Lightweight energy-saving paint and its preparation method

An energy-saving coating and lightweight filler technology, applied in the field of material science, can solve the problems of low strength, poor volume stability, and low refractory temperature, and achieve the effects of high refractoriness, good fluidity, and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

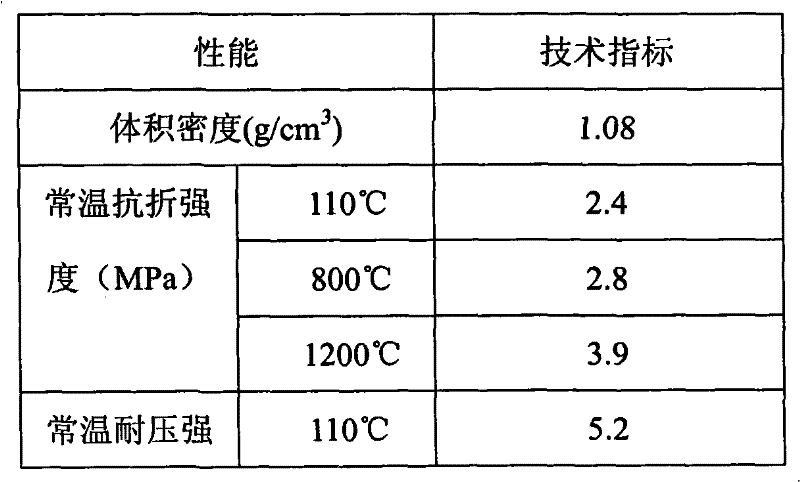

[0017] This implementation example provides a light-weight energy-saving coating that can be applied to high-temperature pipelines and its preparation method. The raw materials and mass ratios used are 55 kg of corundum hollow balls, 10 kg of floating beads, 15 kg of bentonite, and mullite fiber 5 kg, 15 kg of water glass binder with a modulus of 2.5, plus 5 kg of sodium fluorosilicate additive. The preparation process of the lightweight energy-saving paint comprises the following steps: (1) mixing water glass and mullite fiber evenly; (2) adding corundum hollow spheres and stirring evenly; (3) adding bentonite and floating beads and mixing evenly; (4) Add sodium fluorosilicate and mix well 0.5 hours before use. The light-weight energy-saving paint in this implementation example should be applied by manual application, and the performance indicators of the prepared light-weight energy-saving paint are shown in Table 1.

[0018] Table 1 Performance indicators of the light-weig...

Embodiment 2

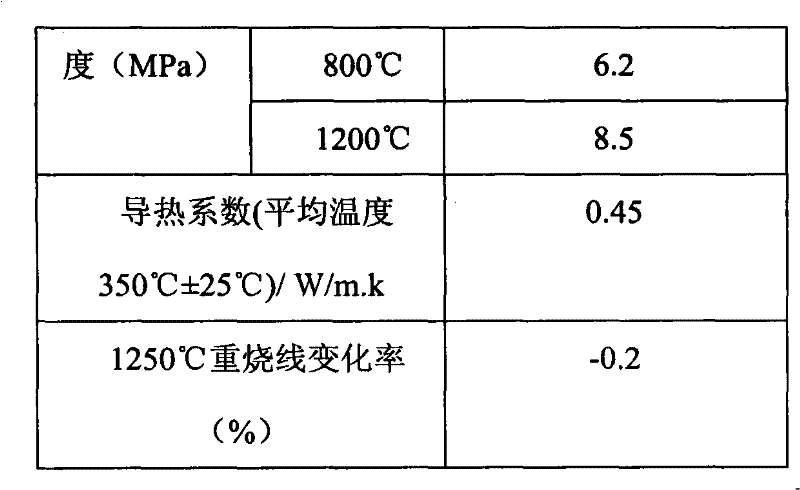

[0022] This implementation example provides a light-weight energy-saving coating that can be applied to high-temperature kilns and its preparation method. The raw materials and mass ratios used are 45 kg of corundum hollow spheres, 15 kg of hollow glass microspheres, and 10 kg of hollow ceramic microspheres. kg, 10 kg of glass fiber, 20 kg of calcium aluminate cement, 15 kg of water, and 0.5 kg of sodium tripolyphosphate additive. The preparation process of the lightweight energy-saving paint includes the following steps: (1) mixing water, calcium aluminate cement and glass fiber evenly; (2) adding corundum hollow balls and stirring evenly; (3) adding hollow glass microspheres, hollow ceramic microspheres Mix the beads evenly; (4) add sodium tripolyphosphate 1 hour before use and mix well. The light-weight energy-saving coating in this implementation example should be applied by the construction method of vibration pouring, and the performance indicators of the prepared light-...

Embodiment 3

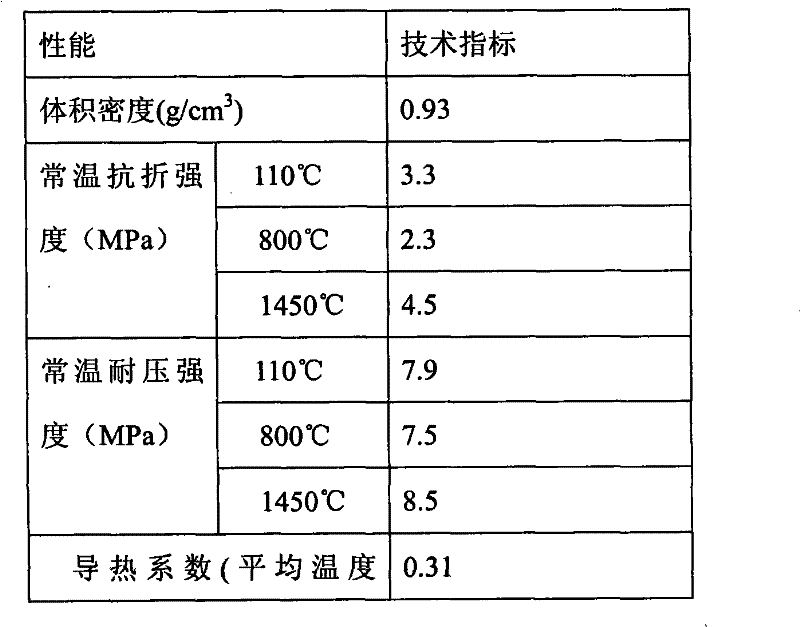

[0027] This implementation example provides a light-weight energy-saving coating that can be applied to ladles and its preparation method. The raw materials and mass ratios used are 50 kg of corundum hollow balls, 20 kg of diatomite, 10 kg of perlite, and 3 kg of asbestos. , 2 kg of rock wool, 15 kg of high alumina cement, 20 kg of water, and 0.5 kg of sodium hexametaphosphate additive. The preparation process of the lightweight energy-saving paint includes the following steps: (1) mix water, high alumina cement, asbestos, and rock wool evenly; (2) add corundum hollow balls and mix evenly; (3) add diatomite and perlite to mix Uniform; (4) Add sodium hexametaphosphate 1 hour before use and mix well. The light-weight energy-saving coating in this implementation example should be applied by the construction method of vibration pouring, and the performance indicators of the prepared light-weight energy-saving coating are shown in Table 3.

[0028] Table 3 Performance indicators o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com