Impact type washing and drying integrated machine for shoes

An impact-type, all-in-one machine technology, which is applied in the cleaning, application, and household appliances of boots and shoes, can solve the problems of low washing efficiency, no drying function, and high-temperature damage to the shoe body, so as to promote the mass transfer process and avoid high temperature. Damage, the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

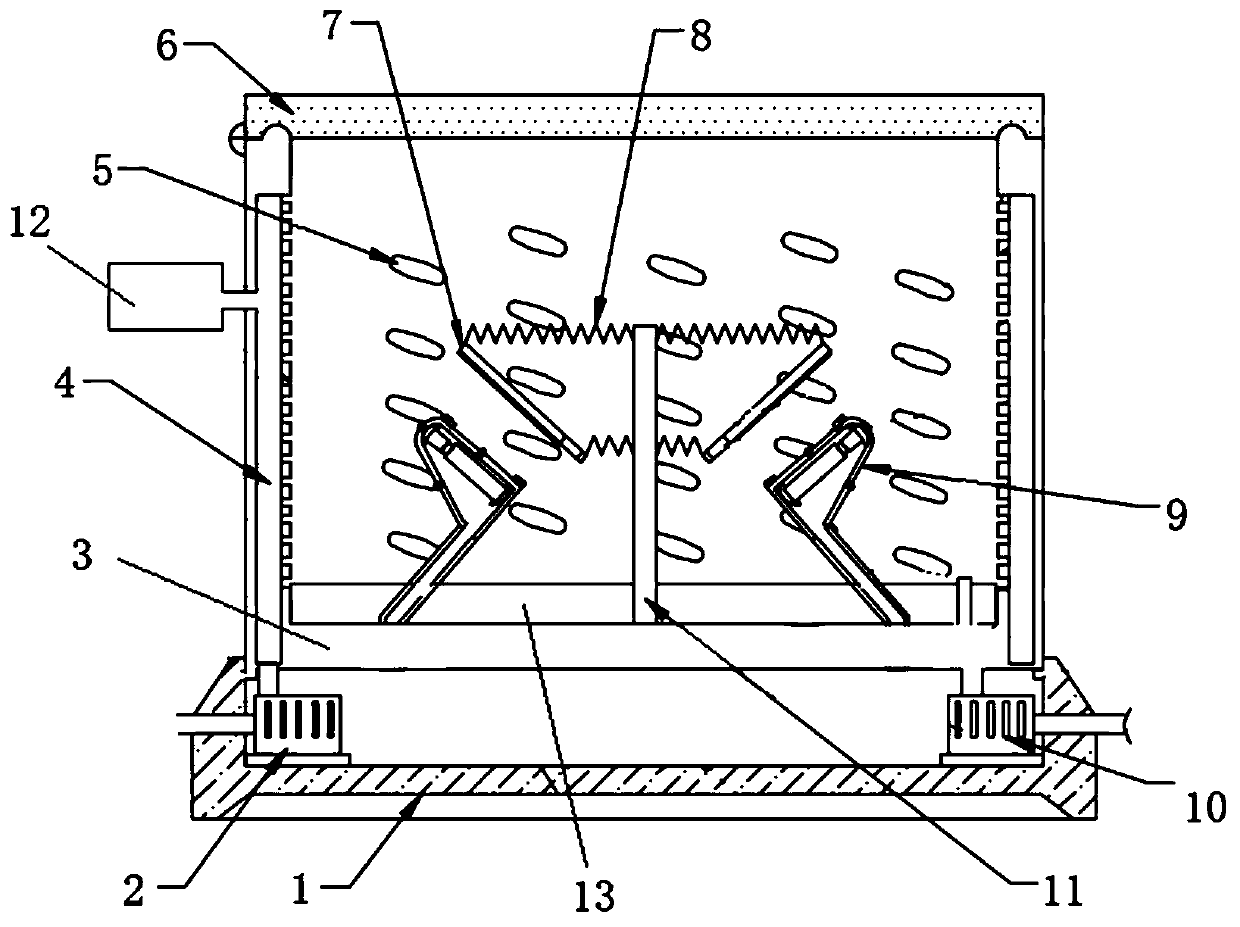

[0033] The impact washing and drying integrated machine for shoes in the present invention includes a base 1, a sealed cavity 3, a turntable 13, a shoe support frame 9, a pressure water nozzle 5, a water flow distributor 4, a water supply pump 2, a drainage pump 10, and a vacuum pump 12 and heater, see figure 1 .

[0034] The sealed chamber 3 is arranged above the base 1; the turntable 13 is arranged at the bottom of the sealed chamber 3; the shoe holder 9 is arranged on the turntable 13 and can rotate with the turntable 13; the pressure water nozzle 5 is distributed on the inner wall of the sealed chamber 3, and its The injection direction is parallel to the tangential direction when the turntable 13 rotates. The top of the sealing cavity 3 is an openable cover 6, through which the cover 6 can be taken out or put into the shoe body. The sealed cavity 3 is also provided with a vacuum degree sensor, and the vacuum degree sensor acquires the vacuum degree inside the sealed cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com