Magnesium ion battery cathode material of novel microstructure and preparation method thereof

A technology of magnesium ion battery and positive electrode material, applied in the field of new microstructured magnesium ion battery positive electrode material and its preparation, can solve the problems of low reversible capacity, poor rate performance, etc. The effect of porous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

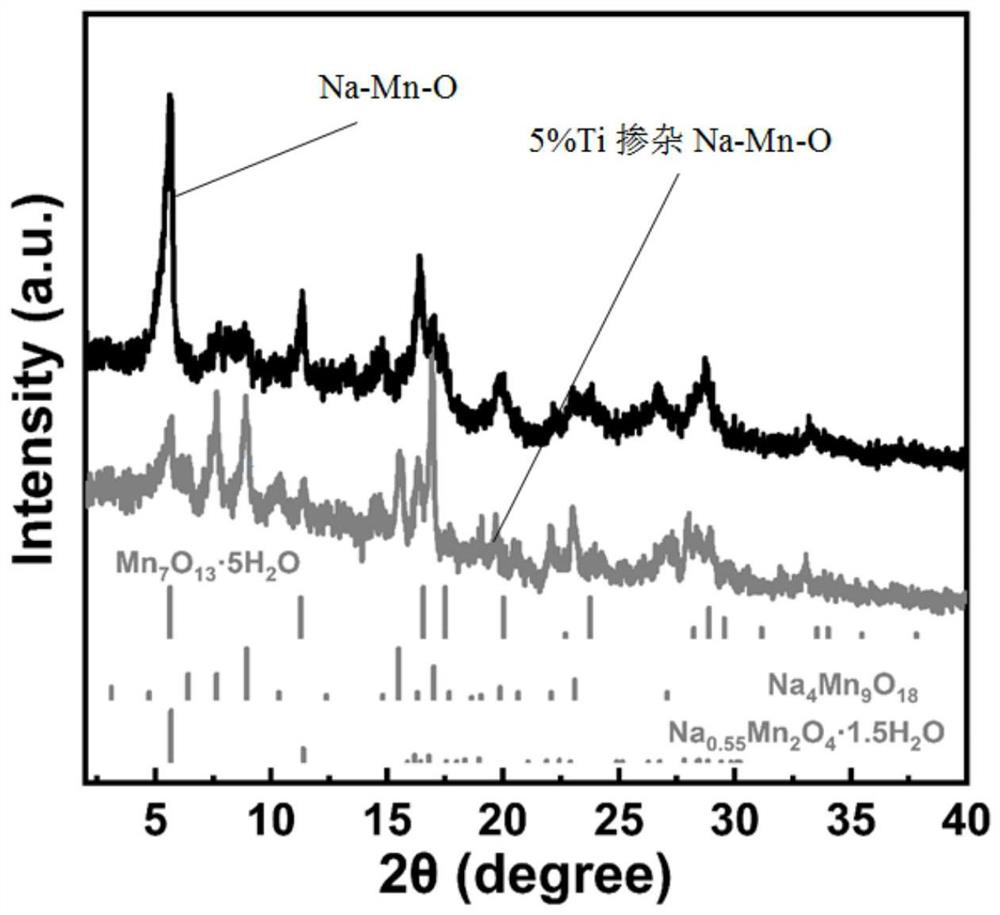

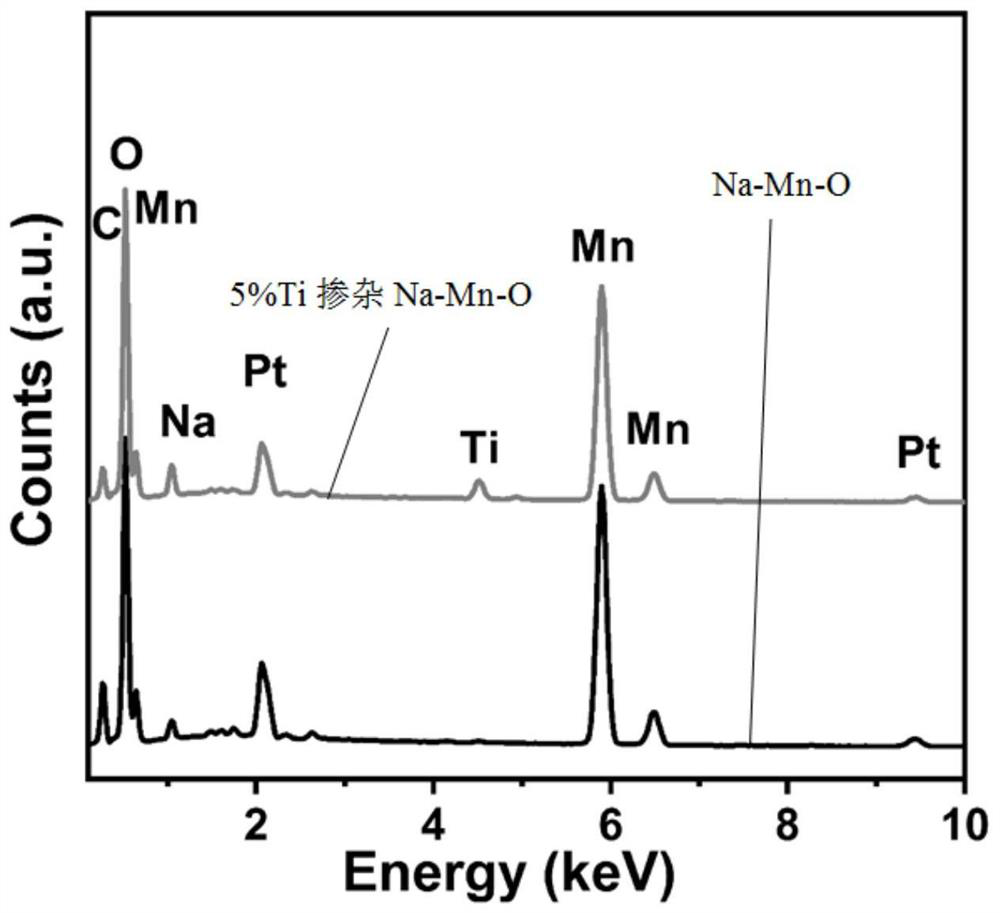

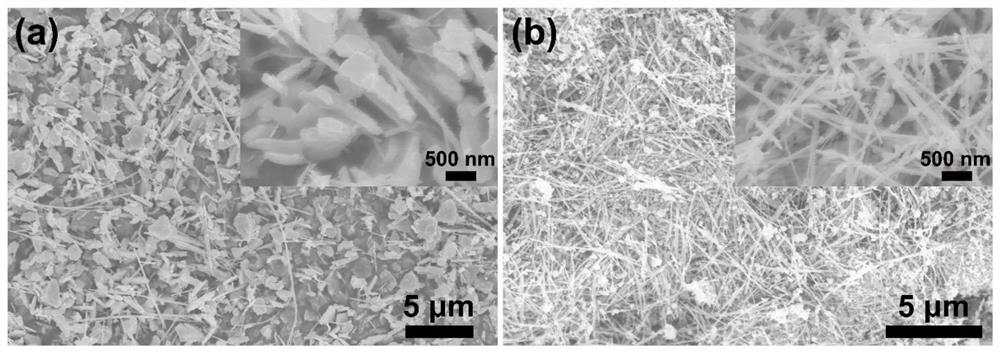

[0033] The preparation process of Na-Mn-O electrode material:

[0034] (1) Add 2 g of manganese trioxide and 0 g of titanium dioxide powder to 40 mL of 10 mol / L sodium hydroxide solution, and stir at 350 r / min for 30 min with a magnetic stirrer at room temperature until the powder dissolves.

[0035] (2) Move the solution obtained in (1) from the magnetic stirrer to an ultrasonic cleaner, ultrasonicate for 30 minutes at a power of 70W until it is completely dispersed, then move the fully dispersed solution to the magnetic stirrer again, and stir at a speed of 450r / min 30min.

[0036] (3) Move the completely dissolved solution into a hydrothermal synthesis reaction kettle, tighten the lid of the kettle, and move into a constant temperature oven. Heating at constant temperature at 170°C for 60h gave the preliminary product.

[0037] (4) Collect the preliminary product step by step into centrifuge tubes, place the centrifuge tubes symmetrically in the centrifuge, centrifuge at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com