Control of crystal grain size of polysilicon film and detecting method thereof

A polysilicon thin film, grain size technology, applied in measurement devices, semiconductor/solid-state device testing/measurement, material analysis by optical means, etc., can solve the problem of inability to accurately obtain laser energy density and crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

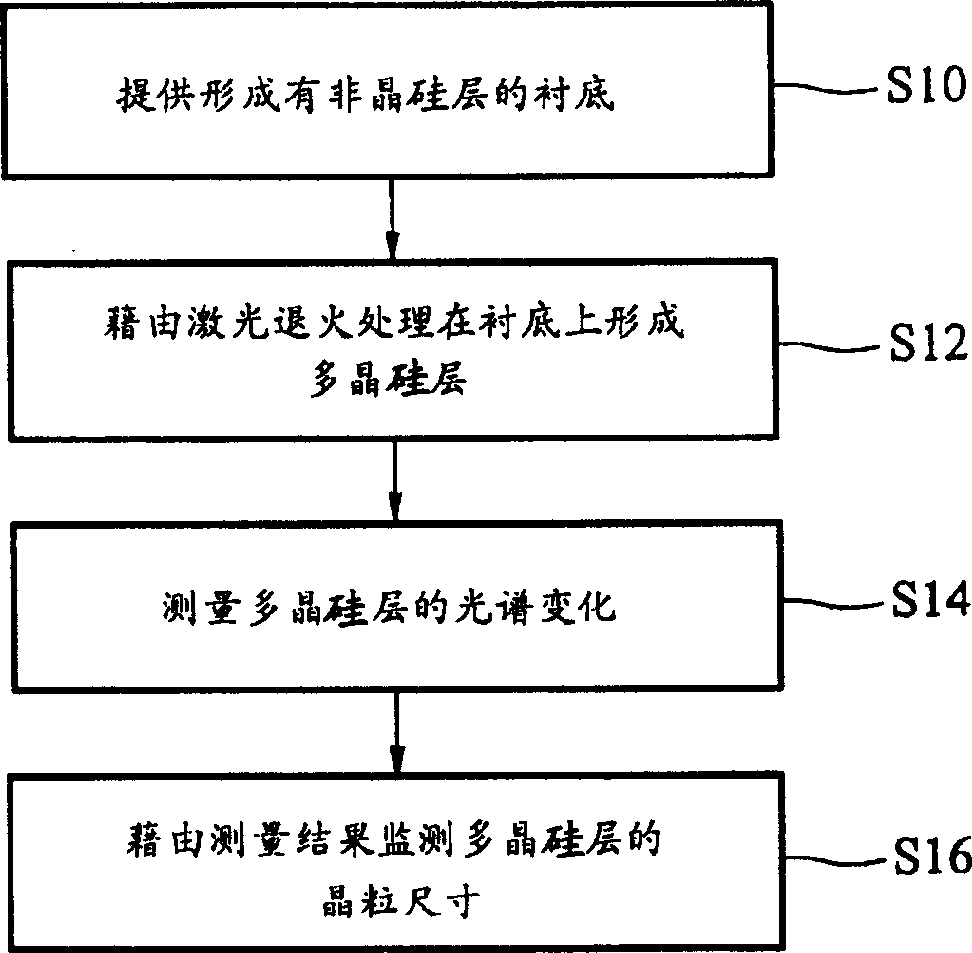

[0023] figure 1 is a flow chart illustrating a polysilicon thin film detection method according to an embodiment of the present invention. First, step S10 is performed to provide a substrate, such as a transparent glass substrate, on which an amorphous silicon (α-Si) layer is formed. In this embodiment, this substrate is used to fabricate a thin film transistor liquid crystal display (TFT-LCD). The amorphous silicon layer on the substrate is used for subsequent fabrication of the channel layer of the thin film transistor. The amorphous silicon layer can be formed by chemical vapor deposition (CVD) or other methods, and its thickness is in the range of about 300 to 1000 angstroms (Å).

[0024] Next, step S12 is performed to anneal the amorphous silicon layer with a laser with a predetermined energy density, such as excimer laser annealing (ELA), to convert the amorphous silicon layer into a polysilicon (p-Si) layer . In this embodiment, the predetermined energy density of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com