Device and method for preparing polysulfonamide nanometer fiber nets by means of airflow-electrostatic combination

A technology of nanofiber web and polysulfone amide, which is applied in fiber processing, stretch spinning, textiles and papermaking, etc., can solve the problems of high viscosity of polysulfone amide, low yield of electrospinning method, poor conductivity, etc., and achieve aggravated Evaporation speed, good market prospect, effect of droplet area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

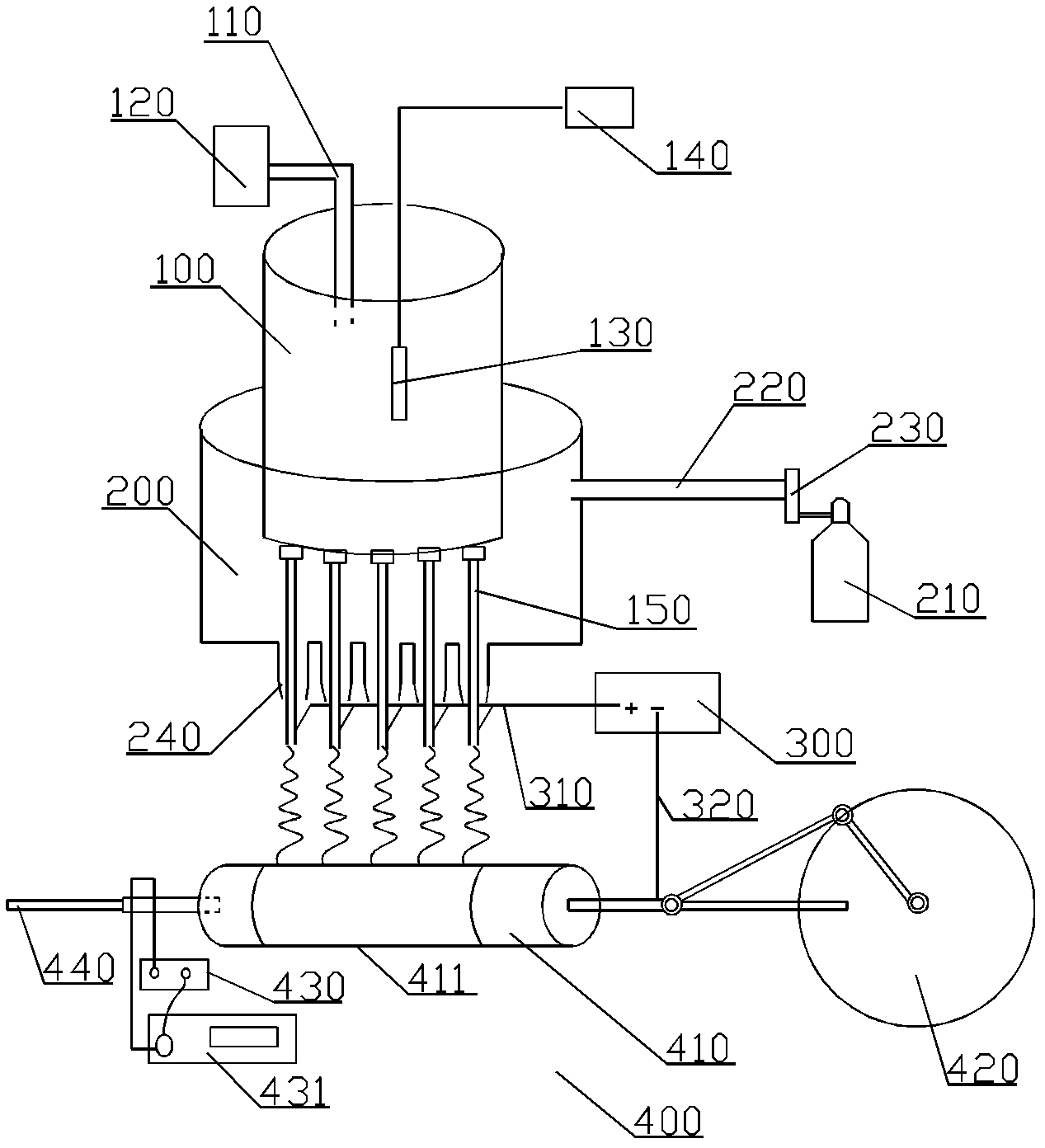

[0030] Such as figure 1 As shown, the air flow-electrostatic combination of the present invention prepares the device of polysulfone amide nanofibrous web, including liquid storage tank 100, gas chamber 200, electrostatic generator 300 and receiving device 400;

[0031] The liquid storage tank is connected to the external liquid supply device 120 through the infusion tube 110. The inside of the liquid storage tank is provided with a rod-shaped sensor 130. The rod-shaped sensor is connected to the ultrasonic generator 140. Several spinnerets 150 are arranged at the bottom of the liquid storage tank. The inner hole diameter is 0.4-1mm, the length is 8-12mm, and the spacing is 10mm; the distance between the spinneret and the receiving device is controlled at 5-25cm.

[0032] The gas chamber 200 is arranged outside the liquid storage tank and connected with the gas supply device. The gas supply device is a nitrogen cylinder 210. The gas chamber is connected to the gas chamber thro...

Embodiment 2

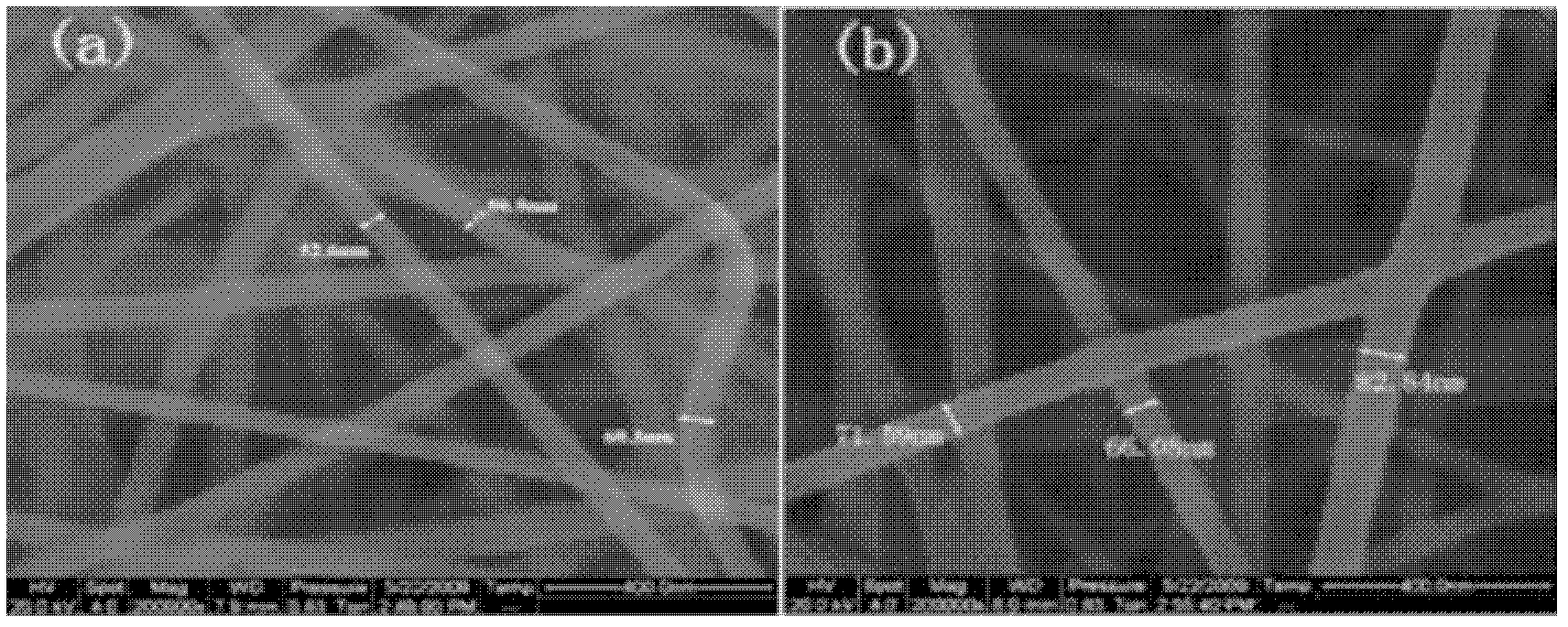

[0044] This embodiment is basically the same as Embodiment 1, the difference is that no air flow is introduced into this embodiment. Observing the spinning process, it is found that the number of droplets is large and the phenomenon of needle blockage is serious. The fiber external structure morphology of the prepared polysulfone amide nanofiber web is as follows: figure 2 (b). The average diameter of the polysulfoneamide nanofibers prepared by testing is 85nm, the dispersion of fiber diameter distribution is small, mainly concentrated at 75-150nm, and the specific surface area of the fibers is 35.6m 2 / g, the output of polysulfoneamide nanofibers is 6.1mg / h.

Embodiment 3

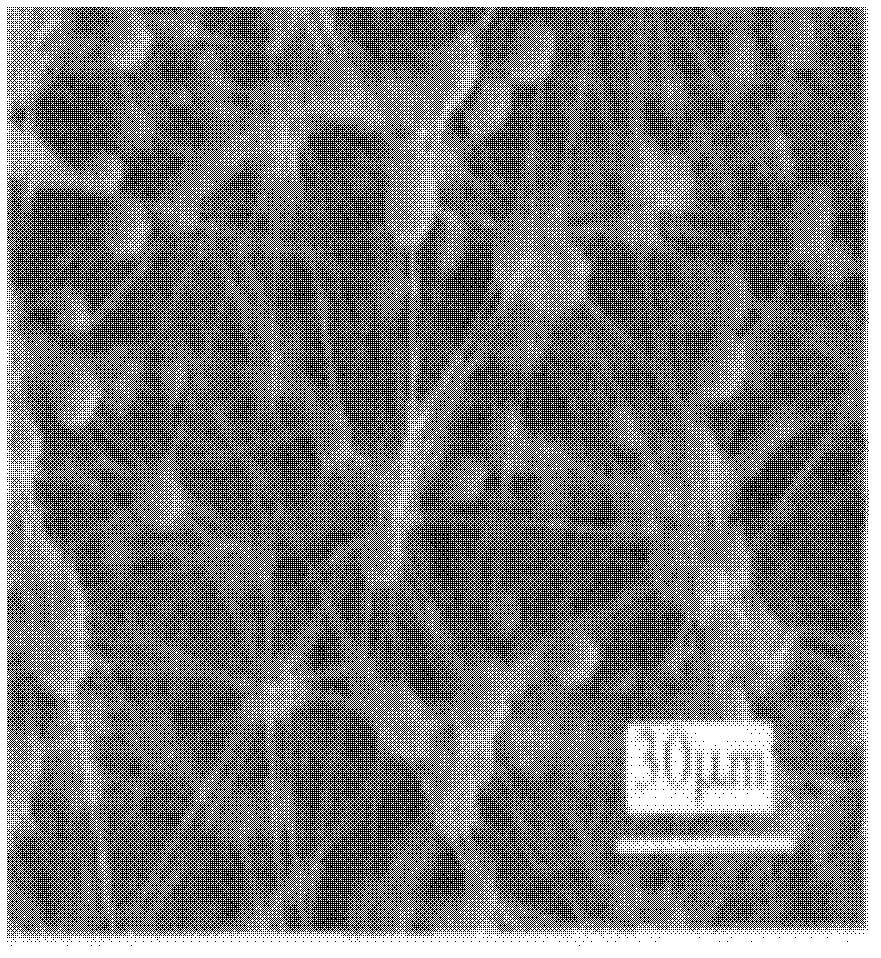

[0046] This embodiment is basically the same as Embodiment 1, the difference is that the ultrasonic generator is not turned on in this embodiment. The fiber external structure morphology of the prepared polysulfone amide nanofiber web is as follows: image 3 As shown, bead fibers can be found, and the output of polysulfoneamide nanofibers is 2.5mg / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com