Preparation method of high-performance alkene-magnesium alloy

A high-performance technology for ene-magnesium alloys, applied in the field of preparation of high-performance ene-magnesium alloys, can solve the problems of low room temperature plasticity, low absolute strength, low dispersion, etc., to reduce impurity content, remove residual stress, and achieve tight bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of modified graphene powder: Dissolve zirconium powder in a hydrofluoric acid solution with a concentration of 40%, then add graphene powder and mix evenly to obtain a mixed slurry, and pass into the mixed slurry with a concentration of 20% N 2 , sonicated for 30 minutes, filtered and dried to obtain modified graphite powder; wherein, the power of the ultrasonic wave was 1.2kW, and the ratio of zirconium powder, graphene powder, and hydrofluoric acid solution was 0.5:1:60 (g:g:ml) .

[0022] Preparation of high-performance ene-magnesium alloys:

[0023] (1) Organic silicon surfactant is mixed with deionized water to make a solution, then added modified graphene powder and mixed evenly, after standing for 10h, placed in a freeze dryer to dry, to obtain mixed graphene powder, for subsequent use; wherein , the ratio of organic surfactant, deionized water, and modified graphene powder is 1:50:1 (g:ml:g);

[0024] (2) Melting magnesium powder and alloying eleme...

Embodiment 2

[0030] Preparation of modified graphene powder: Dissolve zirconium powder in a hydrofluoric acid solution with a concentration of 40%, then add graphene powder and mix evenly to obtain a mixed slurry, and pass into the mixed slurry with a concentration of 25% N 2 , ultrasonically treated for 34in, filtered and dried to obtain modified graphite powder; wherein, the power of ultrasonic wave is 1.0kW, and the ratio of zirconium powder, graphene powder and hydrofluoric acid solution is: 0.8:1:65 (g:g:ml ).

[0031] Preparation of high-performance ene-magnesium alloys:

[0032] (1) Mix the organic silicon surfactant and deionized water to make a solution, then add the modified graphene powder and mix evenly, after standing for 12 hours, place it in a freeze dryer to dry to obtain the mixed graphene powder, which is for subsequent use; The ratio of silicone surfactant, deionized water, and modified graphene powder is 1.2:56:1 (g:ml:g).

[0033] (2) Melting magnesium powder and all...

Embodiment 3

[0039] The preparation of the modified graphene powder is as follows: the zirconium powder is dissolved in a hydrofluoric acid solution with a concentration of 40%, then the graphene powder is added and mixed evenly to obtain a mixed slurry, and the mixed slurry is fed with a concentration of 30% N 2 , sonicated for 40 minutes, filtered and dried to obtain modified graphite powder; wherein, the power of the ultrasonic wave was 0.8kW, and the ratio of zirconium powder, graphene powder, and hydrofluoric acid solution was: 1:1:70 (g:g:ml ).

[0040] Preparation of high-performance ene-magnesium alloys:

[0041] (1) Organic silicon surfactant is mixed with deionized water to make a solution, then added modified graphene powder and mixed evenly, after standing for 15h, placed in a freeze dryer to dry, to obtain mixed graphene powder, for subsequent use; wherein The ratio of silicone surfactant, deionized water, and modified graphene powder is 2:60:1 (g:ml:g).

[0042] (2) Smeltin...

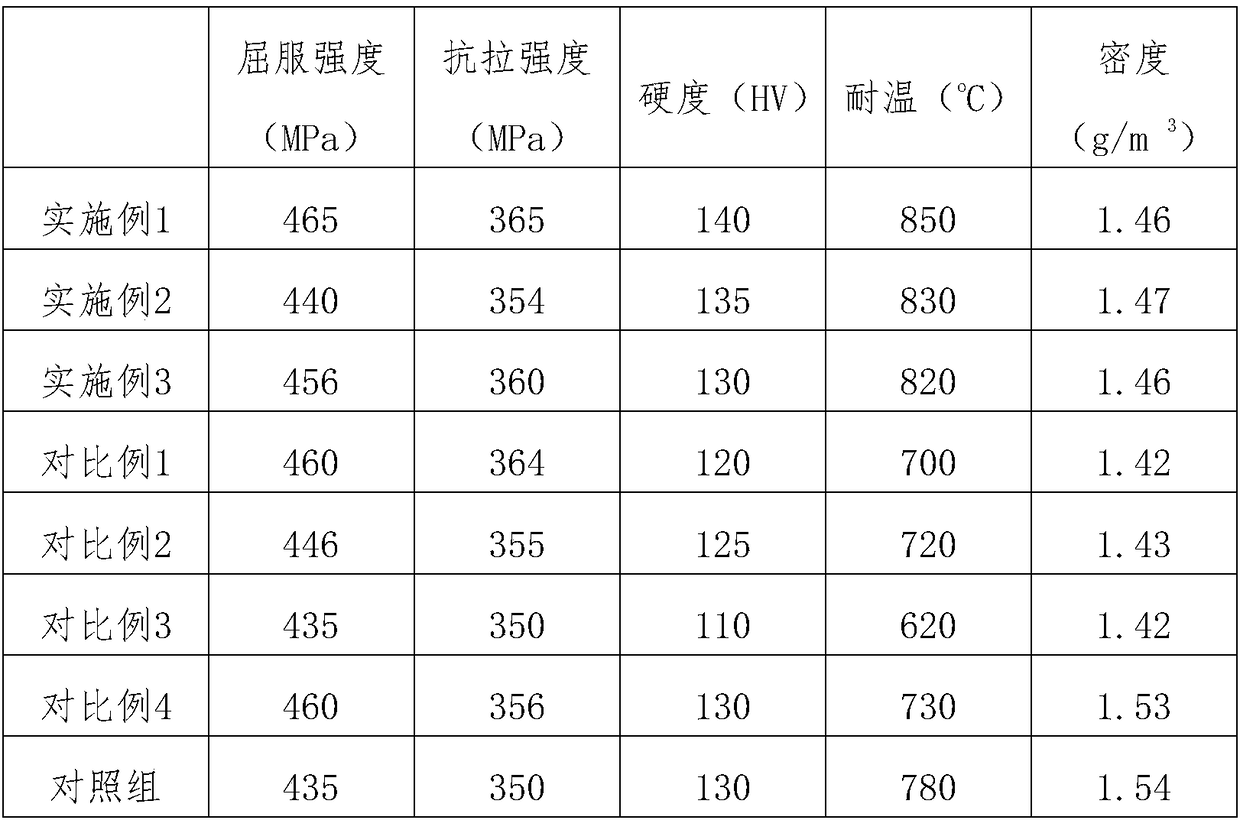

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com