Rapid ground leveling mortar

A leveling mortar and fast technology, applied in the field of leveling mortar, can solve the problems of low construction efficiency, low early strength, and easy cracking cost of leveling mortar, and achieve the effect of high construction efficiency, high density and small shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 250 parts of 42.5 grade rapid hardening sulfoaluminate cement, 597 parts of 10-140 mesh river sand, 140 parts of slag powder, 0.6 part of water reducer, 0.4 part of hydroxypropyl cellulose ether, 1 part of borax, 0.4 part of lithium carbonate , 0.5 parts of defoamer, and 10 parts of latex powder are put into the mixer and stirred evenly, and the ground quick leveling mortar powder is obtained.

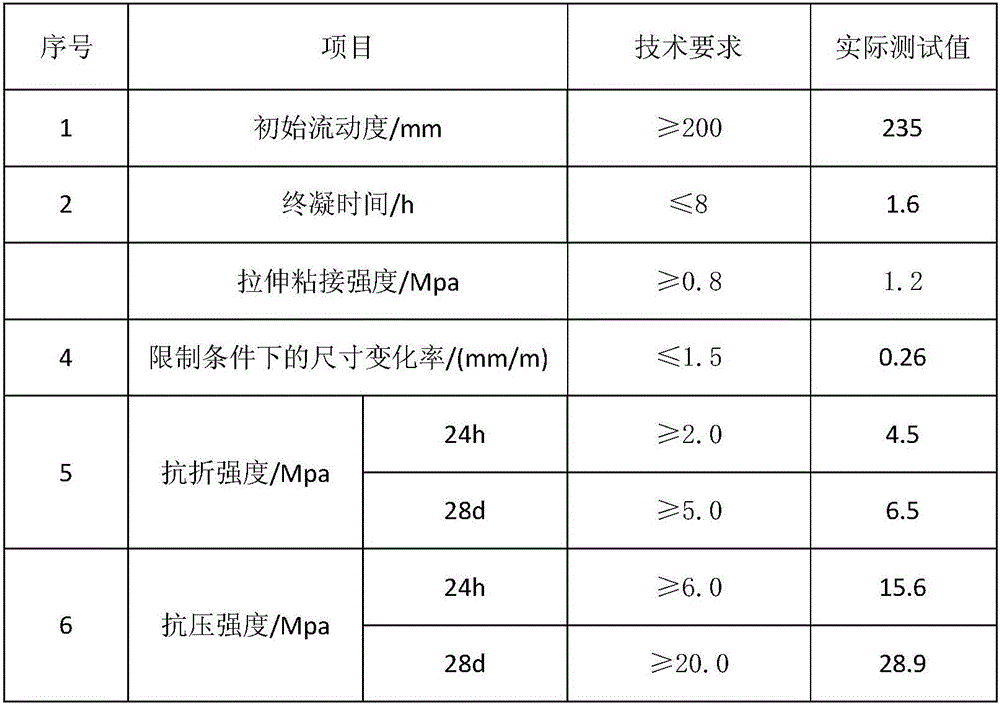

[0020] During the test, the ratio of powder to water during the construction of the prepared ground quick leveling mortar was 1:0.2, and the performance indicators tested according to the building materials industry standard of the People's Republic of China (JC / T 2326-2015 leveling mortar for construction) are shown in Table 1:

[0021] Table 1-Example 1 prepared ground rapid leveling mortar test results

[0022]

Embodiment 2

[0024] Mix 200 parts of 42.5 grade quick-hardening sulfoaluminum salt cement, 50 parts of portland cement, 588 parts of 10-140 mesh river sand, 150 parts of heavy calcium powder, 10 parts of metakaolin, 0.6 parts of water reducer, 0.3 parts of hydroxypropyl Put cellulose ether, 0.2 part of lithium sulfate, 0.5 part of tartaric acid, and 0.5 part of defoamer into a mixer and stir evenly to obtain ground quick leveling mortar powder.

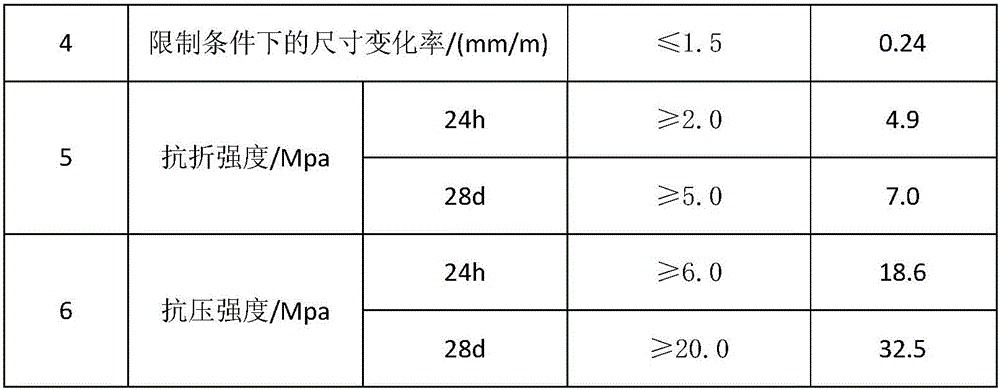

[0025] During the test, the ratio of powder to water during the construction of the prepared ground quick leveling mortar was 1:0.2, and the performance indicators tested according to the building materials industry standard of the People's Republic of China (JC / T 2326-2015 leveling mortar for construction) are shown in Table 2:

[0026] Table 2-Example 2 prepared ground rapid leveling mortar test results

[0027]

[0028]

Embodiment 3

[0030] 250 parts of 42.5-grade quick-hardening sulfur-aluminum salt cement, 597.5 parts of 10-140 mesh river sand, 140 parts of heavy calcium powder, 10 parts of metakaolin, 0.8 parts of water reducer, 0.4 parts of hydroxypropyl cellulose ether, 0.2 parts of sulfuric acid Lithium, 0.5 parts of sodium gluconate, and 0.6 parts of defoamer are put into a mixer and stirred evenly to obtain ground quick leveling mortar powder.

[0031] During the test, the ratio of powder to water during the construction of the prepared ground quick leveling mortar was 1:0.2, and the performance indicators tested according to the building materials industry standard of the People's Republic of China (JC / T 2326-2015 building leveling mortar) are shown in Table 3:

[0032] Table 3-Example 3 prepared ground rapid leveling mortar test results

[0033]

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com