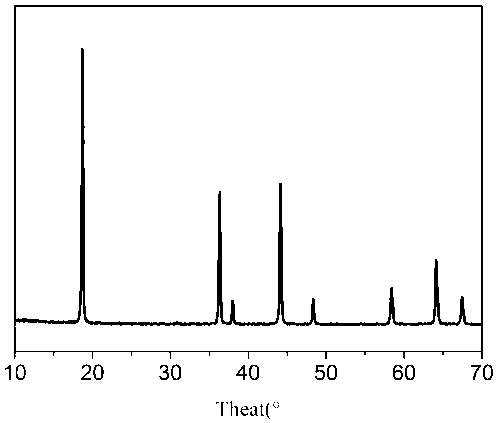

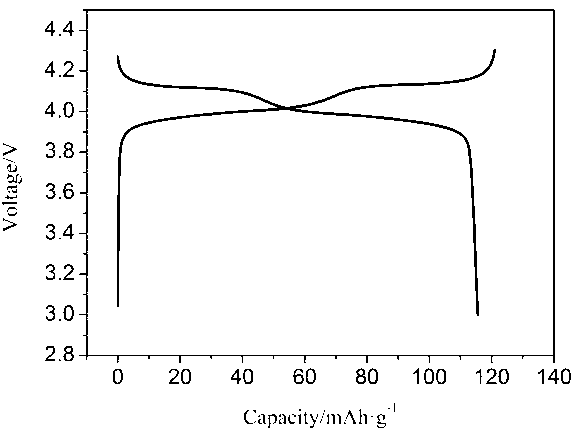

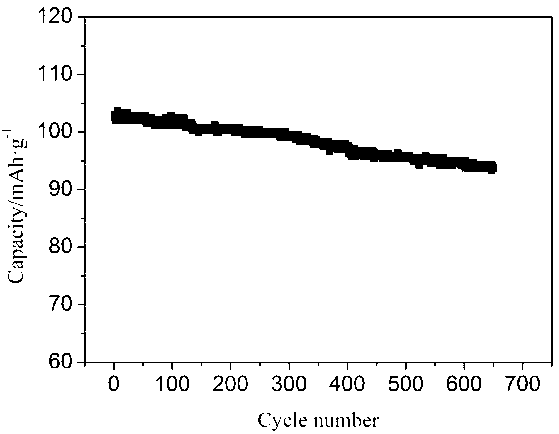

Preparation method of lithium manganese oxide spinel positive material

A positive electrode material, spinel technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of limiting wide application, battery capacity attenuation, poor compatibility, etc., to shorten the reaction time, reduce volatilization loss, The effect of high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 1g of cobalt nitrate and 1.5g of aluminum nitrate in 20ml of water, add 0.5g of zirconia and 1g of lithium fluoride to ultrasonically disperse for 10 minutes, then mix with 100g of electrolytic MnO 2 After mixing, dispersing evenly and drying, heating at 500°C for 5 hours, and cooling to obtain crystal lattice doped with cobalt, aluminum, zirconium and fluorine, and containing MnO 2、 mn 2 o 3 Mixed crystal structure, Mn 3+ , Mn 4+ Coexisting manganese oxide precursors.

[0032] (2) with LiCO 3 The lithium source and the doped manganese oxide precursor obtained in (1) are mixed according to an excess of 3% Li, and 0.5 g of lithium fluoride is added at the same time.

[0033] (3) Mix the raw materials in (2) with ethanol as a dispersant, mix and ball mill for 3 hours according to the ratio of 1:1 ball to material, then dry it, then place it in a high-temperature furnace for calcination at a constant temperature of 600°C for 12 hours, and cool it to room ...

Embodiment 2

[0036] (1) Dissolve 1.2g of magnesium nitrate in 20ml of water, add 0.5g of nano-alumina and 0.5g of lithium fluoride to ultrasonically disperse for 10 minutes, then mix with 100g of electrolytic MnO 2 After mixing, dispersing evenly and drying, heat at 700°C for 2 hours, and after cooling, obtain crystal lattice doped with magnesium, aluminum and fluorine, and containing MnO 2、 mn 2 o 3 Mixed crystal structure, Mn 3+ , Mn 4+ Coexisting manganese oxide precursors.

[0037] (2) Lithium hydroxide is used as the lithium source and the doped manganese oxide precursor obtained in (1) is mixed with an excess of 5% Li, and 1 g of lithium fluoride is added at the same time.

[0038] (3) Mix the raw materials in (2) with ethanol as a dispersant, mix and ball mill for 1 hour according to the ratio of 1:3 ball to material, then dry it, then place it in a high-temperature furnace for calcination at a constant temperature of 700°C for 5 hours, and cool it to room temperature to obtain ...

Embodiment 3

[0041] (1) Add 1g of cobalt oxide, 0.5g of alumina and 1g of lithium fluoride to 20ml of water for ultrasonic dispersion for 20 minutes and mix with 100g of electrolytic MnO 2 After mixing, dispersing evenly and drying, heat at 750°C for 4 hours, and after cooling, a crystal lattice doped with cobalt, aluminum and fluorine, and containing MnO is obtained. 2、 mn 2 o 3 Mixed crystal structure, Mn 3+ , Mn 4+ Coexisting manganese oxide precursors.

[0042] (2) with LiCO 3 The lithium source and the doped manganese oxide precursor obtained in (1) are mixed according to an excess of 4% Li, and 1 g of lithium fluoride is added at the same time.

[0043] (3) Mix the raw materials in (2) with ethanol as a dispersant, mix ball mill at a ratio of 1:1 and ball mill for 5 hours, then dry them in a high-temperature furnace at a constant temperature of 700°C for 12 hours, cool to room temperature, and obtain high-magnification , High cycle performance spinel structure lithium manganate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com