Electrical junction box

A technology for electrical connection boxes and boxes, which is applied in the direction of electrical components, circuits or fluid pipelines, transportation and packaging, etc. It can solve the problems of being introduced into the inside of the cover, easy to stay in the flange part, and unable to promote drainage, so as to improve drainage sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

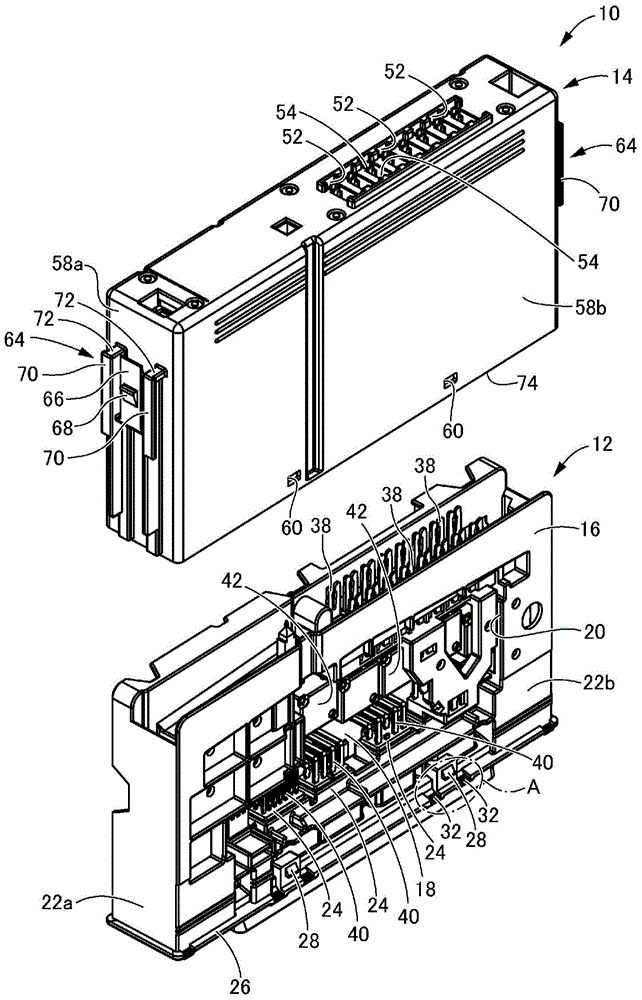

[0032] first, figure 1 The electrical junction box 10 which is one embodiment of this invention is shown. The electrical connection box 10 includes a main body 12 and a cover 14 , and the box-shaped cover 14 opened downward is inserted and attached to the main body 12 from above, whereby the main body 12 is housed and assembled in the cover 14 . The electrical connection box 10 is housed in another electrical connection box such as a relay box, for example, and is mounted on vehicles such as automobiles.

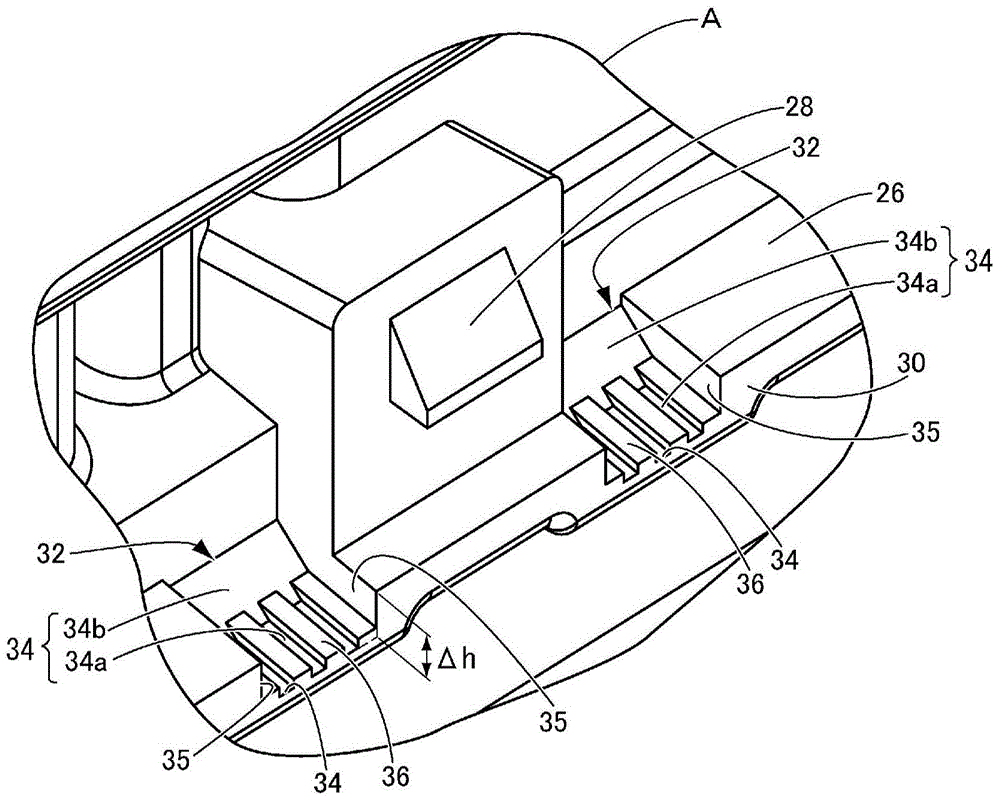

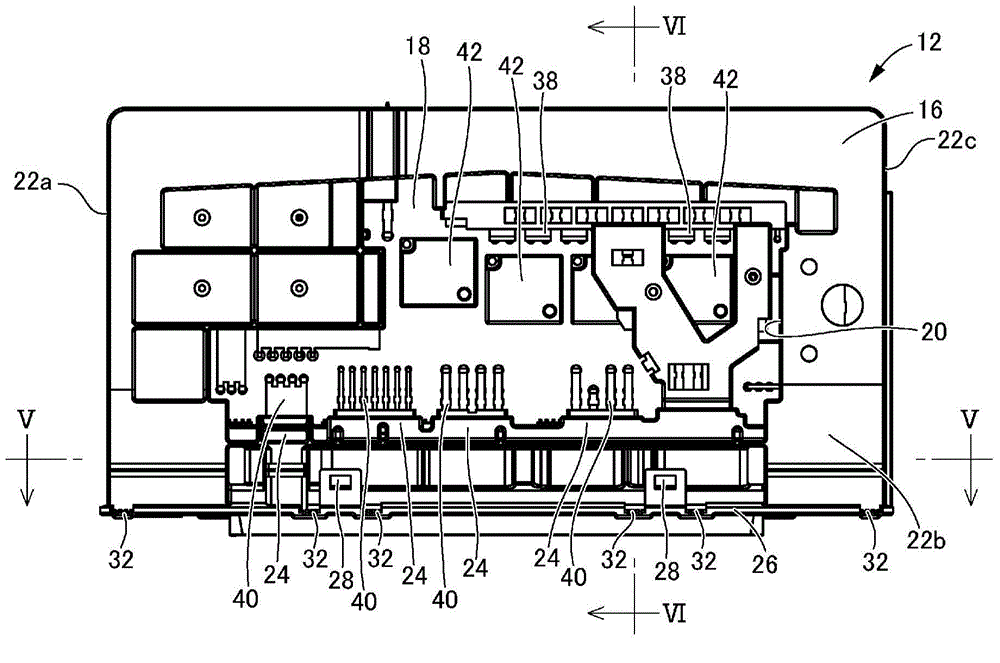

[0033] Figure 2 ~ Figure 6 The main body portion 12 is shown. The main body portion 12 has a vertically long rectangular block shape as a whole. The main body 12 has a structure in which a printed circuit board 18 as an internal circuit is assembled in a housing 16 made of synthetic resin. In addition, the internal circuit is not limited to the printed circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com