Tip-induced electrostatic spinning nozzle and tip-induced electrostatic spinning device

An electrostatic spinning and nozzle technology, which is applied in the directions of spinneret assembly, stretch spinning, textiles and papermaking, etc., can solve the problems of complicated spinning, difficulty in ensuring spinning quality, and complicated spinning device mechanism. The effect of good spinning effect, improving efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

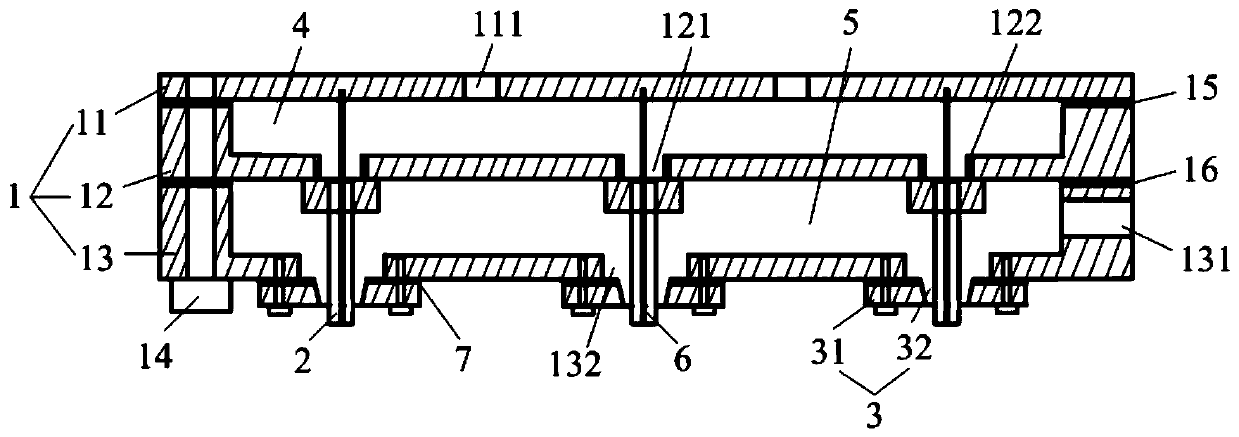

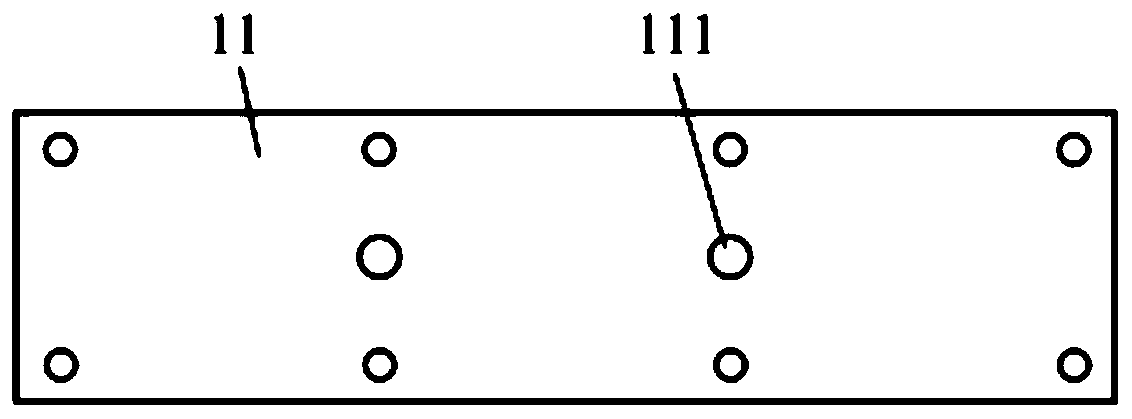

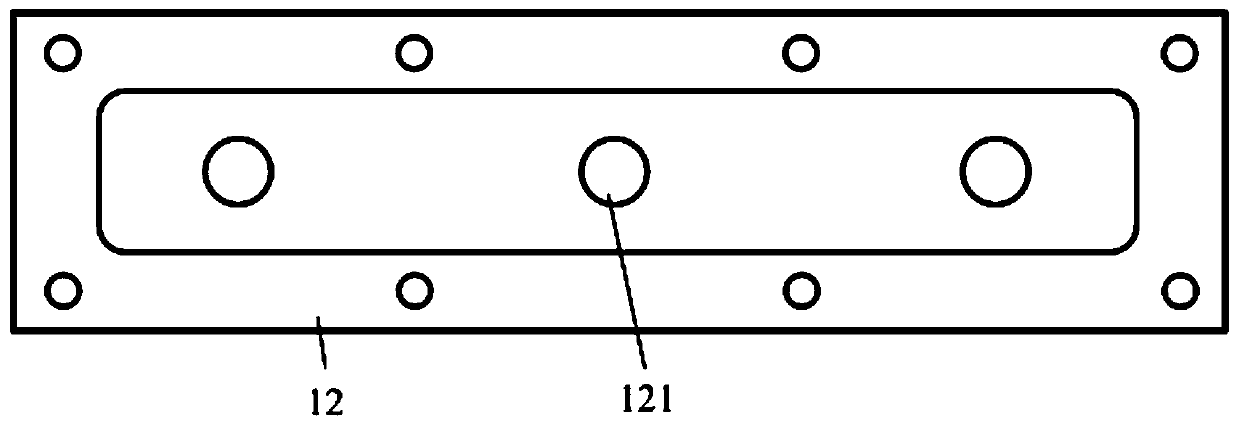

[0042] Such as figure 1 As shown, the present invention provides an embodiment of a tip-induced electrospinning nozzle, which includes a nozzle body 1, a spinning needle 2 and an airflow assist nozzle 3, and a liquid chamber 4 and an air chamber 5 are provided in the nozzle body 1 , the nozzle body 1 is provided with a liquid inlet 111 and a liquid outlet 121 communicating with the liquid chamber 4, and an air inlet 131 and an air outlet 132 communicating with the air chamber 5; the airflow assisting nozzle 3 is fixed It is located at the air outlet 132 and communicates with the air chamber 5; the spinning needle 2 is fixedly arranged at the liquid outlet 121 and communicates with the liquid chamber 4, and the free end of the spinning needle 2 passes through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com