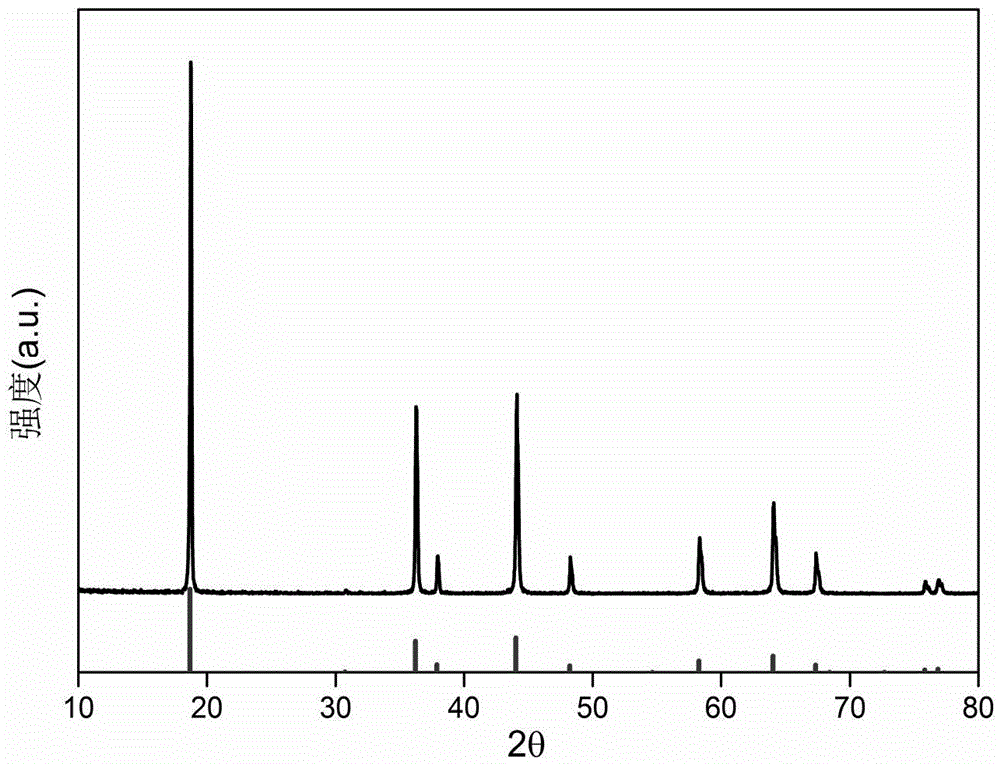

Method for doping and cladding double modifying for lithium manganate in one step

A double-modified, lithium manganate technology, applied in electrode manufacturing, electrode heat treatment, electrical components, etc., can solve the problems of heavy workload and poor product performance improvement effect, achieve cost savings, easy industrial application, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

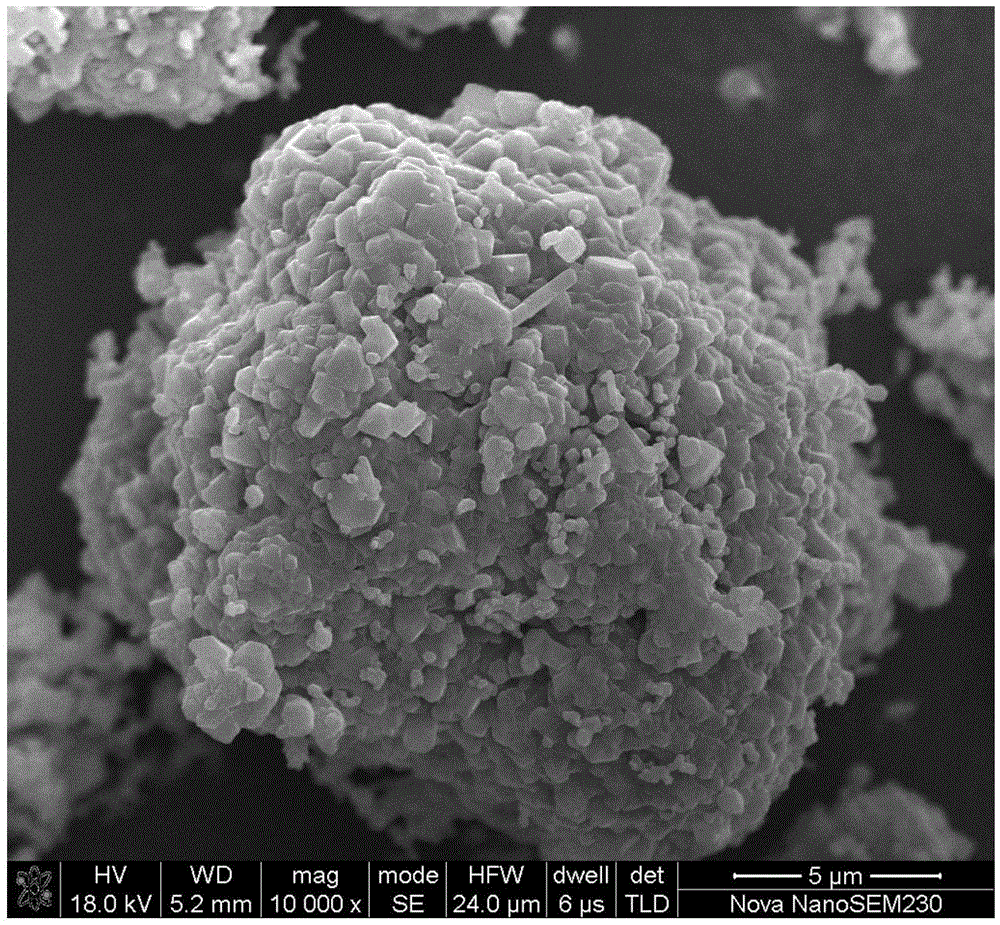

[0037] Weigh 20g trimanganese tetroxide with a median diameter of 12μm and add it to distilled water, and stir in a water bath at 80°C;

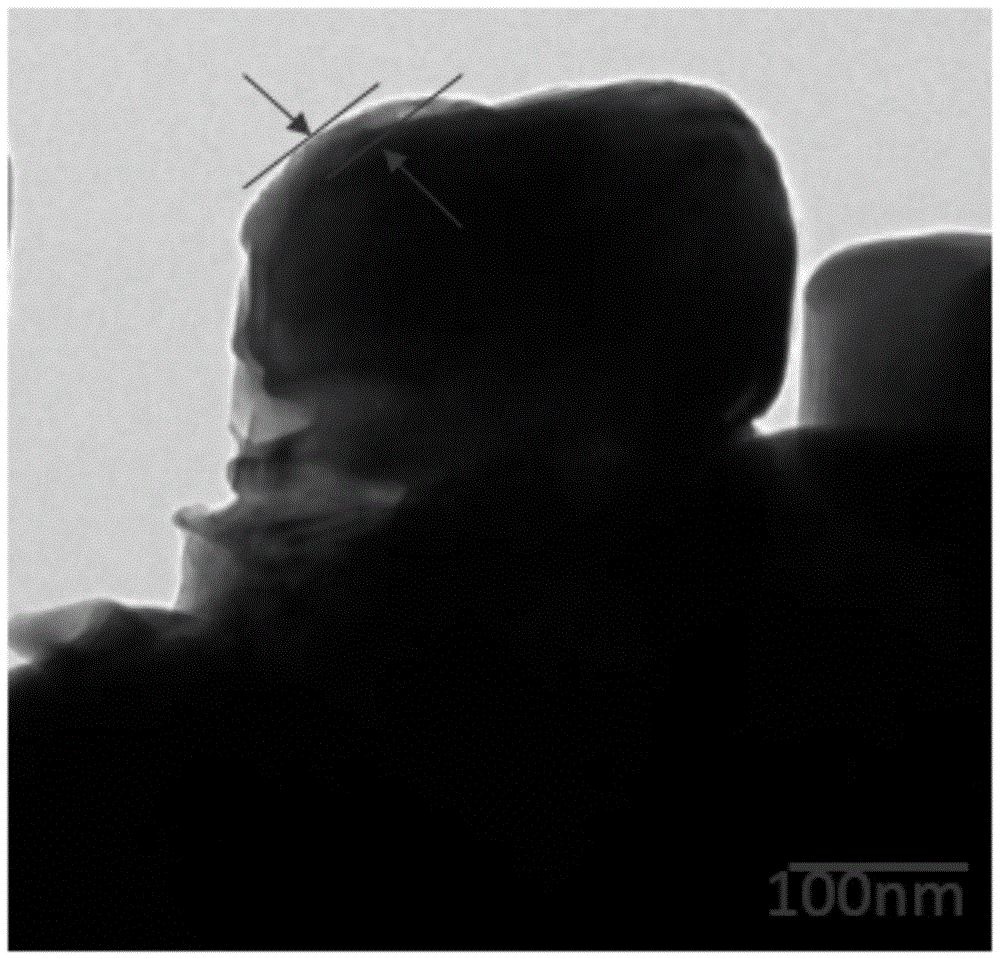

[0038] Dilute 3g of aluminum sol with 20ml of distilled water and slowly drop it into the manganese tetroxide aqueous solution that is rapidly stirred at a speed of 600 rpm / min, continue to stir for 60 minutes, and then place it in an oven at 150°C for 12 hours to dry to obtain a powder;

[0039] The obtained powder and 5.15 g of lithium carbonate are fully ground, and the temperature is raised to 650° C. for 6 hours at a heating rate of 2° C. / min, and the temperature is continued to be increased to 800° C. for 15 hours, and the temperature is naturally cooled to room temperature.

[0040] The trimanganese tetroxide used in all the examples and comparative examples was prepared by the following method:

[0041] Take deionized water and add it to the reaction kettle as the bottom liquid, turn on the heating device and stir at a speed of 500r / min. When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com