Super-centrifugal and swirl high viscosity spinning method and device for producing nano-fibers

A nanofiber, ultracentrifugation technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of low nanofiber content, uneven fiber diameter, and reduced production rate, and achieve uniform diameter, improve Plasticizing effect, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

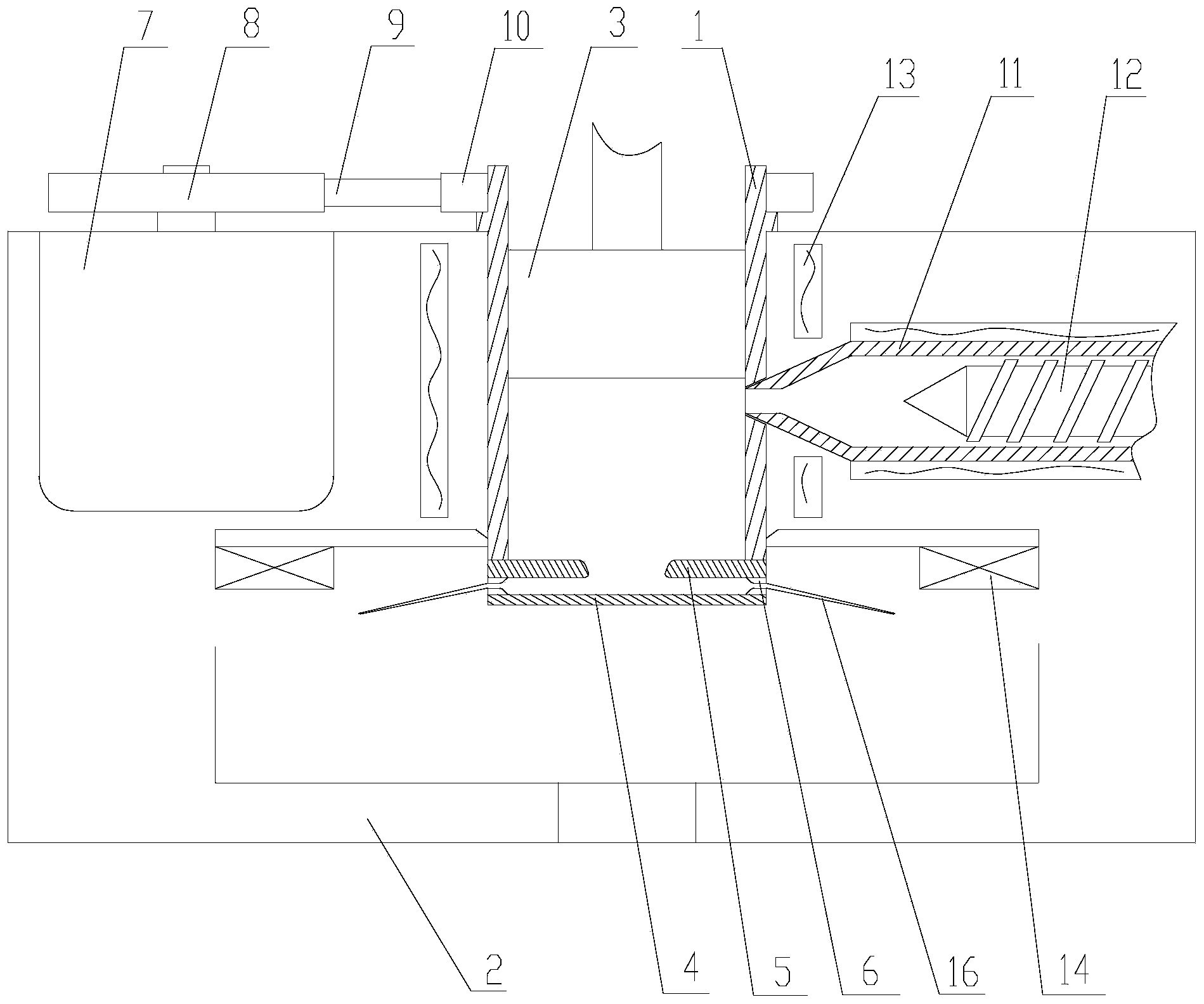

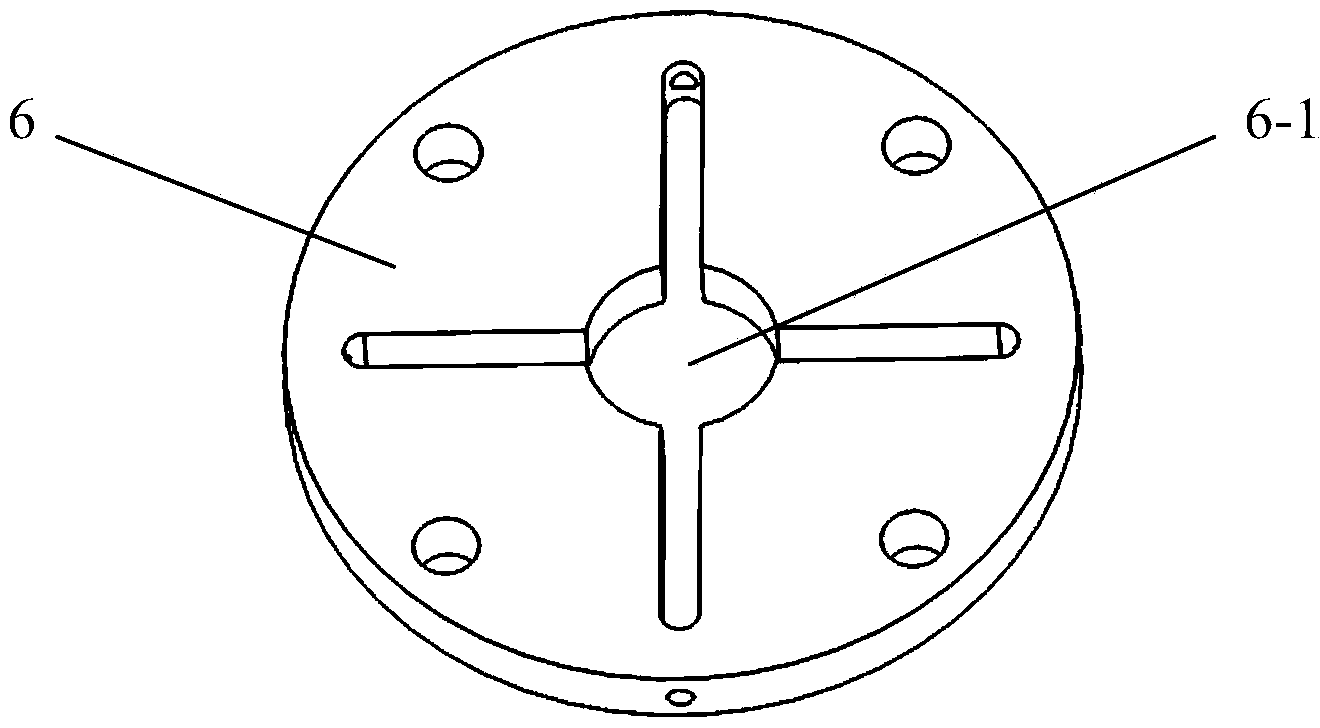

[0030] In this embodiment, a device for preparing nanofibers by ultracentrifugal-swirl high-viscosity spinning is used for melt spinning, and its structure is as follows: figure 1 As shown, it includes a storage tank 1, a fiber receiver 2, a rotary drive mechanism and a feeding mechanism. The fiber receiver is arranged under the storage cylinder, the rotation drive mechanism is arranged on the outer periphery of the storage cylinder, and the feeding mechanism is arranged outside the storage cylinder. There is a feed port on the side wall of the storage tank, which is connected with the feeding mechanism; a plunger rod 3 is arranged in the storage tank, and the plunger rod moves up and down along the inner wall of the storage tank; the bottom of the storage tank A baffle plate 4 is provided, a feed plate 5 is arranged above the baffle plate, and a nozzle plate 6 is arranged between the feed plate and the baffle plate, and the injection port on the nozzle plate is located in the ...

Embodiment 2

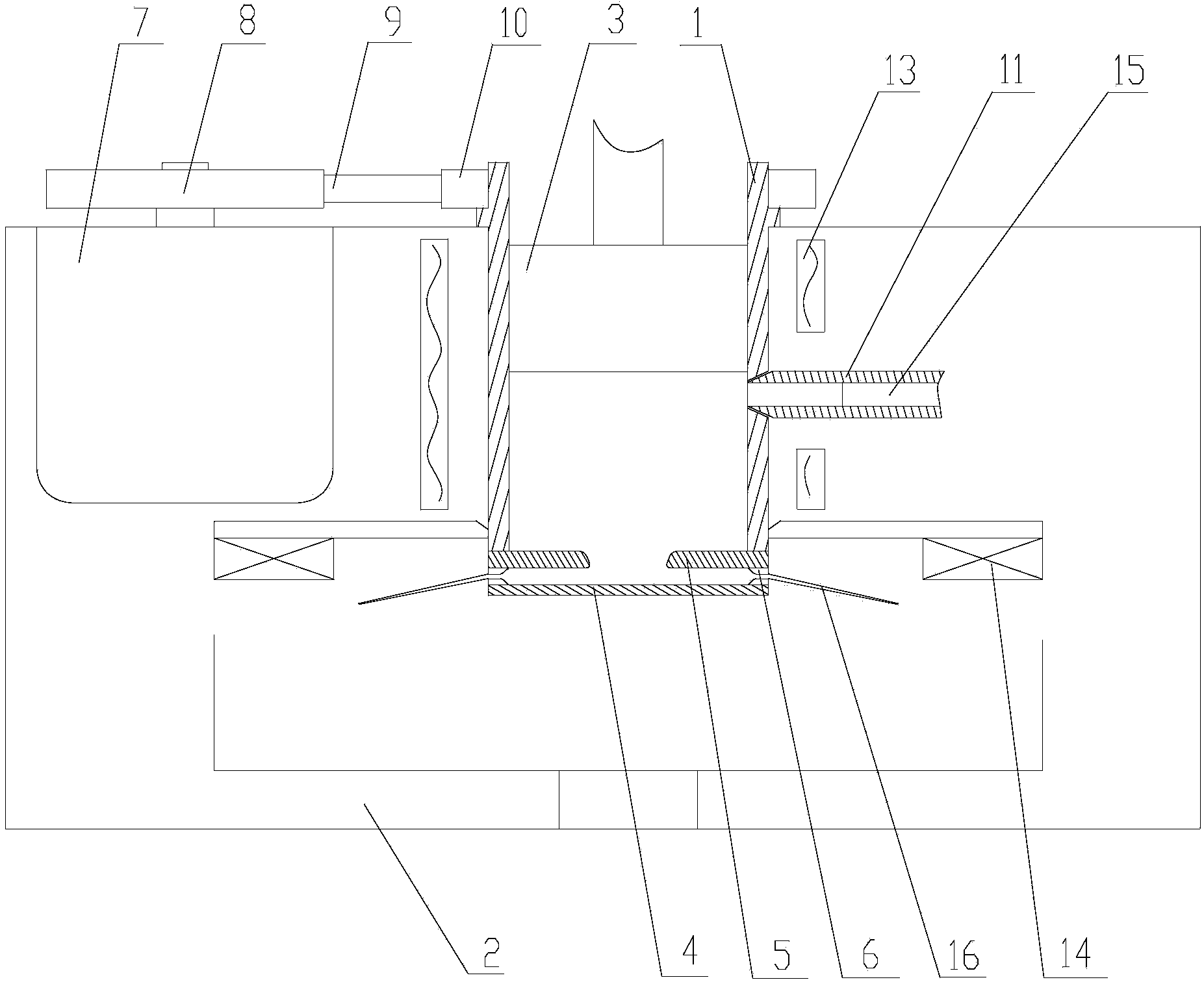

[0041] In this embodiment, a device for preparing nanofibers by ultracentrifugal-swirl high-viscosity spinning is used for solution spinning, and its structure is as follows: figure 2 As shown, it includes a storage tank 1, a fiber receiver 2, a rotary drive mechanism and a feeding mechanism. The fiber receiver is arranged under the storage cylinder, the rotation drive mechanism is arranged on the outer periphery of the storage cylinder, and the feeding mechanism is arranged outside the storage cylinder. There is a feed port on the side wall of the storage tank, which is connected with the feeding mechanism; a plunger rod 3 is arranged in the storage tank, and the plunger rod moves up and down along the inner wall of the storage tank; the bottom of the storage tank A baffle plate 4 is provided, a feed plate 5 is arranged above the baffle plate, and a nozzle plate 6 is arranged between the feed plate and the baffle plate, and the injection port on the nozzle plate is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com