Manganous-manganic oxide preparation method for battery positive pole material lithium manganate and product thereof

A technology of trimanganese tetroxide and lithium manganese oxide, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low tap density, high content of metal impurities, and low median particle size, and achieve compaction density High, good cycle performance, good capacity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

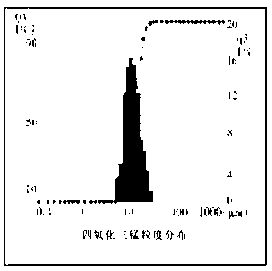

[0016] The preparation method of trimanganese tetraoxide for lithium manganese oxide, the battery cathode material of the present invention, the specific steps are: after the high-purity metal manganese powder is crushed to a certain particle size distribution by dry method, water and ammonium salt are added to the reactor, and then the air is ventilated Oxidation, the air flow rate in the initial stage of the reaction is 20~100 m 3 / h, the air flow is adjusted to 40~300m after the 5th hour of reaction 3 / h, the air flow rate is adjusted to 20~100m after the 12th hour of reaction 3 / h until the end of the reaction, the stirring speed is controlled at 250r / min~450r / min, the time required for the reaction process is 18~28h, and the pH value at the end of the reaction is controlled at 6.4±0.2. After the reaction is complete, it is prepared after washing and drying Trimanganese tetraoxide products.

[0017] Among them, the particle size distribution of manganese metal powder aft...

Embodiment 1

[0021] Dry crush 1000kg of high-purity manganese metal powder to a median particle size of 6μm~8μm, and put it into the reactor that has been added with pure water and 80kg of ammonium salt (a mixture of ammonium chloride and ammonium sulfate), and the stirring speed is controlled at 360r / min . Oxidation by air, the air flow rate in the initial stage of the reaction is 80 m 3 / h, the air flow is adjusted to 200 m after the reaction reaches the fifth hour 3 / h, the air flow rate is adjusted to 40 m after the reaction reaches the 12th hour 3 / h until the end of the reaction. After reacting for 27 hours, the slurry was washed and dried to obtain trimanganese tetraoxide product.

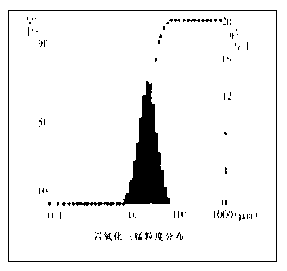

[0022] The trimanganese tetraoxide product obtained in this embodiment: the median particle size is 27 μm, and the specific surface area is 1.65 μm 2 / g, tap density 2.2 g / cm 3 .

Embodiment 2

[0024] Dry crush 500kg of high-purity manganese metal powder to a median particle size of 15μm~20μm, and put it into a reactor that has been added with pure water and 15kg of ammonium chloride, and the stirring speed is controlled at 280r / min. Oxidation by air, the air flow rate in the initial stage of the reaction is 50 m 3 / h, the air flow is adjusted to 150 m after the reaction reaches the fifth hour 3 / h, the air flow rate is adjusted to 50 m after the reaction reaches the 12th hour 3 / h until the end of the reaction. After reacting for about 20 hours, the slurry is washed and dried to obtain trimanganese tetraoxide product.

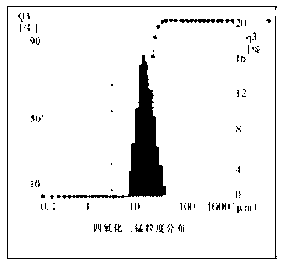

[0025] Manganese manganese tetraoxide product obtained in this embodiment: the median particle size is 18 μm, and the specific surface area is 1.24m 2 / g, tap density 2.8 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com