Modified method for preparing single c-axle oriented zinc oxide film by electrochemical deposition process

A deposition process and electrochemical technology, which is applied in the preparation of ZnO thin films and single c-axis oriented ZnO thin films, can solve the problems of difficult to obtain dense ZnO thin films and control the nucleation density of thin films, and achieve strong single ultraviolet emission performance, Effect of high visible light transmittance, dense surface and cross-sectional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Prepare zinc nitrate precursor solution. 2.97 g of Zn(NO 3 ) 2 .6H 2 O was dissolved in 100 ml of deionized water to obtain a clear and transparent 0.1 mol / L zinc nitrate precursor solution.

[0051] 2. Use ITO glass as the substrate. Process as follows:

[0052] (1) Ultrasonic washing in detergent solution for 3-5 minutes, and then fully rinsed with deionized water;

[0053] (2) After taking it out, ultrasonically clean it in acetone and alcohol for 3-5 minutes, and then rinse it with deionized water;

[0054] (3) Immerse the cleaned ITO film in dilute hydrochloric acid with a concentration of 5% by volume and corrode it for 10 seconds, rinse thoroughly with deionized water after taking it out, and dry it for later use.

[0055] 3. Film growth. Divided into the following four steps:

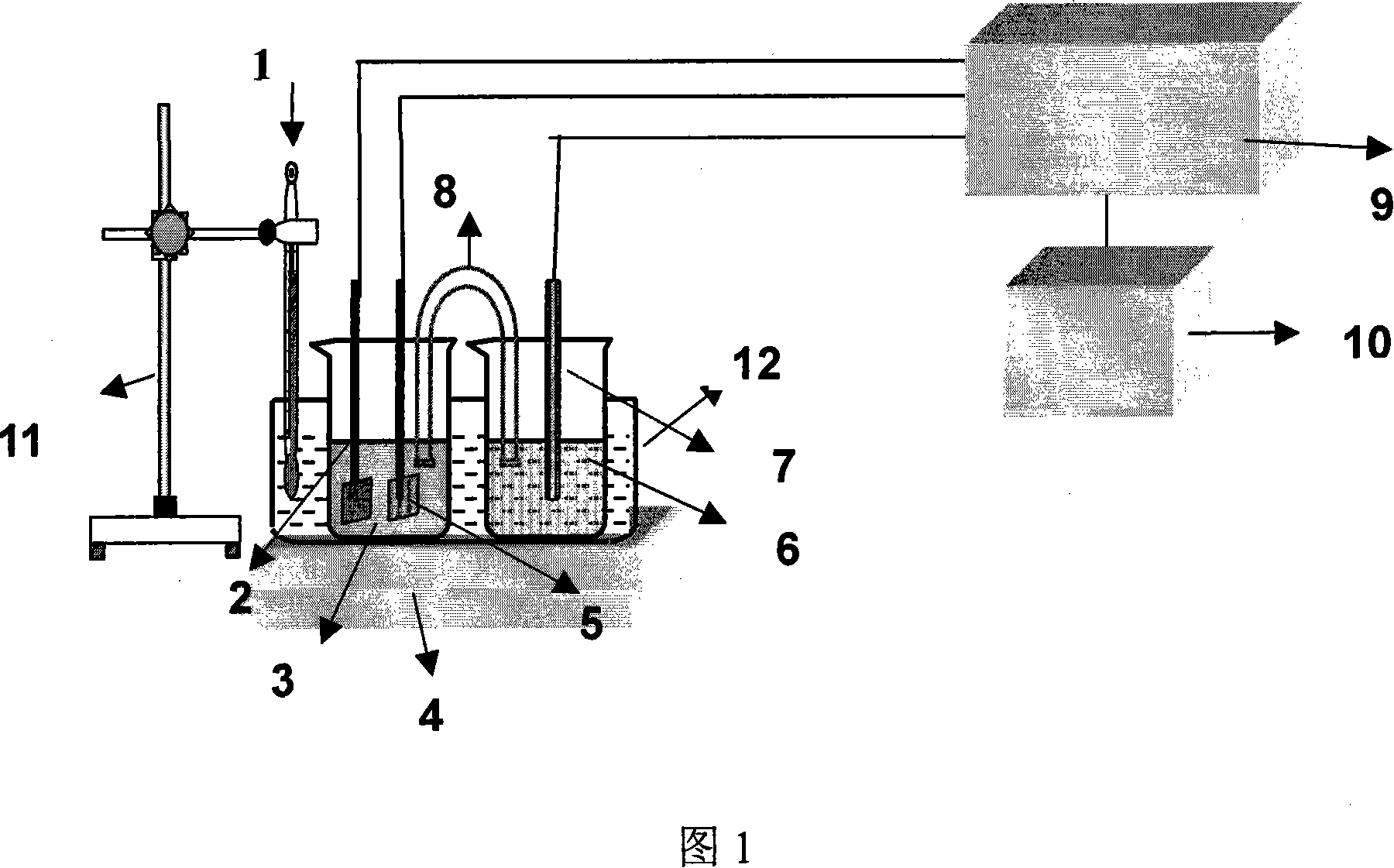

[0056] a. Connect the processed ITO substrate into the electrochemical deposition system as shown in Figure 1. The basic composition of the electrochemical deposition system i...

Embodiment 2

[0062] 1. Prepare zinc nitrate precursor solution. 0.297 g of Zn(NO 3 ) 2 .6H 2 O and 0.85 g NaNO 3 (sodium nitrate) was dissolved in 100 ml of deionized water to obtain a clear and transparent 0.1 mol / l zinc nitrate precursor solution, and the molar concentration ratio of zinc ions to nitrate ions was 1:11.

[0063] 2. Choose low-resistance single crystal silicon wafer as the substrate. Process as follows:

[0064] (1) At first, the hydrofluoric acid with a volume ratio of 1: 1 cleans the silicon chip under the condition of mechanical stirring for 5 minutes to remove the oxide layer on the surface of the silicon chip;

[0065] (2) After taking it out, ultrasonically clean it in acetone, alcohol, and deionized water for 5 minutes, then rinse it fully with deionized water after taking it out, and dry it for later use.

[0066] 3. Film growth. Divided into the following four steps:

[0067] a. Connect the processed substrate to the electrochemical deposition system, sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com