Method for producing high-capacity lithium manganate by using manganous manganic oxide

A technology of trimanganese tetraoxide and lithium manganate, which is applied in the direction of manganate/permanganate, electrical components, battery electrodes, etc., can solve the problem that the capacity of lithium manganate cannot generally adapt to lithium batteries, etc., and achieve a short processing cycle , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

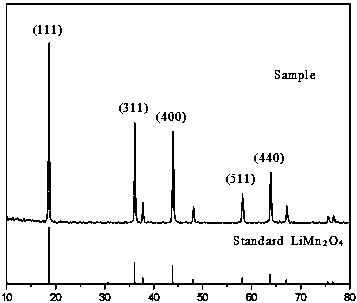

Image

Examples

Embodiment 1

[0036] The method for manganese tetraoxide producing high-capacity lithium manganate comprises the steps:

[0037] a. Raw material mixing: Use 75kg of manganese tetraoxide, and lithium carbonate is mixed according to the molar ratio of lithium to manganese of 0.54, mixed with rare earth element lanthanum with a finished product content of 0.3% as an additive, and mixed evenly by dry method.

[0038] b. Sintering: The uniformly mixed lithium-manganese semi-finished products are sintered in a roller kiln. 6 hours at 650°C, 14 hours at 820°C, 7 hours at 700°C, 7 hours at 700°C, transitional heating and cooling in other temperature zones, the temperature difference of each temperature zone is less than 200°C. During the sintering process of lithium manganate, it is necessary to continuously supplement oxygen and discharge carbon dioxide in time to ensure that the reaction of lithium manganate is sufficient.

[0039] c. Post-sintering treatment: after sintering lithium mangana...

Embodiment 2

[0042] The method for manganese tetraoxide producing high-capacity lithium manganate comprises the steps:

[0043] b. Raw meal mixing: use 75kg of manganese tetraoxide, lithium carbonate is compounded according to the molar ratio of lithium to manganese of 0.53, and cobalt tetraoxide with a finished product content of 0.5% is added as an additive, and mixed evenly by dry method.

[0044] b. Sintering: Sinter the uniformly mixed lithium-manganese semi-finished products in a roller kiln. 550°C heat preservation for 8 hours, 850°C heat preservation for 13 hours, 600°C cooling for 7 hours, transitional heating and cooling in other temperature zones, the temperature difference of each temperature zone is less than 200°C. During the sintering process of lithium manganate, it is necessary to continuously supplement oxygen and discharge carbon dioxide in time to ensure that the reaction of lithium manganate is sufficient.

[0045] c. Post-sintering treatment: After sintering lithiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com