a discharge device

A discharge device and a discharge port technology, applied in the direction of packaging, etc., can solve problems affecting filling production, difficulty in discharging viscous liquid materials, etc., achieve convenient cleaning and maintenance, avoid sticking and drawing, and improve cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

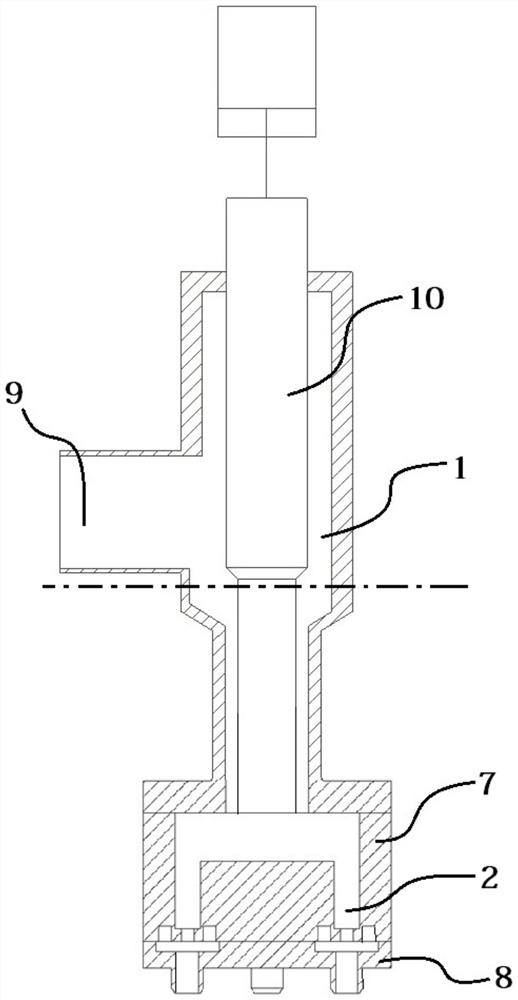

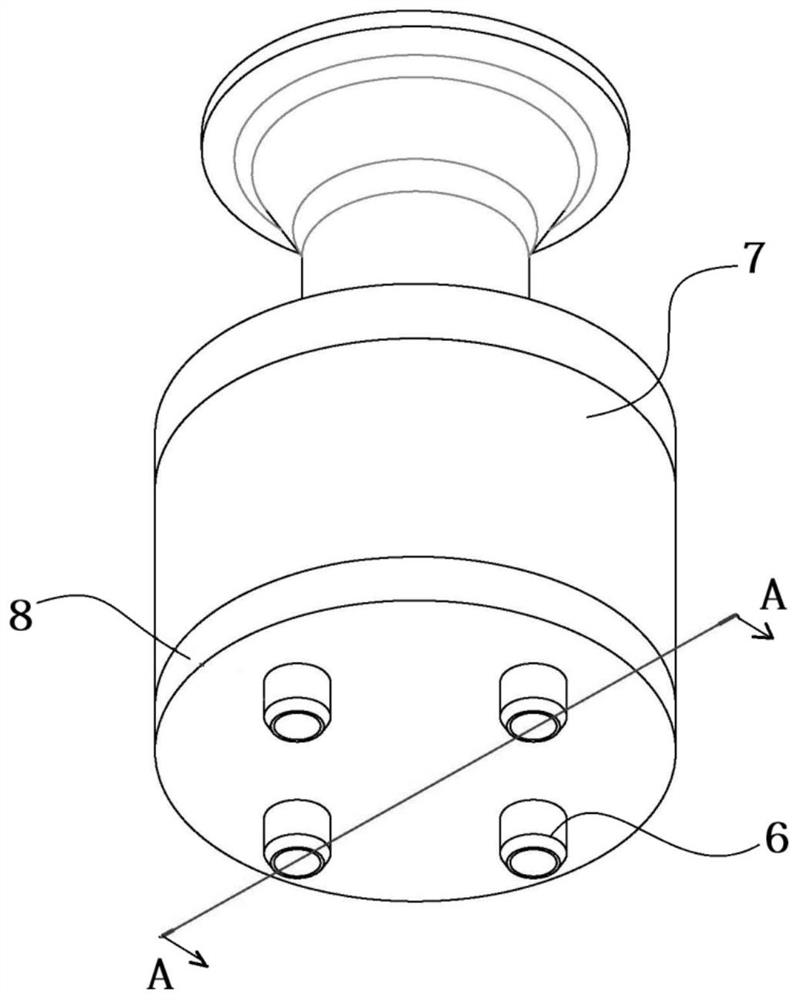

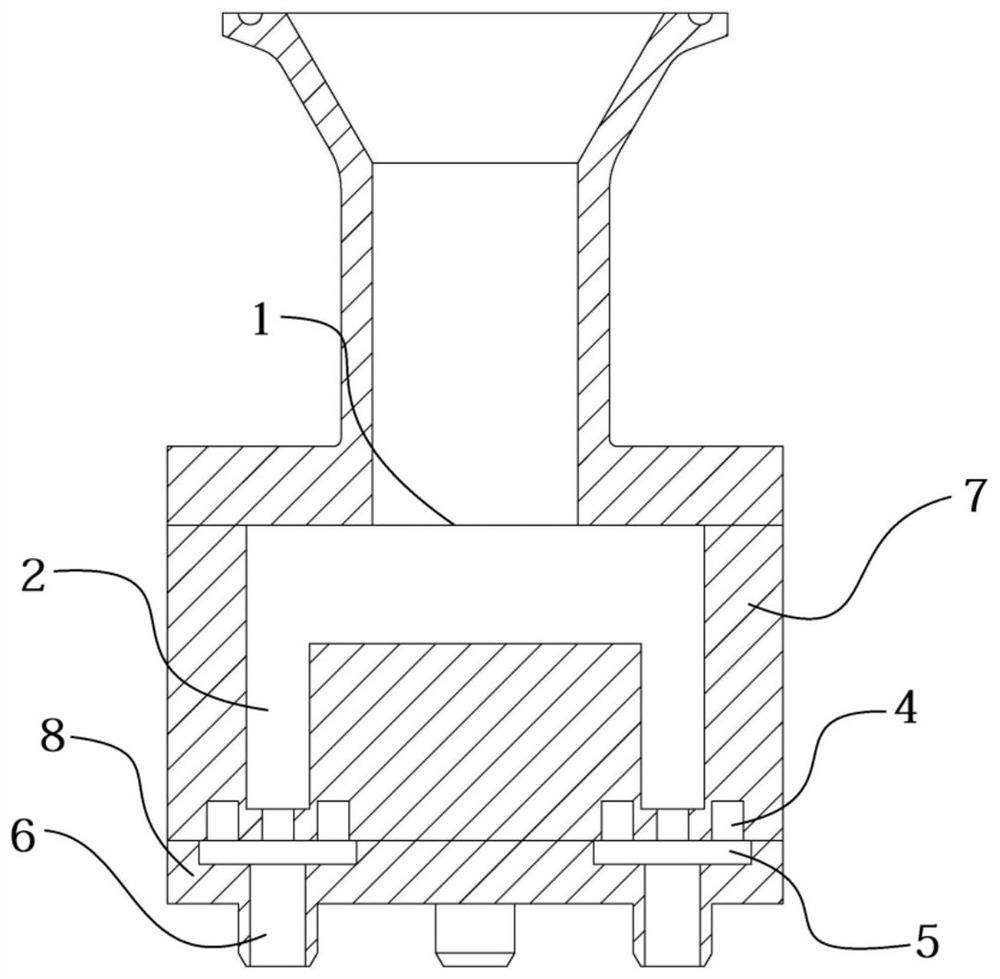

[0039] Such as Figure 1-8 As shown, the discharge device provided in this embodiment includes a feed liquid channel 1, a control valve 10 and a material breaking mechanism, the feed liquid channel has an inflow port 9 and an outflow port, and the control valve 10 can control the on-off of the feed liquid channel 1, The cutting mechanism has a high-pressure fluid channel, which is located at the downstream of the control valve 10 and is arranged near the outlet, and the high-pressure fluid channel is connected with the feed liquid channel 1. When the control valve 10 is in the state of closing the feed liquid channel 1, the high-pressure fluid channel The jetted high-pressure fluid can form a high-pressure cutting surface, quickly cut off the sticky liquid column at the outlet, make it completely cut off, and avoid sticking and drawing. In the production process of the product, it can not only precisely control the filling weight of the product , to control the shape of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com