Method for preparing direct methanol fuel cell membrane electrode

A methanol fuel cell and membrane electrode technology, which is applied to fuel cells, battery electrodes, fuel cell components, etc., can solve problems such as hindering methanol and air product transport, reducing the porosity of the support layer, and reducing the utilization rate of catalysts. Improve mass transfer resistance, reduce mass transfer resistance, improve the effect of interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Membrane preparation and pretreatment. The Nafion membrane is Nafion115 produced by Du Pont Company of the United States, and the ion form is proton type. The membrane needs to be pretreated before use: a Nafion membrane of a certain size in a volume ratio of 5% H 2 o 2 Treat in aqueous solution at 80°C for 1 hour to remove organic matter on the surface of the membrane, then place it in double distilled water at 80°C for 1 hour to wash the hydrogen peroxide on the surface of the membrane, and then use 0.5mol L at 80°C -1 h 2 SO 4 Inorganic metal ions were treated with an aqueous solution, and then placed in double distilled water at 80 °C for 1 hour to wash the H on the surface of the membrane. 2 SO 4 , the treated Nafion membrane was placed in double distilled water for later use.

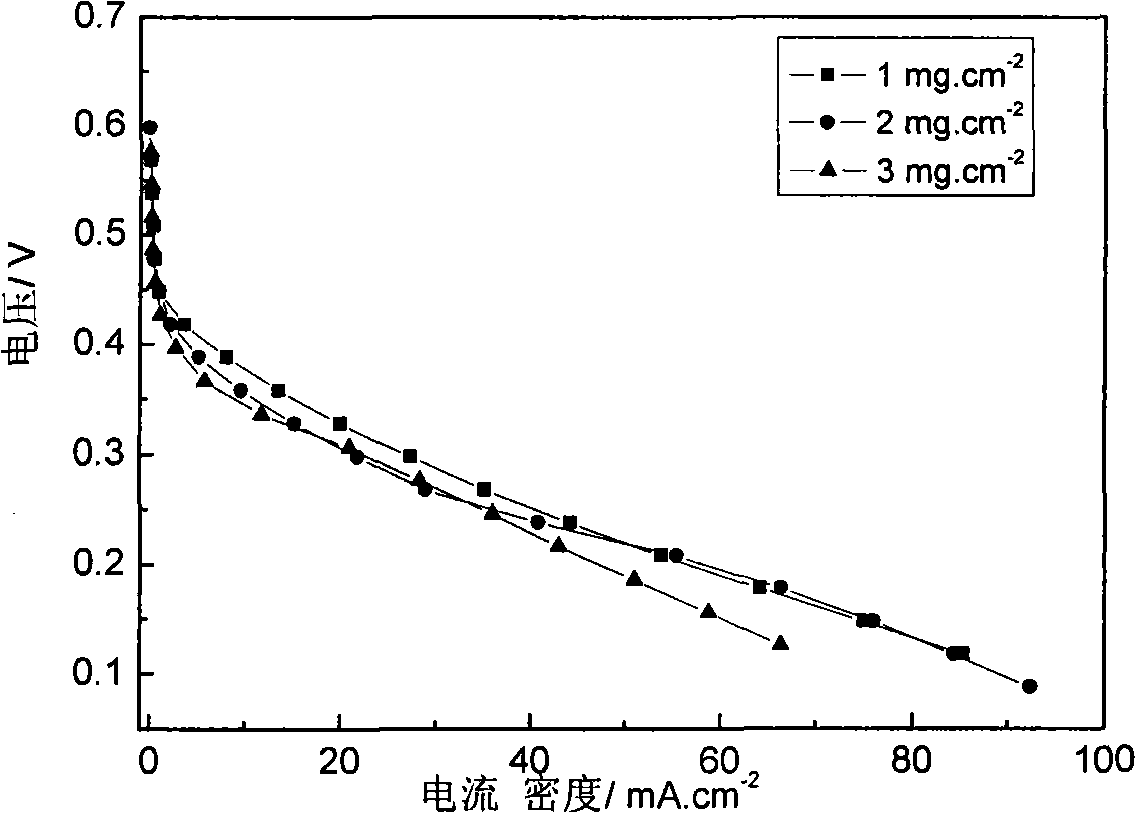

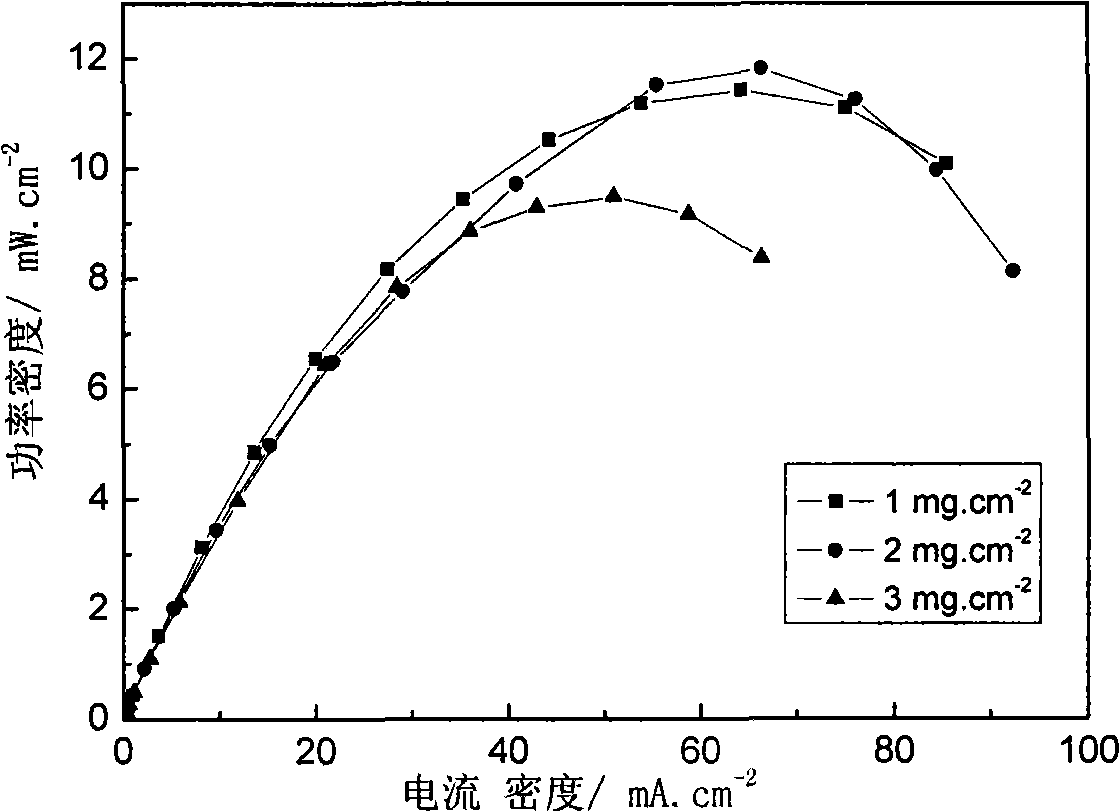

[0029] 2. Preparation of catalyst slurry and preparation of cathode and anode catalyst layers. The anode and cathode were respectively selected PtRu black catalyst and Pt Black c...

Embodiment 2

[0035] 1. Membrane preparation and pretreatment. The Nafion membrane is Nafion115 produced by Du Pont Company of the United States, and the ion form is proton type. The membrane needs to be pretreated before use: a Nafion membrane of a certain size in a volume ratio of 5% H 2 o 2 Treat in aqueous solution at 80°C for 1 hour to remove organic matter on the surface of the membrane, then place it in double distilled water at 80°C for 1 hour to wash the hydrogen peroxide on the surface of the membrane, and then use 0.5mol L at 80°C -1 h 2 SO 4 Inorganic metal ions were treated with an aqueous solution, and then placed in double distilled water at 80 °C for 1 hour to wash the H on the surface of the membrane. 2 SO 4 , the treated Nafion membrane was placed in double distilled water for later use.

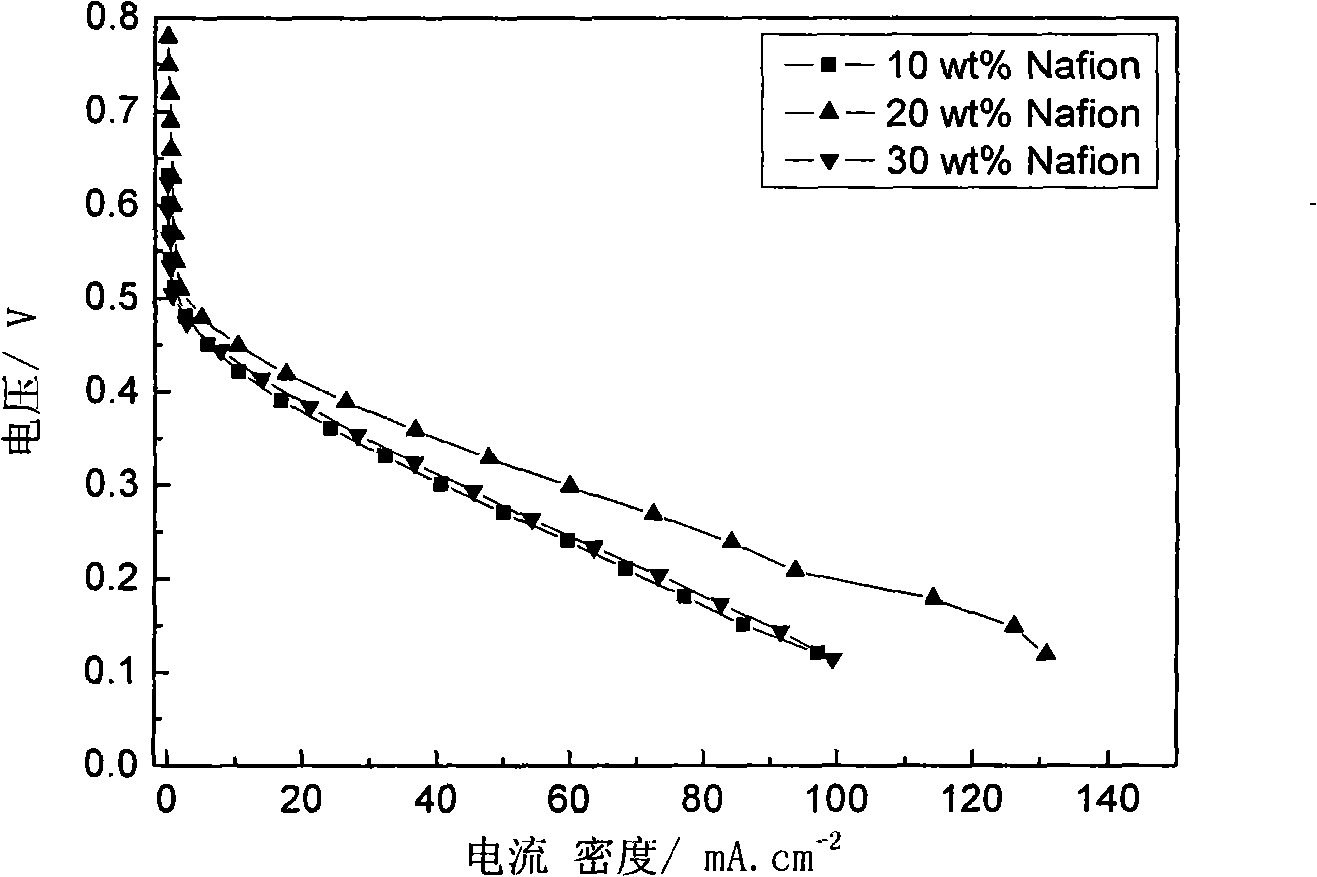

[0036] 2. Preparation of catalyst slurry and preparation of cathode and anode catalyst layers. 20wt% PtRu / C catalyst and 20wt% Pt / C catalyst were selected as raw materials for the...

Embodiment 3

[0042] 1. Membrane preparation and pretreatment. The Nafion membrane is Nafion115 produced by Du Pont Company of the United States, and the ion form is proton type. The membrane needs to be pretreated before use: a Nafion membrane of a certain size in a volume ratio of 5% H 2 o 2 Treat in aqueous solution at 80°C for 1 hour to remove organic matter on the surface of the membrane, then place it in double distilled water at 80°C for 1 hour to wash the hydrogen peroxide on the surface of the membrane, and then use 0.5mol L at 80°C -1 h 2 SO 4 Inorganic metal ions were treated with an aqueous solution, and then placed in double distilled water at 80 °C for 1 hour to wash the H on the surface of the membrane. 2 SO 4 , the treated Nafion membrane was placed in double distilled water for later use.

[0043] 2. Preparation of catalyst slurry and preparation of cathode and anode catalyst layers. 40wt% PtRu / C catalyst and 40wt% Pt / C catalyst were selected as raw materials for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com