Cold crack pouring asphalt emulsion and preparation method thereof

An asphalt emulsion and cold irrigation technology, which is applied to building components, pavement details, building insulation materials, etc., can solve the problems that the surface of asphalt emulsion cannot be rapidly solidified, the asphalt emulsion does not freeze, and does not deform for a long time, and achieves low cost and penetration. And the effect of good adhesion and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

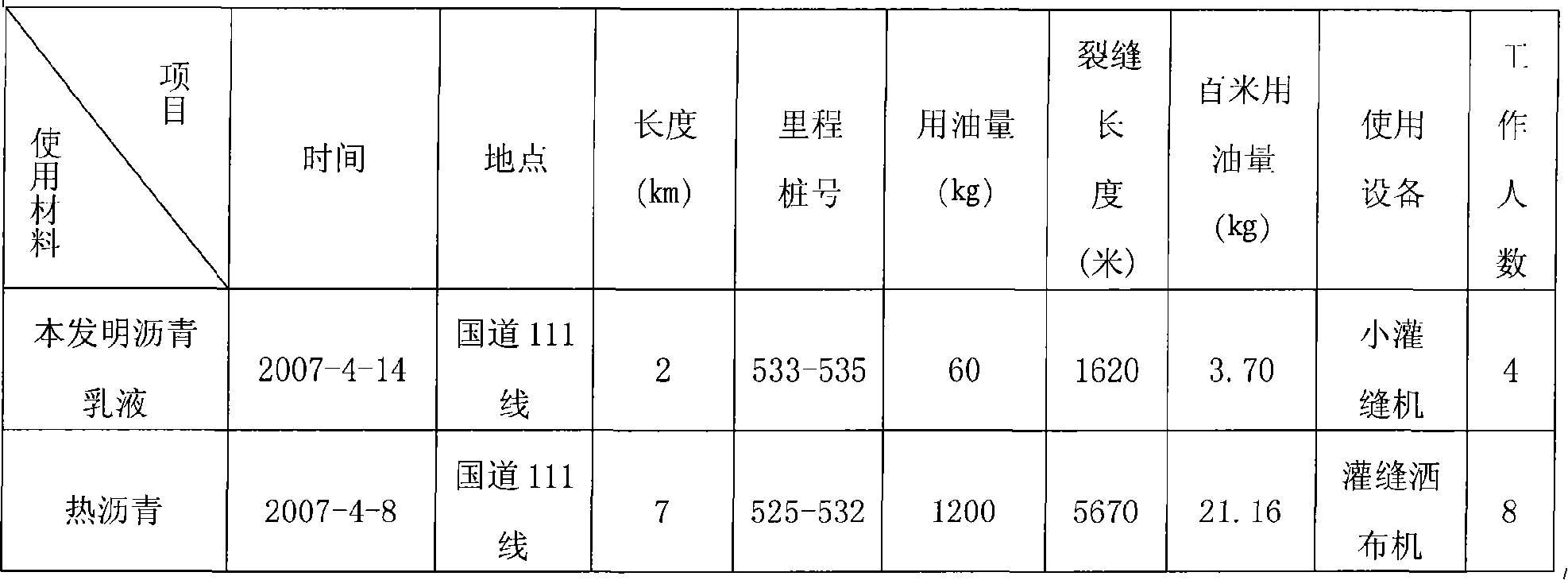

[0049] Example 1: 50 parts of asphalt, 3 parts of solvent oil, 4 parts of vegetable oil, 1 part of anionic asphalt emulsifier, 8 parts of ethylene glycol, and 24 parts of water.

Embodiment 2

[0050] Example 2: 56 parts of asphalt, 4 parts of solvent oil, 3 parts of vegetable oil, 2 parts of anionic asphalt emulsifier, 9 parts of glycerin, and 22 parts of water.

Embodiment 3

[0051] Example 3: 60 parts of asphalt, 5 parts of solvent oil, 5 parts of vegetable oil, 2 parts of cationic asphalt emulsifier, 10 parts of ethylene glycol, and 30 parts of water.

[0052] The preparation method of the emulsion of the present invention is made up of the following steps:

[0053] A. Put the asphalt in the container and heat it to 120℃

[0054] B. Mix the vegetable oil and solvent oil together, after stirring evenly, pour it into the hot asphalt in stages and quickly stir it evenly;

[0055] C. Add ethylene glycol into water, stir evenly and heat to 55°C;

[0056] D. Pour the asphalt bitumen emulsifier into the water at 55°C, and stir it evenly to form an emulsion;

[0057] E. The blended asphalt and the blended emulsion are processed through the gear pump, the flow meter, and the grease homogenizer respectively. The processed product is the cold-filling asphalt emulsion.

[0058] Anionic or cationic asphalt emulsifier is produced by Shandong Boxing Runda Ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com