Device and method for magnesium process flue gas desulfurization

A flue gas and air intake pipe technology, applied in the field of flue gas desulfurization, can solve the problems of high primary investment and operating costs, affecting desulfurization rate and utilization rate, large volume and occupied area, etc., to reduce investment and operating costs, large Effects of processing power, reduced footprint and equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

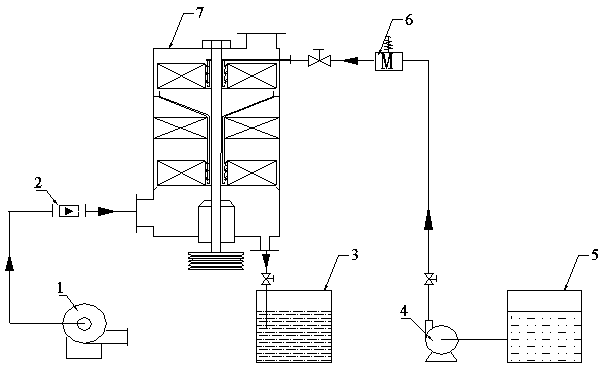

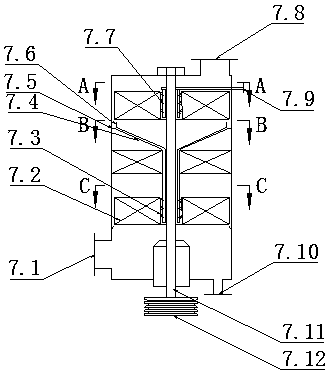

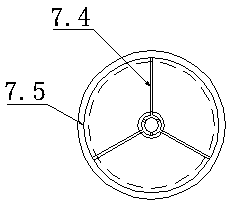

[0035] Such as Figure 1~5 As shown, the magnesium method flue gas desulfurization device includes a rotating packed bed absorber 7, the top of the rotating packed bed absorber 7 is provided with a gas outlet 7.8, the bottom is provided with a drain pipe 7.10, the upper side is connected to the liquid inlet pipe 7.9, and the lower side is connected to the inlet pipe. Gas pipe 7.1; rotating shaft 7.11 is provided in the middle of the rotating packed bed absorber 7, and a packing rotor 7.2 is provided at both ends of the middle part of the rotating shaft 7.11. The center of the packing rotor 7.2 is the lower liquid distributor 7.3 and the upper liquid distributor 7.7. The lower liquid distributor 7.3 and the upper liquid distributor 7.7 are connected to the liquid inlet pipe 7.9, and the lower end of the rotating shaft 7.11 extends to the outside of the absorber to connect to the frequency modulation motor 7.12; the inlet pipe 7.1 of the rotary packed bed absorber 7 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com