LED chip packaging method and LED packaging structure using same

A technology of LED chip and packaging method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of complex process, large equipment investment, low production efficiency, etc., and achieve the effect of simple process and uniform light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Please refer to Figure 1A to Figure 1E , Figures 1A to 1E is a schematic diagram of the steps of the first embodiment of the LED chip packaging method of the present invention, and the LED chip packaging method of the first embodiment of the present invention includes the following steps:

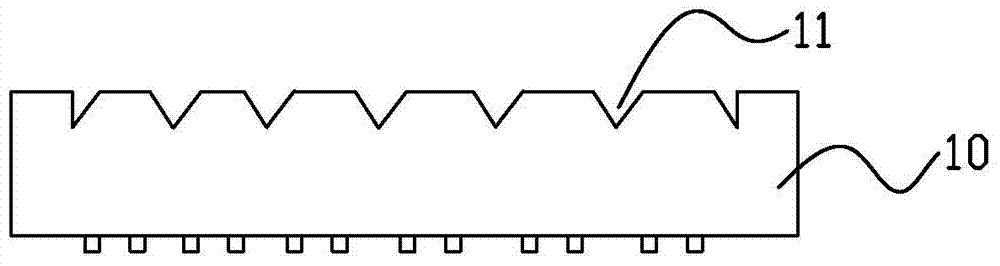

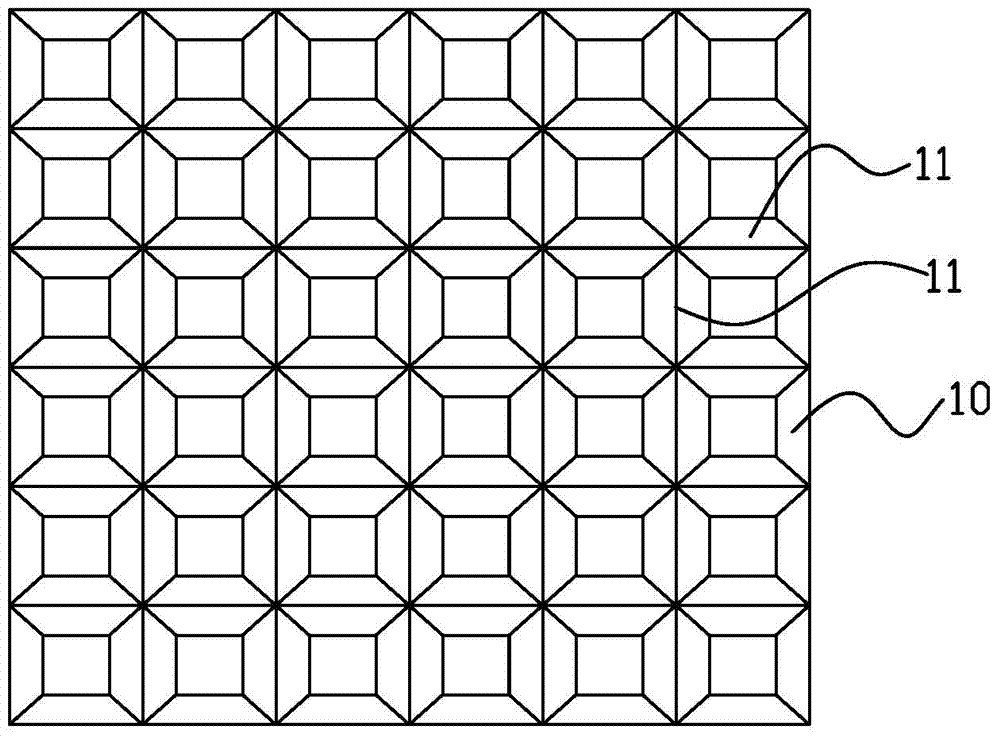

[0024] First, please refer to Figure 1A , Figure 1B , making an epitaxial wafer 10 of the LED chip, cutting and forming a groove 11 on the top of the epitaxial wafer 10;

[0025] These grooves 11 are V-shaped structures, these grooves 11 form a grid shape on the top of the epitaxial wafer 10, and each grid corresponds to each LED chip to be formed.

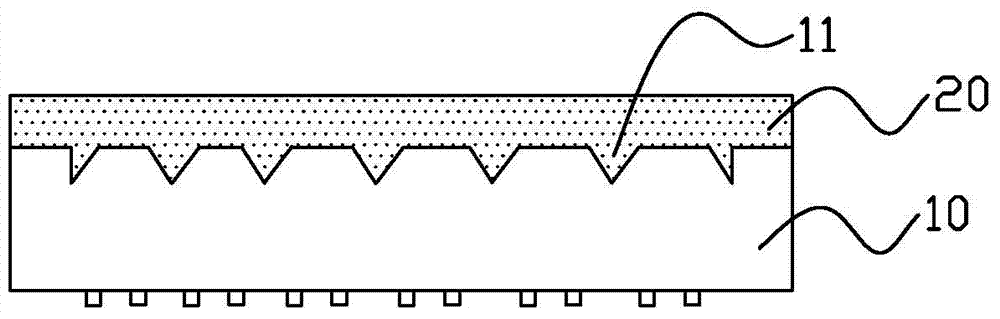

[0026] Second, please refer to Figure 1C , the top of the epitaxial wafer 10 is provided with a thin film 20;

[0027] Phosphor powder is mixed in the film 20, and the phosphor powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com