Method for preparing porous carbon nanosheet through pyrolysis of two-dimensional covalent organic framework

A technology of covalent organic framework and porous carbon, applied in the direction of nano-carbon, hybrid capacitor electrodes, etc., can solve the problem of low specific capacitance of porous carbon materials, achieve good conductivity and accelerate the mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

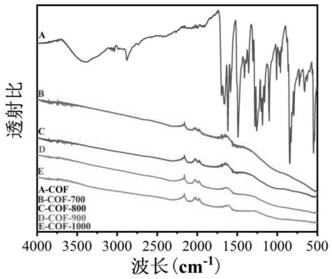

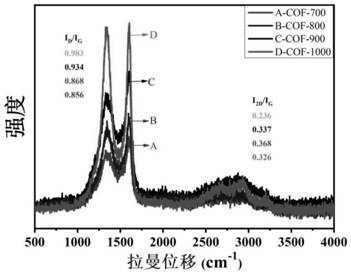

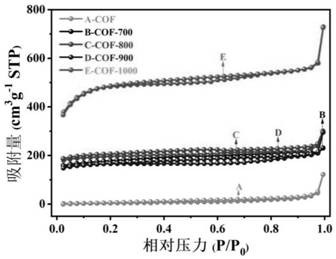

[0029] Embodiment 1: The method for preparing porous carbon nanosheets by pyrolysis of a two-dimensional covalent organic framework in this embodiment is carried out according to the following steps:

[0030] 1. Preparation of polymer: Weigh 2.23g (16mmol) of terephthalaldehyde and 2g (10.8mmol) of diaminodiphenyl ether and mix evenly, then add to 30mL of N,N-dimethylformamide (DMF ) and 30mL of N-methylpyrrolidone (NMP) in a mixed solvent, ultrasonically mixed for 15 minutes and then stirred for 15 minutes, under the protection of nitrogen, the oil bath was heated to 85°C to keep the reaction for 3 days, vacuum filtered, and After the solid phase was dried in vacuum at 80°C for 12 hours, the polymer DBEA was obtained, denoted as COF;

[0031] 2. Annealing: Put the polymer DBEA prepared in step 1 into a tube furnace, heat to 700, 800, 900, and 1000°C under nitrogen atmosphere, and keep it for 2 hours, then cool down to obtain porous carbon nanosheets, respectively record For ...

Embodiment 2

[0039] Embodiment 2: The method for preparing porous carbon nanosheets by pyrolysis of a two-dimensional covalent organic framework in this embodiment is carried out according to the following steps:

[0040] 1. Preparation of polymer: Weigh 2.23g (16mmol) of terephthalaldehyde and 1.16g (10.8mmol) of p-phenylenediamine and mix evenly, then add to 30mL of N,N-dimethylformamide (DMF ) and 30 mL of N-methylpyrrolidone (NMP), ultrasonically mixed for 15 minutes and then stirred for 15 minutes, under the protection of nitrogen, the oil bath was heated to 85 ° C to keep the reaction for 3 days, vacuum filtered, solidified After the phase was dried in vacuum at 80°C for 12 hours, the polymer DBDB was obtained;

[0041] 2. Annealing: Put the polymer DBDB prepared in step 1 into a tube furnace, heat to 900°C under nitrogen atmosphere and keep it for 2 hours, then cool down to obtain porous carbon nanosheets, which are designated as COF-900.

[0042] The scanning electron micrograph o...

Embodiment 3

[0043] Embodiment 3: The method for preparing porous carbon nanosheets by using two-dimensional covalent organic framework pyrolysis in this embodiment is carried out according to the following steps:

[0044] 1. Preparation of polymer: Weigh 1.5g (16mmol) of paraformaldehyde and 2g (10.8mmol) of diaminodiphenyl ether and mix evenly, then add to 30mL of N,N-dimethylformamide (DMF) Mixed with 30mL of N-methylpyrrolidone (NMP) in a mixed solvent, ultrasonically mixed for 15 minutes and then stirred for 15 minutes, under the protection of nitrogen, the oil bath was heated to 85 ° C to keep the reaction for 3 days, vacuum filtered, and in After vacuum drying at 80°C for 12 hours, the polymer DJEA was obtained;

[0045] 2. Annealing: put the polymer DJEA prepared in step 1 into a tube furnace, heat it to 900° C. under a nitrogen atmosphere and keep it for 2 hours, then cool down to obtain porous carbon nanosheets, which are designated as COF-900.

[0046] The scanning electron mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com