Preparation method and application of crystalline-state beta-MnOOH nanowire

A nanowire and crystalline technology, which is applied in the field of preparation of β-MnOOH nanowires, can solve the problems of not being very environmentally friendly, and the specific surface area of nanostructures is small, and achieve the effects of low cost, good crystallization performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

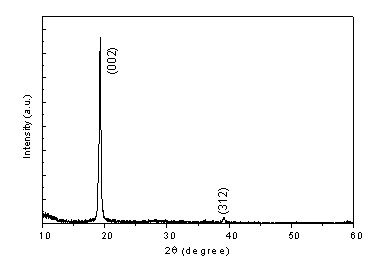

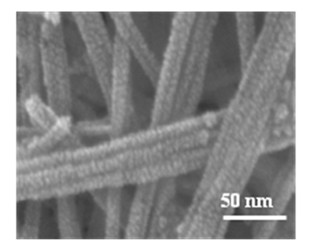

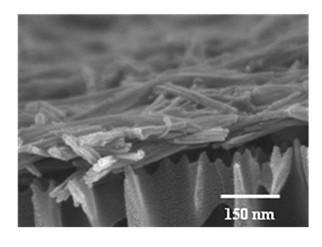

[0028] Preparation and characterization of β-MnOOH nanowires: 10 ml of 0.8 mM ethanolamine (NH 2 CH 2 CH 2 OH) solution was quickly added to 0.4 mM manganous nitrate (Mn(NO) 3 ) aqueous solution, after 1 minute, slow down the stirring speed, and seal the reaction vessel. After one day, brown flocculent precipitate can be obtained, and XRD proves that this precipitate has β-MnOOH crystal structure (see figure 1 ). SEM morphology analysis shows that these precipitates are nanowires with an average diameter of 25 nm and a length of about 1 micron. High-magnification SEM shows that these nanowires are bundled structures formed by parallel arrangement of thinner 3-5 nm nanowires (see figure 1 ). BET tests show that these nanowires have a specific surface area as high as 104 m 2 / g.

Embodiment 2

[0030] Preparation and characterization of β-MnOOH nanowires: Add 10 ml of 0.8 mM NaOH aqueous solution to 0.4 mM manganous nitrate (Mn(NO) 3 ) aqueous solution, after 1 minute, slow down the stirring speed, and seal the reaction vessel. After one day, a brown flocculent precipitate can be obtained, and XRD proves that the precipitate has a β-MnOOH crystal structure. SEM morphology analysis shows that these precipitates are nanowires with an average diameter of 25 nanometers and a length of about 1 micron. High-magnification SEM shows that these nanowires are bundled structures formed by parallel arrangement of thinner nanowires of 3-5 nanometers.

Embodiment 3

[0032] Preparation and characterization of β-MnOOH nanowires: Add 10 ml of 1.0 mM NaOH aqueous solution to 0.6 mM manganous chloride (Mn(NO) 3 ) aqueous solution, after 1 minute, slow down the stirring speed, and seal the reaction vessel. After two days, a brown flocculent precipitate can be obtained, and XRD proves that the precipitate has a β-MnOOH crystal structure. SEM morphology analysis shows that these precipitates are nanowires with an average diameter of 25 nanometers and a length of about 1 micron. High-magnification SEM shows that these nanowires are bundled structures formed by parallel arrangement of thinner nanowires of 3-5 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com