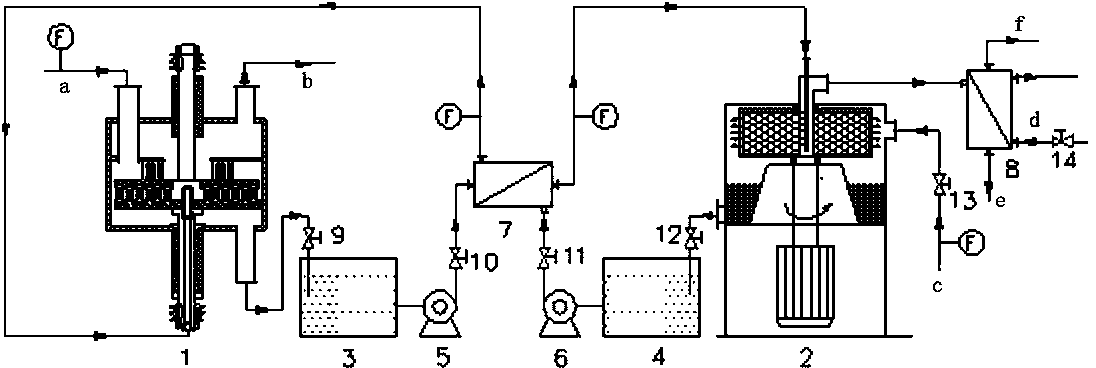

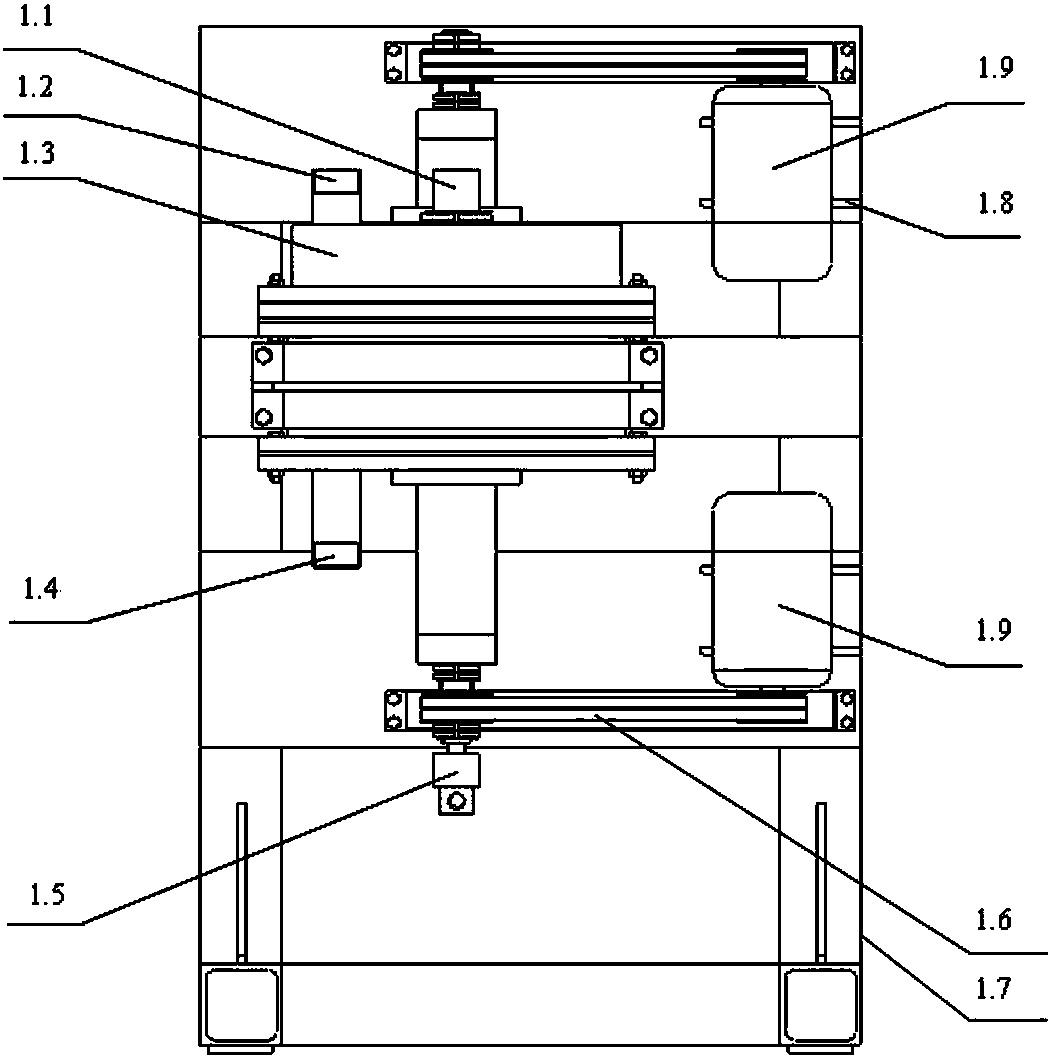

Flue gas desulfurization device and process

A desulfurization device and flue gas technology, applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., to achieve the effects of stable operation, low energy consumption, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

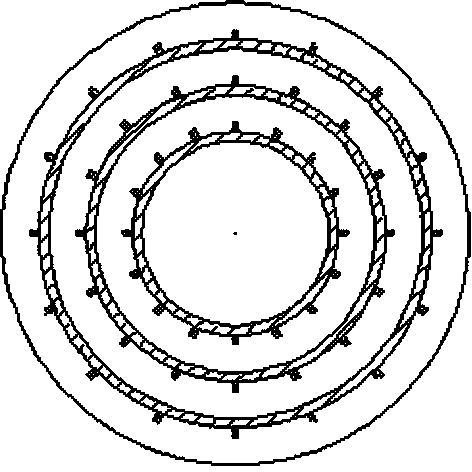

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Set the upper and lower turntables of the rotary packed bed absorber 1 to rotate in reverse, the speed is 400 r / min, the concentration of sodium hydrogen phosphate buffered aqueous solution is 1 mol / L (expressed as phosphate radical), and the pH is 6.5. SO in flue gas 2 The concentration is 0.2%, the flue gas flow rate is 150m3 / h, the liquid-gas ratio is 0.8 L / m 3 , the absorption reaction temperature is 35°C, and the flue gas desulfurization rate is higher than 99.1%. The absorbed rich liquid is desorbed by the rotary packed bed desorber 2, the speed of the desorber is 600 r / min, the temperature of the water vapor is 112°C, the temperature of the desorption operation is 97°C, and the gas-liquid ratio is 600m 3 / m 3 , the desorption rate of the rich solution is higher than 92%.

Embodiment 2

[0057] Example 2: Set the upper and lower turntables of the rotary packed bed absorber 1 to rotate in reverse, the rotation speed is 600 r / min, the concentration of the sodium phosphate buffer solution is 0.5 mol / L (expressed as phosphate radical), the pH is 5.6, and the smoke SO in air 2 The concentration is 0.06%, and the flue gas flow rate is 120 m 3 / h, the liquid-gas ratio is 0.6 L / m 3 , the absorption reaction temperature is 35°C, and the flue gas desulfurization rate is higher than 99.3%. The absorbed rich liquid is desorbed by the rotary packed bed desorber 2, the speed of the desorber is 550 r / min, the temperature of the water vapor is 109°C, the temperature of the desorption operation is 98°C, and the gas-liquid ratio is 500m 3 / m 3 , the desorption rate of the rich solution is higher than 93%.

Embodiment 3

[0058] Example 3: Set the upper and lower turntables of the rotary packed bed absorber 1 to rotate in reverse, the rotation speed is 600 r / min, the concentration of the sodium phosphate buffer solution is 1.5 mol / L (expressed as phosphate radical), the pH is 6.0, and the smoke SO in air 2 The concentration is 1%, and the flue gas flow rate is 150 m 3 / h, the liquid-gas ratio is 3 L / m 3 , the absorption reaction temperature is 40°C, and the flue gas desulfurization rate is higher than 99.4%. The absorbed rich liquid is desorbed by the rotary packed bed desorber 2, the speed of the desorber is 800 r / min, the temperature of the water vapor is 115°C, the temperature of the desorption operation is 97°C, and the gas-liquid ratio is 600 m 3 / m 3 , the desorption rate of the rich solution is higher than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com