Metal mask electroforming equipment and electroforming fluid stirring device

A technology of stirring device and electroforming liquid, applied in electroforming, electrolysis process and other directions, can solve the problems of high cost, complexity, difficult installation and maintenance, etc., and achieve the effect of low cost, simple structure and good stirring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0040] Electroforming is a special processing method that uses the principle of electrochemical deposition of metals to accurately replicate some complex, fine or special-shaped workpieces. In the electroforming process, the uniformity of the thickness of the electroforming layer is related to factors such as current density, electroforming time, temperature, anode area, concentration of the electroforming solution, and stirring of the electroforming solution. In order to improve the quality of electroforming, it is necessary to strictly control the electroforming The temperature, ion concentration, and current density of the solution, and in order to avoid concentration polarization of the solution, rough surface of the workpiece or occurrence of pinholes, etc., the electroforming solution needs to be continuously filtered and stirred. In addition to accelerating the mixing of the solution and making the temperature and concentration uniform, stirring mainly promotes the mass ...

Embodiment approach 2

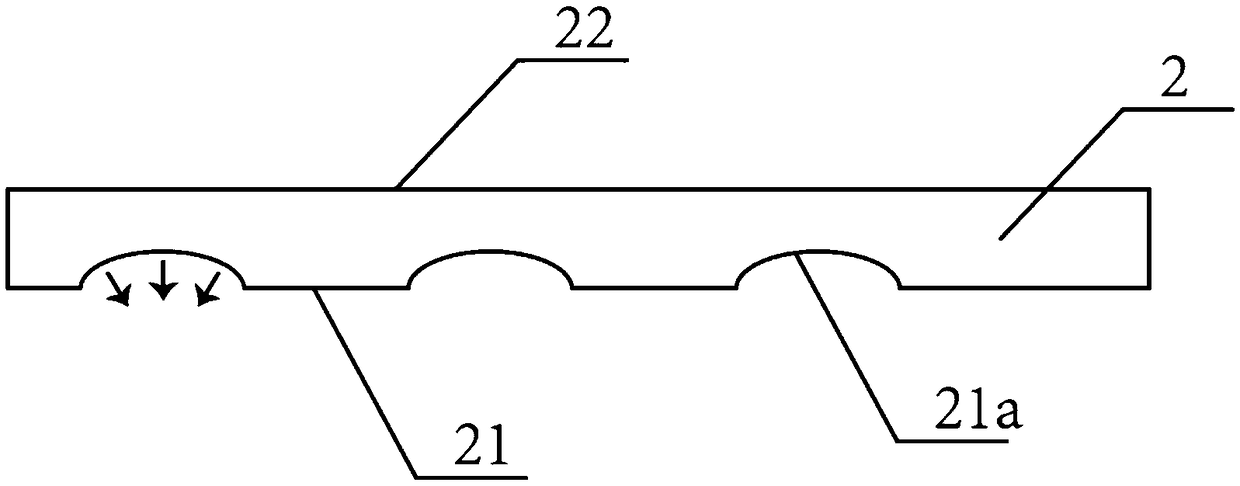

[0075] The second embodiment of the present application provides an electroforming liquid stirring device. The second embodiment is a further improvement of the first embodiment. The main improvement is that, in the second embodiment of the present application, see image 3 As shown, the liner 2 adopts a curved surface to further improve the convection effect of the electroforming liquid.

[0076] Wherein, the surface of the lining plate 2 perpendicular to the electroforming template is the first surface 21, and the surface opposite to the first surface 21 on the lining plate 2 is the second surface 22;

[0077] Several arc-shaped depressions 21a are formed on the first surface 21 .

[0078] Wherein, these depressions 21a can be randomly distributed on the first surface 21, and those skilled in the art can design the size of the depressions 21a according to factors such as the size of the electroforming tank and the density of the bath liquid.

[0079] The formed arc-shaped r...

Embodiment approach 3

[0081] The third embodiment of the present application provides an electroforming solution stirring device. The third embodiment is a further improvement of the second embodiment. The improvement is that in the third embodiment of the present application, see Figure 4 As shown, there are at least two depressions 21a, and the depressions 21a are arranged adjacent to each other so that the first surface 21 forms an approximately wavy curved surface.

[0082] When it is formed into a wavy curved surface, the tank liquids pushed by adjacent grooves can collide with each other to accelerate the mixing effect of the tank liquids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com