Preparation method for spherical doped lithium manganate

A technology of lithium heteromanganate and spherical shape, which is applied in the field of lithium-ion battery cathode materials, can solve the problems of low impurity content and poor cycle performance of lithium manganate, and achieve the effects of simple process flow, improved cycle performance, and easy realization of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

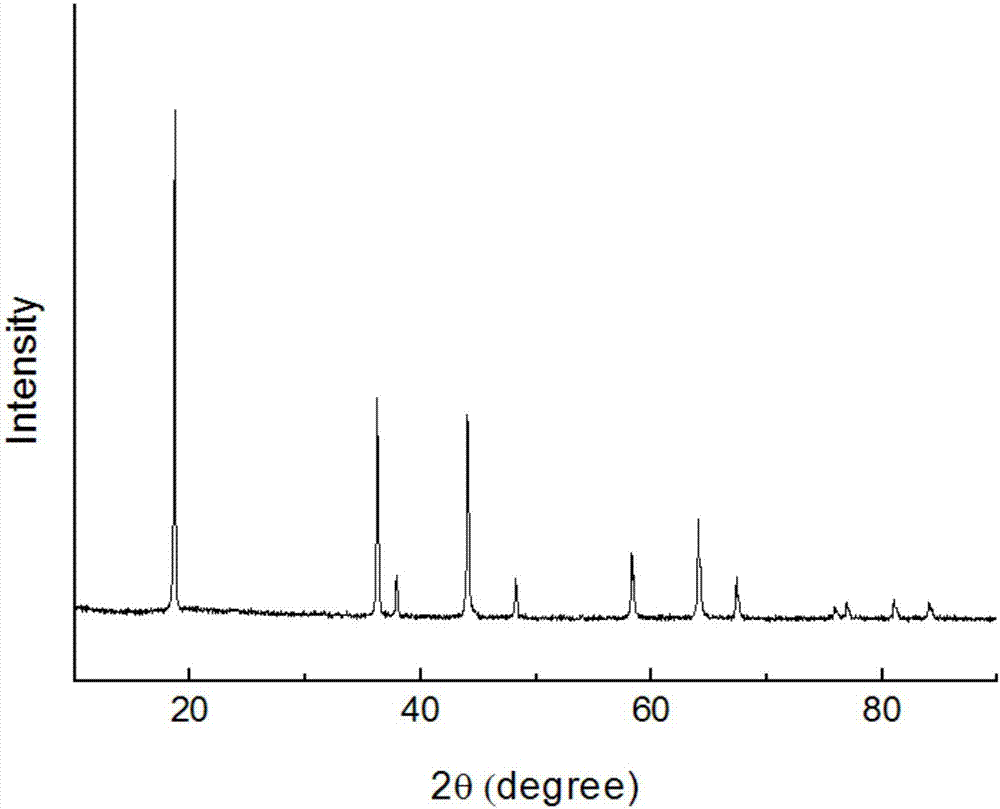

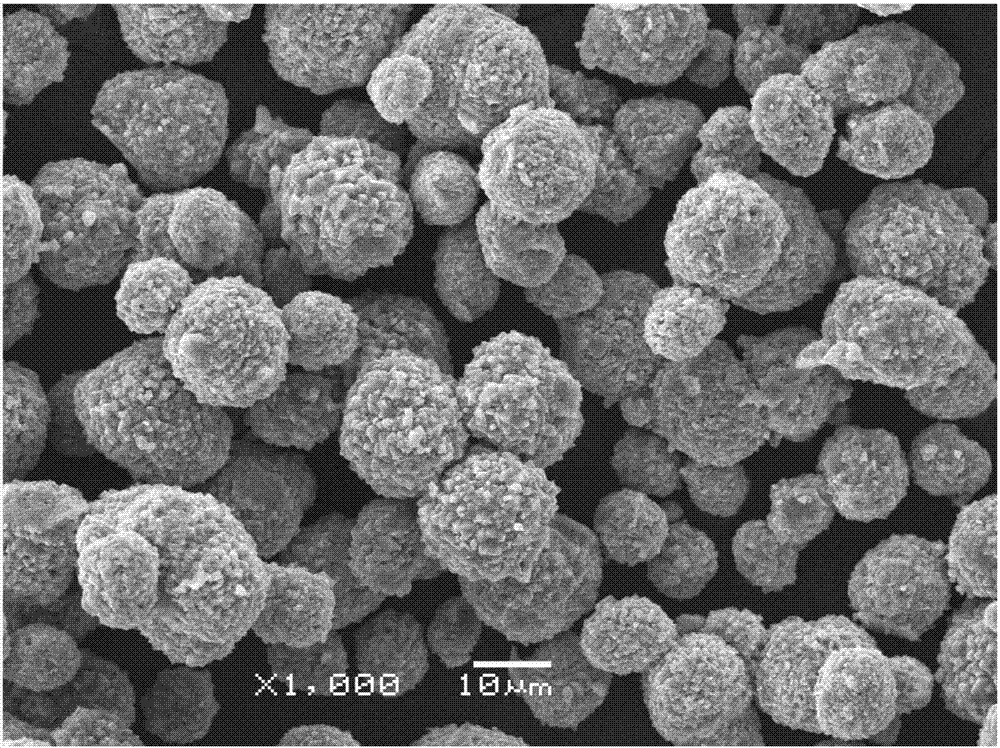

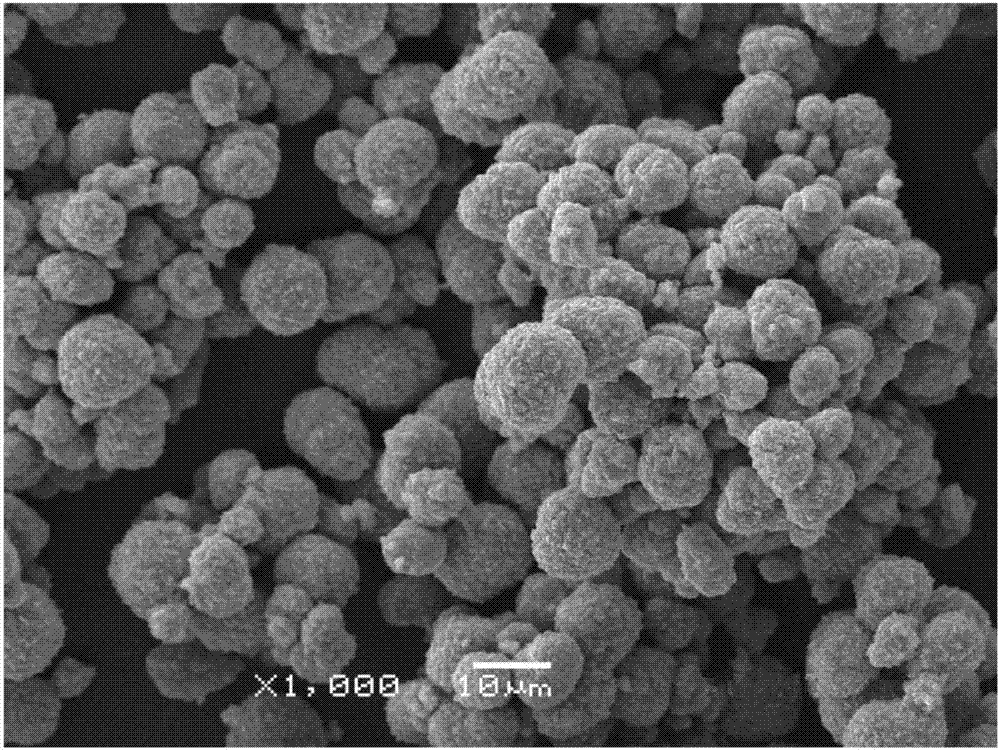

[0025] A kind of preparation method of spherical doped lithium manganate, the chemical formula of spherical doped lithium manganate is Li 1+x mn 2-y m y-x o 4 , wherein M is a doping element, M is at least one of Li, Ni, Mg, Al, Co, Cr, Ti and other elements, 0≤x≤0.1, 0≤y-x≤0.5. Spherical doped lithium manganate is a lithium manganate particle with a cubic spinel structure and space group Fd-3m (No.227); its impurity content is low, and the impurity content of potassium, sodium, and calcium is less than 50ppm, and the impurities of iron and copper are less than 50ppm. The content is less than 20ppm, and the sulfate content is less than 0.1%; the doping elements are uniformly distributed at the molecular level inside the lithium manganate particles, which can improve the structural stability; the microscopic secondary particle morphology is spherical, and the particle size is D 50 5μm~20μm; specific surface area is less than 0.8m 2 / g, the tap density is greater than 2.0g / c...

Embodiment 1

[0038] A kind of spherical doped lithium manganate of the present invention, its chemical formula is Li 1.05 mn 1.80 Al 0.15 o 4 .

[0039] Prepare 20L of mixed solution of manganese sulfate and aluminum sulfate with a divalent manganese ion concentration of 60g / L and a trivalent aluminum ion concentration of 2.5g / L with pure water, weigh 60g of isopropanol and 70g of sodium fluoride and add them to the solution Stir evenly; use pure water to prepare 20L of sodium hydroxide solution with a concentration of 200g / L, according to the flow rate of 500mL / h of manganese sulfate and aluminum sulfate mixed solution, the sum of the moles of manganese ions and aluminum ions and the moles of sodium hydroxide The ratio is 1:2. Use a metering pump to add the mixed solution and sodium hydroxide solution into a reactor with a volume of 10L. The temperature of the reaction is controlled at 70°C, and the pH of the reaction solution is 10.0. At the same time, a sufficient amount of The air ...

Embodiment 2

[0044] A kind of spherical doped lithium manganate of the present invention, its chemical formula is Li 1.05 mn 1.85 Al 0.10 o 4 .

[0045] Prepare 20L of mixed solution of manganese sulfate and aluminum sulfate with a divalent manganese ion concentration of 60g / L and a trivalent aluminum ion concentration of 1.6g / L with pure water, weigh 60g of isopropanol and 70g of sodium fluoride and add them to the above solution and Stir evenly; use pure water to prepare 20L of sodium hydroxide solution with a concentration of 200g / L, according to the flow rate of 500mL / h of manganese sulfate and aluminum sulfate mixed solution, the sum of the moles of manganese ions and aluminum ions and the moles of sodium hydroxide The ratio is 1:2, the mixed solution and sodium hydroxide solution are added into a reactor with a volume of 10L by a metering pump, the pH value of the reaction solution is 10.0, and the temperature of the reaction is controlled to be 70°C. Use 10% hydrogen peroxide to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com