Method and device for vacuum filling cracks in pavement

A technology for pavement cracks and vacuum, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of damage and poor filling effect, and achieve the effect of avoiding secondary damage, full and dense filling joints, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

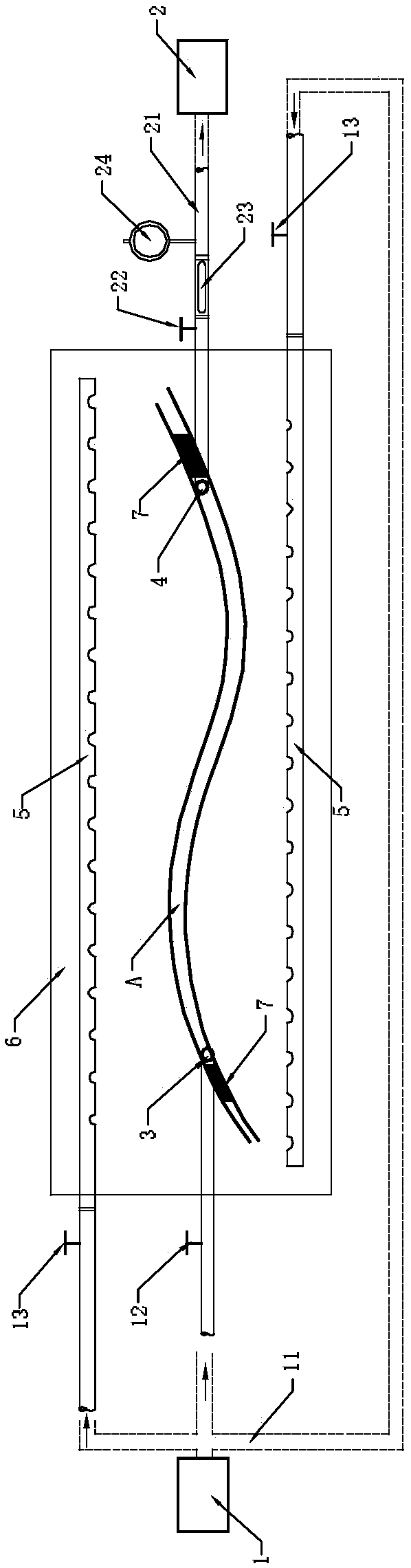

[0031] A vacuum joint filling device for pavement cracks, comprising a joint filling machine 1, a vacuum pump 2, a glue filling nozzle 3, a vacuum nozzle 4, a vacuum pad 6, and two pore-blocking pipes 5.

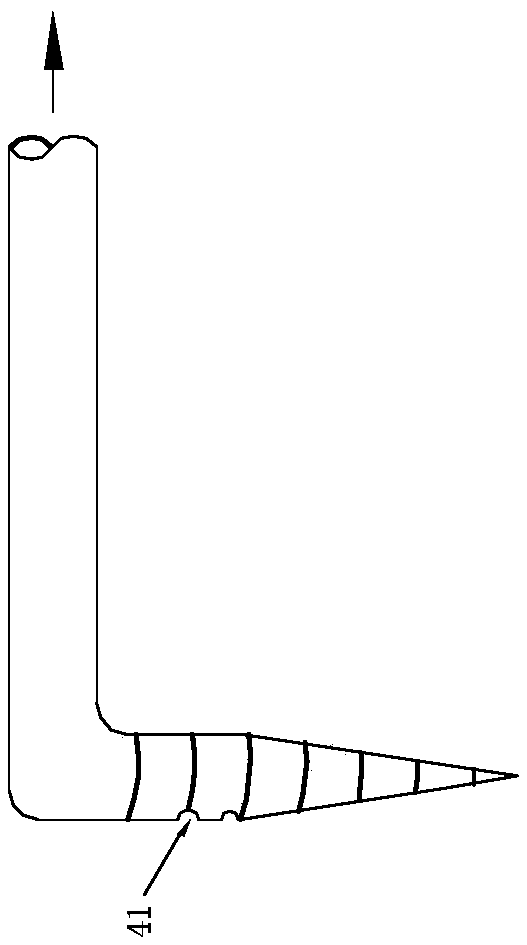

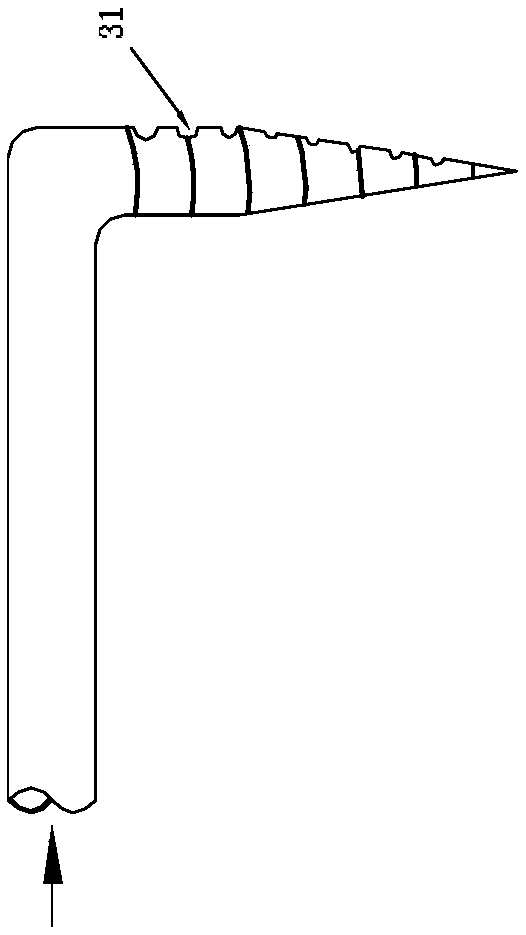

[0032] The glue filling nozzle is connected to the seam filling machine through the glue filling pipe 11. The front end of the glue filling nozzle is provided with a glue outlet head bent at 90 degrees. The glue outlet head is conical and is provided with a glue outlet 31 and a screw thread. The glue outlet is located on the outside of the glue head ( image 3 to the right of the ). The vacuum nozzle is connected to the vacuum pump through a vacuum tube 21. The front end of the vacuum nozzle is provided with a suction head bent at 90 degrees. The suction head is conical and the suction head is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com