High-purity, high-alkali-resistance and low-thermal-expansion silicon bricks using cristobalite as main crystal phase and production method thereof

A low thermal expansion, pure square technology, applied in the field of refractory material manufacturing, can solve the problems of high impurity content, incomplete crystal transformation, poor alkali erosion resistance, etc., achieve high alkali resistance, improve thermal shock stability, and low expansive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

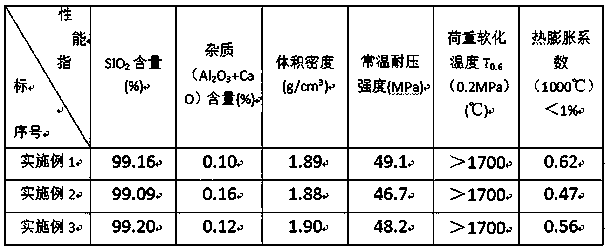

Examples

Embodiment 1

[0028] A high-purity cristobalite high-alkali-resistant low-thermal-expansion silica brick, the particle size composition and addition ratio of each raw material are:

[0029] 40 parts of fused silica aggregate with particle size ≤5mm, 51 parts of fused silica fine powder with particle size ≤0.09mm, zirconium-containing SiO with particle size ≤0.001mm 2 3 parts of fine powder, 3 parts of nano-silica sol binder, 1 part of boric acid fine powder, 1.5 parts of dextrin, 0.5 parts of sodium tripolyphosphate and sodium hexametaphosphate binder.

Embodiment 2

[0031] A high-purity cristobalite high-alkali-resistant low-thermal-expansion silica brick, the particle size composition and addition ratio of each raw material are:

[0032] 35 parts of fused silica aggregate with particle size ≤5mm, 53 parts of fused silica fine powder with particle size ≤0.09mm, zirconium-containing SiO with particle size ≤0.001mm 2 5 parts of fine powder, 4 parts of nano-silica sol binder, 1.5 parts of boric acid fine powder, 1 part of dextrin, 0.5 parts of sodium tripolyphosphate and sodium hexametaphosphate binder.

Embodiment 3

[0034] A high-purity cristobalite high-alkali-resistant low-thermal-expansion silica brick, the particle size composition and addition ratio of each raw material are:

[0035] 44 parts of fused silica aggregate with a particle size of ≤5mm, 43 parts of fused silica fine powder with a particle size of ≤0.09mm, zirconium-containing SiO with a particle size of ≤0.001mm 2 8 parts of fine powder, 2 parts of nano-silica sol binder, 2.5 parts of boric acid fine powder, and 0.5 part of dextrin.

[0036]The preparation process of embodiments 1, 2, and 3 is as follows: batching is carried out according to the above ratio, after the weighed materials are dry-mixed in a mixing mixer for 5-10 minutes, the added liquid additive mixture is wet-mixed for 10 minutes, and then mixed at a high speed for 10 minutes. minute. Press molding; drying at 80-120°C for 12-36h; firing temperature at 1200-1400°C, holding time for 18-25h. That is, the high-purity cristobalite high-alkali-resistant low-the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com