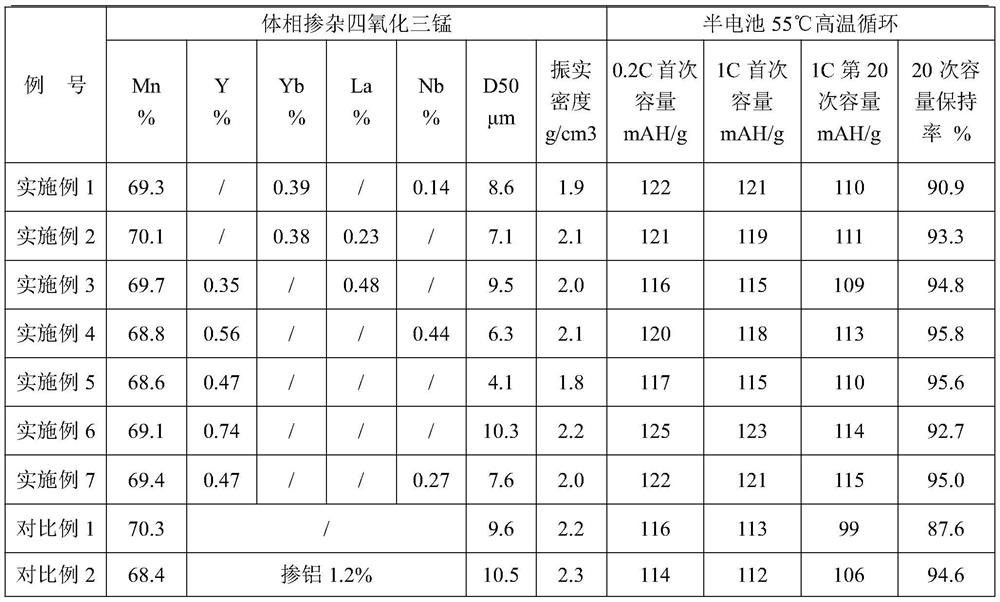

Examples

Embodiment 1

[0033] A bulk phase doped trimanganese tetroxide of the present invention, the bulk phase doped trimanganese tetraoxide is doped with ytterbium and niobium, the content of ytterbium is 0.39%, and the content of niobium is 0.14%; the bulk phase doped Type manganese tetraoxide D50 particle size is 8.6μm, tap density is 1.9g / cm 3 .

[0034] The preparation method of the bulk phase doped trimanganese tetraoxide of the present embodiment comprises the following steps:

[0035] (1) Prepare Mn with manganese sulfate and ytterbium sulfate 2+ The concentration is 80g / L, Yb 3+ Concentration is the mixed solution of 0.55g / L, is the soluble niobium solution of 0.18g / L with niobium pentoxide dissolved with sulfuric acid under the aid of ammonium fluoride to form niobium content;

[0036] (2) preparation concentration is the ammonia solution of 80g / L;

[0037] (3) Add the mixed solution prepared by step (1), soluble niobium solution and the ammonia solution of step (2) continuously with...

Embodiment 2

[0041] A bulk phase doped trimanganese tetroxide of the present invention, the bulk phase doped trimanganese tetraoxide is doped with ytterbium and lanthanum; wherein, the content of ytterbium is 0.38%, and the content of lanthanum is 0.23%, the bulk phase Doped trimanganese tetraoxide D50 particle size is 7.1μm, tap density is 2.1g / cm 3 .

[0042] The preparation method of the bulk phase doped trimanganese tetraoxide of the present embodiment comprises the following steps:

[0043] (1) Prepare Mn with manganese sulfate, ytterbium sulfate and lanthanum sulfate 2+ The concentration is 80g / L, Yb 3+ The concentration is 0.55g / L, La 2+ A mixed solution with a concentration of 0.3g / L;

[0044] (2) preparation concentration is the ammonia solution of 100g / L;

[0045] (3) With a peristaltic pump, the mixed solution prepared in step (1) and the aqueous ammonia solution in step (2) are continuously added to a volume of 20L in a stirred reactor, and the temperature of the control r...

Embodiment 3

[0049] A bulk phase doped trimanganese tetroxide of the present invention, the bulk phase doped trimanganese tetroxide is doped with yttrium and lanthanum; wherein, the content of yttrium is 0.35%, and the content of lanthanum is 0.48%, the bulk phase Doped trimanganese tetraoxide D50 particle size is 9.5μm, tap density is 2.0g / cm 3 .

[0050] The preparation method of the bulk phase doped trimanganese tetraoxide of the present embodiment comprises the following steps:

[0051] (1) Prepare Mn with manganese sulfate, yttrium sulfate and lanthanum sulfate 2+ The concentration is 100g / L, Y 3+ The concentration is 0.7g / L, La 3+ A mixed solution with a concentration of 0.75g / L;

[0052] (2) preparation concentration is the ammonia solution of 150g / L;

[0053] (3) With a peristaltic pump, the mixed solution prepared in step (1) and the aqueous ammonia solution in step (2) are continuously added to a volume of 20L in a stirred reactor, and the temperature of the control reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com