Method for preparing polycrystalline textured thermoelectric material from single-crystal bismuth sulfide precursor powder

A technology of thermoelectric materials and precursor powders, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of limited maximum texture degree, large grain size of textured samples, and insignificant texture phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

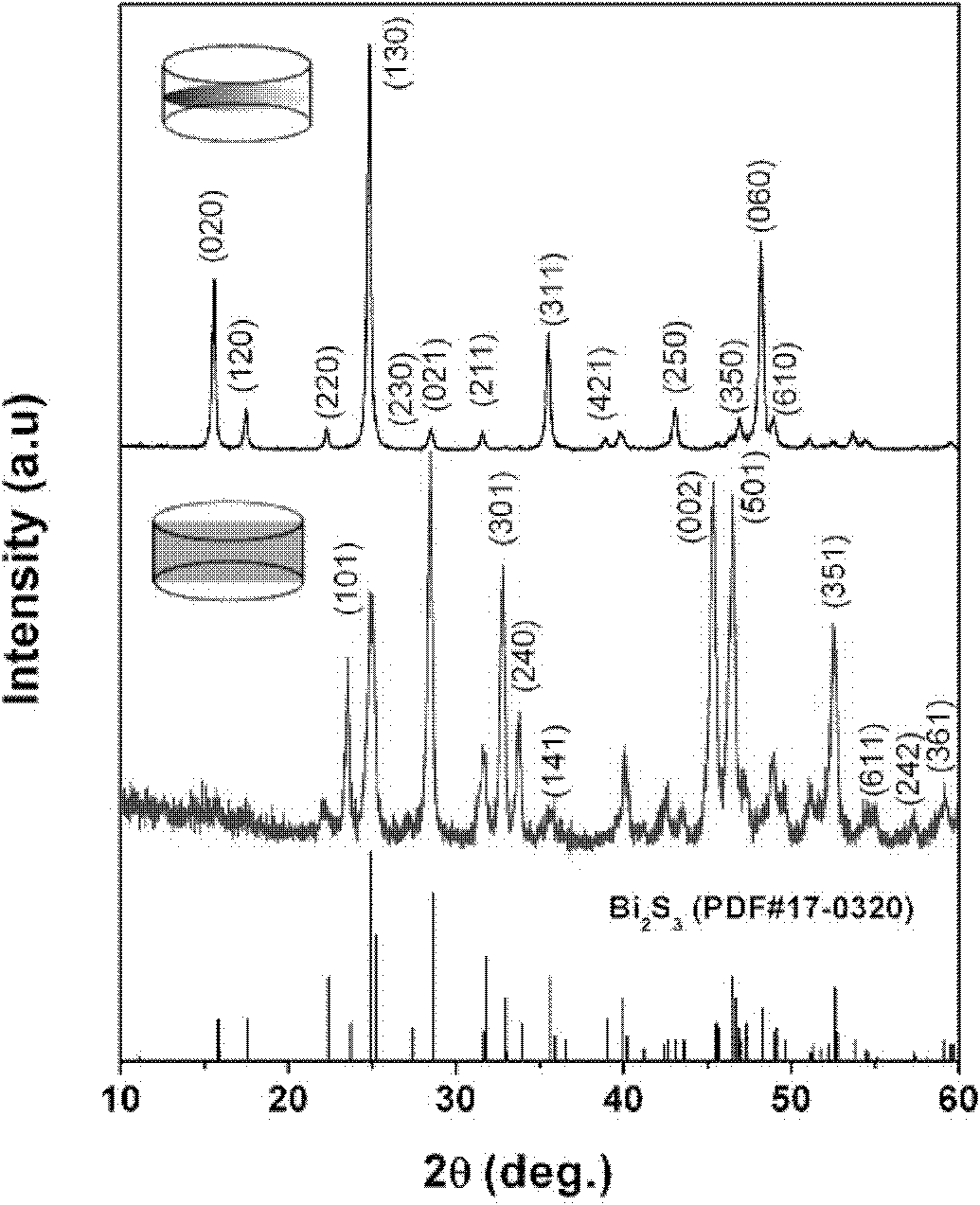

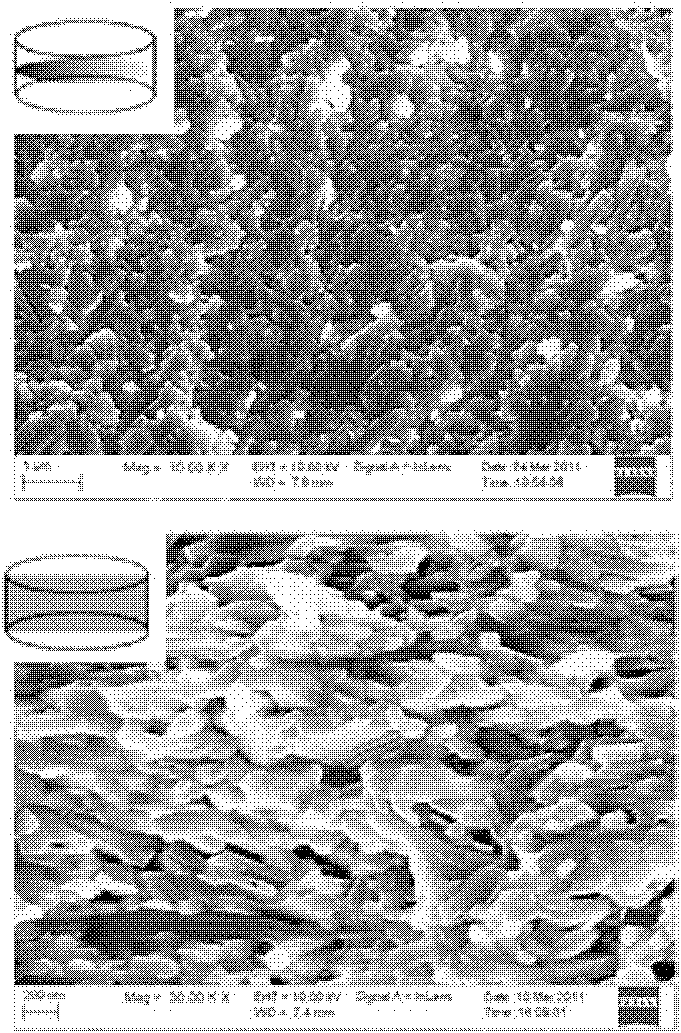

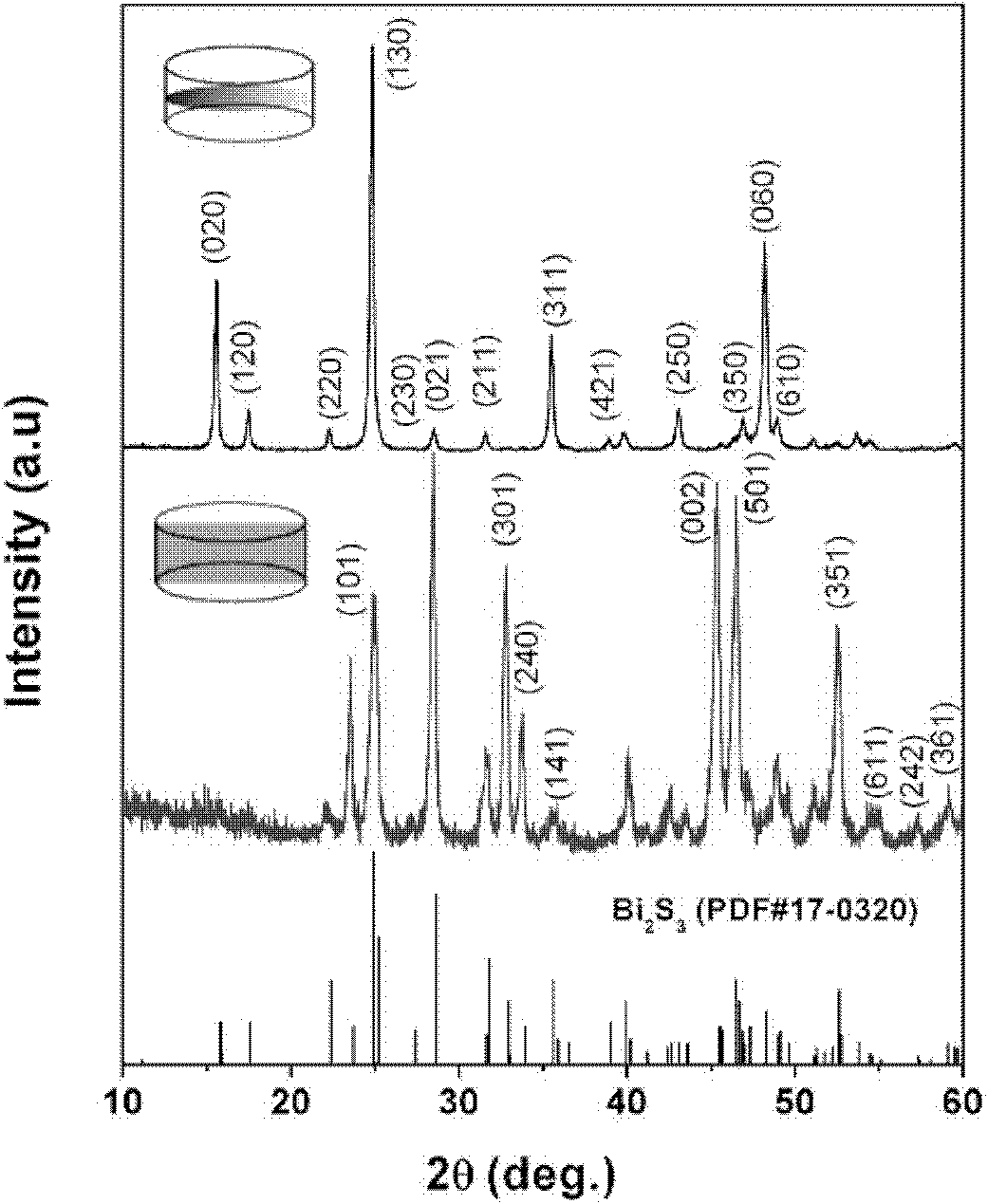

example 1

[0017] (0 0 l)-oriented single crystal Bi 2 S 3 The nanosheet powder was ultrasonically dispersed in alcohol for 10 min, dried and ground in an agate mortar for 30 min as a precursor powder. The precursor powder was placed in a graphite mold with a diameter of 10 mm, and the mold was placed in a spark plasma sintering furnace, the pressure was maintained at 40 MPa, the sintering temperature was 773 K, and the heat preservation time was 0 min to obtain a dense polycrystalline block with high texture thermoelectric materials. According to the XRD test and quantitative calculation, the texture degree of the (h k 0) plane is F=0.79, and the thermoelectric performance test results show that it has good temperature stability, and the power factor is 200~220 μWm in the test range from room temperature to 300 °C -1 K -2 .

example 2

[0019] (0 0 l)-oriented single crystal Bi 2 S 2.75 The nanotube powder was ultrasonically dispersed in alcohol for 30 min, dried and ground in an agate mortar for 60 min as a precursor powder. The precursor powder was placed in a graphite mold with a diameter of 15 mm, and the mold was placed in a spark plasma sintering furnace, the pressure was maintained at 80 MPa, the sintering temperature was 673 K, and the temperature was kept for 3 minutes to obtain a dense polycrystalline block with high texture thermoelectric materials. According to the XRD test and quantitative calculation, the texture degree of the (h k 0) plane is F=0.91, and the thermoelectric performance test results show that it has good temperature stability, and the power factor is 250~300 μWm in the test range from room temperature to 300 °C -1 K -2 .

example 3

[0021] (0 0 l)-oriented single crystal Bi 2 S 2.8 The nanowire powder was ultrasonically dispersed in alcohol for 10 min, dried and ground in an agate mortar for 10 min as a precursor powder. The precursor powder was placed in a graphite mold with a diameter of 20 mm, and then the mold was placed in a spark plasma sintering furnace, the pressure was maintained at 20 MPa, the sintering temperature was 573 K, and the sintering temperature was 573 K for 5 minutes to obtain a dense polycrystalline block with high texture Bulk thermoelectric materials. According to XRD test and quantitative calculation, the texture degree of (h k 0) plane is F=0.69, and the thermoelectric performance test results show that it has good temperature stability, and the power factor is 80~90 μWm in the test range from room temperature to 300 °C -1 K -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com