Fluorine-containing magnesium oxide pellet ore

A technology for magnesium oxide pellets and content, which is applied in the field of metallurgy to achieve the effects of decreasing expansion rate, increasing dripping temperature and improving blast furnace production indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

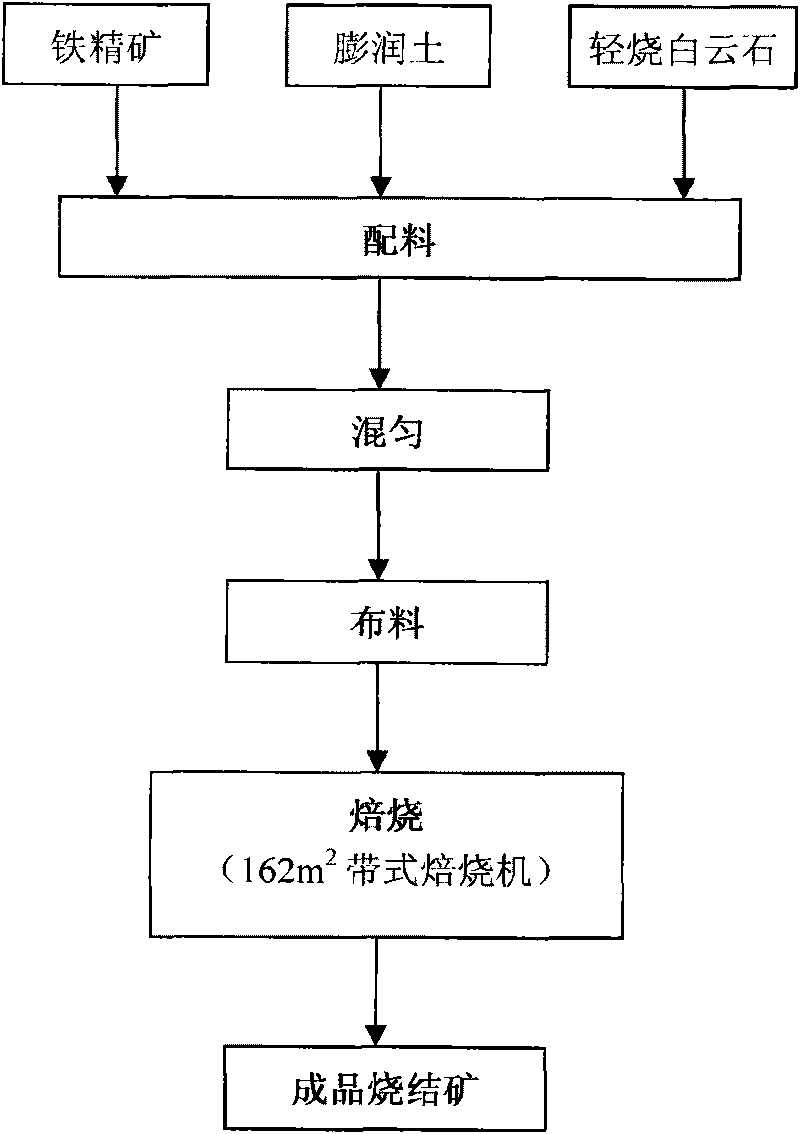

[0016] Adopt 162m 2 The belt roaster produces fluorine-containing magnesium oxide pellets.

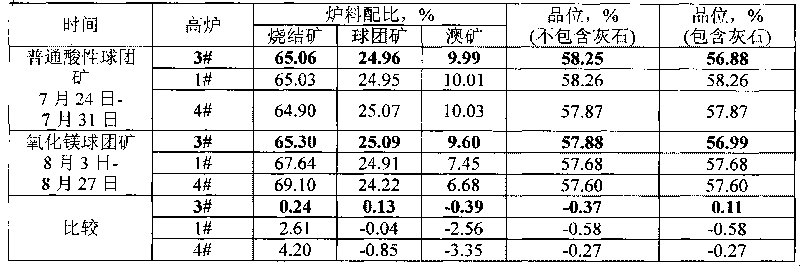

[0017] The fluorine-containing magnesium oxide pellets of the present invention use iron concentrate as the main material, light-burned dolomite as the flux, and bentonite as the binder for processing. Iron concentrate+50wt% purchased domestic iron concentrate, Bayan Obo mixed iron concentrate is composed of 70wt% Bayan Obo iron concentrate+30wt% purchased domestic ordinary iron concentrate; bentonite accounts for 1.0%~1.2wt% in the raw material , Light burning dolomite accounts for 3% to 4wt% in the raw material.

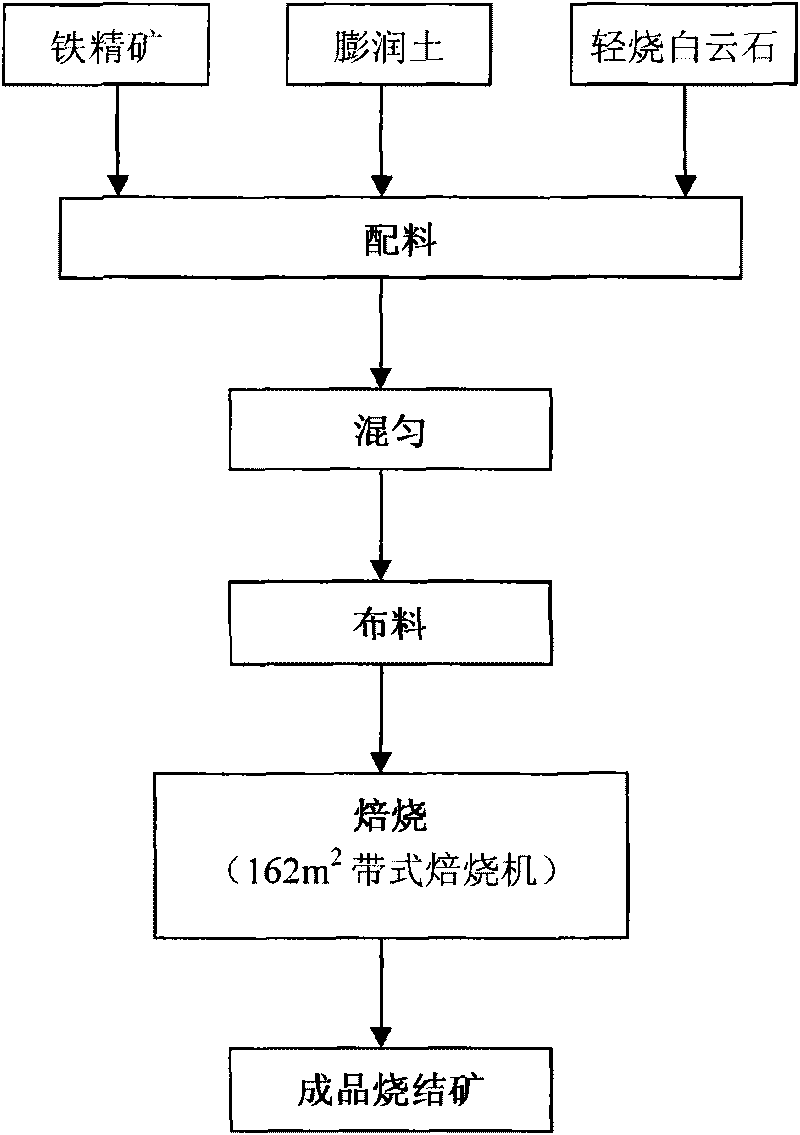

[0018] Referring to the attached drawings, firstly, the iron ore concentrate, bentonite and light-burned dolomite are proportioned in the proportioning room, and the prepared mixture is mixed by a strong mixer, and then enters the pelletizing disc to make pellets. The 8-16mm green pellets are distributed on the belt roaster, and through five stages of drying, preheating, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com