High-polymer modified water-emulsion asphalt-based waterproof paint and preparation method thereof

A polymer modified, waterproof coating technology, applied in asphalt coatings, chloroprene homopolymer coatings, epoxy resin coatings, etc., can solve the problem of substrate adhesion, material ductility is not very good, time-consuming and labor-intensive, etc. problems, achieve the effect of improving anti-ultraviolet aging function, improving low-temperature performance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

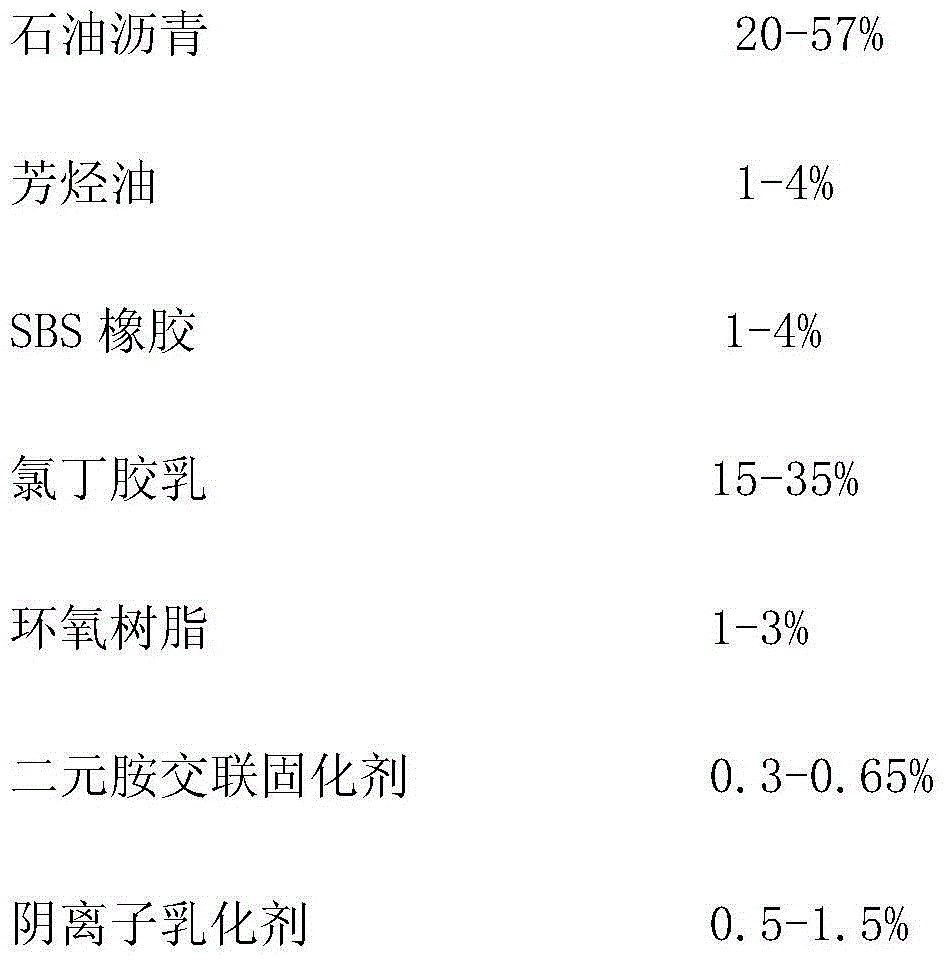

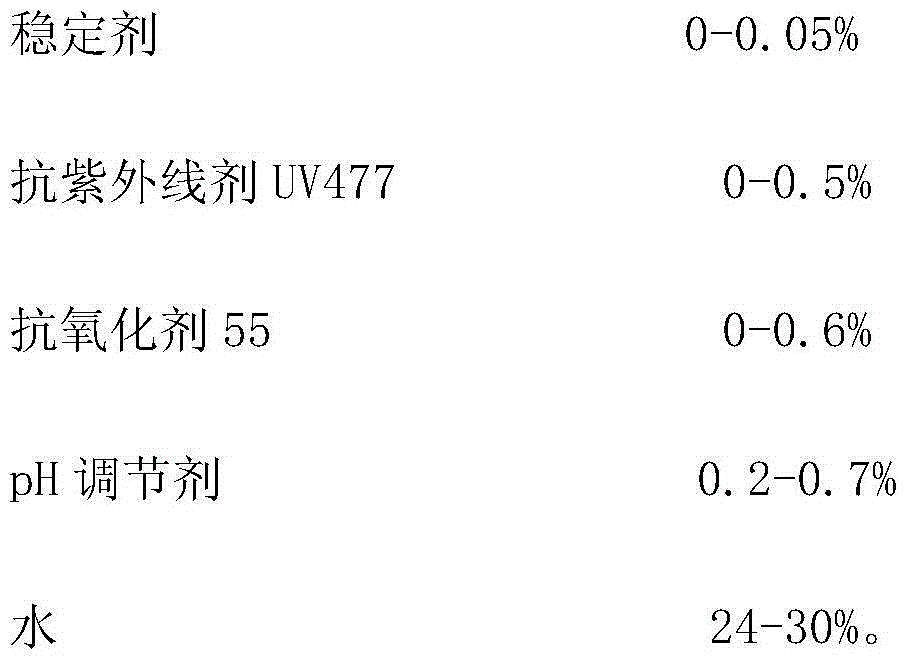

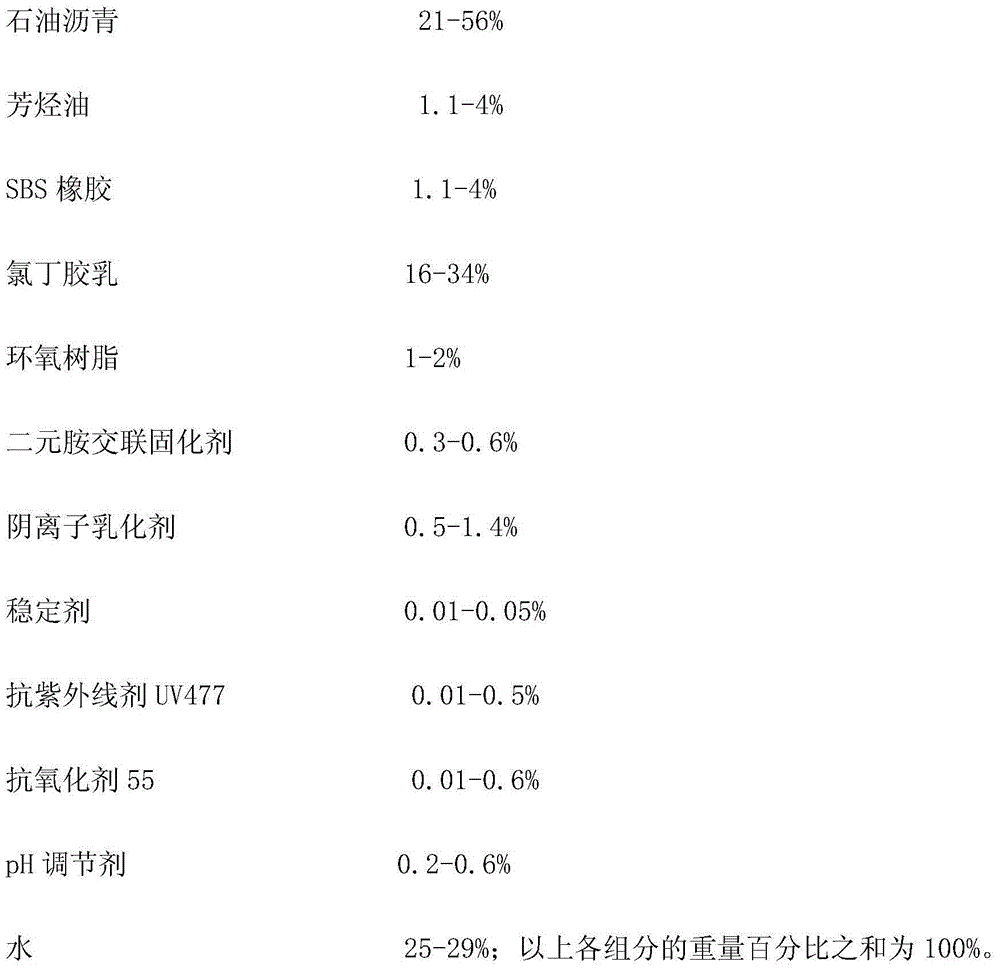

Method used

Image

Examples

Embodiment 1

[0031] Component A: Pump 100# special asphalt for waterproof materials into the asphalt tank and heat it to 160℃~180℃, pump in 2% aromatic oil, then add 2% SBS rubber and 1% epoxy resin E-51, stir for 30 Minutes later, it was ground by a colloid mill, and the prepared modified asphalt material was stirred and developed for 2 hours, and then used. Pump hot water at 60°C into the soap tank, add 1% of tall oil anionic emulsifier (tal oil or sulfonated tall oil soap or sodium rosinate), 0.02% of AEO-9 and ethylene glycol Amine 0.6%, at the same time use NaOH to adjust the pH value to 11 to make soap. The prepared polymer modified asphalt and soap solution are simultaneously passed through a high-speed shearing machine to form a modified emulsified asphalt emulsion with a concentration of about 60%. Add 25% neoprene latex to the emulsion, and then add 0.4% and Xinglu brand anti-ultraviolet agent UV477 and 0.5% Hexing deer brand antioxidant 55 should be stirred slowly to disperse e...

Embodiment 2

[0034] Component A: Pump 90# heavy traffic asphalt into the asphalt tank and heat it to 160℃~180℃, pump in 3% aromatic oil, then add 2% SBS rubber and 1% epoxy resin E-44, and stir for 30 minutes After grinding by a colloid mill, the prepared modified asphalt material was stirred and grown for 2 hours, and then used. Pump hot water at 60°C into the soap tank, add 1% of tall oil anionic emulsifier (sulfonated succinic acid or sulfonated rosin), 0.02% of AEO-9 and 0.6% of ethylenediamine, and use NaOH adjusts the pH to 11 to make soap. The prepared polymer modified asphalt and soap solution are simultaneously passed through a high-speed shearing machine to form a modified emulsified asphalt emulsion with a concentration of about 60%. Add 25% neoprene latex to the emulsion, and then add 0.4% and Xinglu brand anti-ultraviolet agent UV477 and 0.5% Hexing deer brand antioxidant 55 should be stirred slowly to disperse evenly during the feeding process. After feeding is completed, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com