Self-flow hard grouting material and using method thereof

A grouting material and quick-hardening technology, applied in the field of Portland cement, can solve the problems of unsatisfactory strength index, long drying and hardening time, prolonged working time, etc., and achieve high fluidity, high mechanical strength, and setting speed quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of self-flowing hard grouting material, which is composed of cement, expansion agent, coagulation regulator, retarder, water reducer, sand, defoamer and crushed stone. It is characterized in that: the mass parts of each component are as follows Shown:

[0027] components

parts by mass

cement

0.5

expansion agent

0.05

Coagulant

0.2

retarder

0.004

0.01

sand

0.6

0.001

gravel

0.7

[0028] Among them: calcium sulfoaluminate is used as the expansion agent, gypsum is used as the coagulation agent, sodium gluconate is used as the retarder, naphthalenesulfonate formaldehyde condensate is used as the water reducer, and simethicone mixed with SiO is used as the defoamer. 2 The compound composed of aerosol, the particle size distribution of gravel is 5mm~10mm.

[0029] When this embodiment is used, it should be cleaned first to remov...

Embodiment 2

[0036] A kind of self-flowing hard grouting material, which is composed of cement, expansion agent, coagulation regulator, retarder, water reducer, sand, defoamer and crushed stone. It is characterized in that: the mass parts of each component are as follows Shown:

[0037] components

[0038] Others are all the same with embodiment 1.

Embodiment 3

[0040] A kind of self-flowing hard grouting material, which is composed of cement, expansion agent, coagulation regulator, retarder, water reducer, sand, defoamer and crushed stone. It is characterized in that: the mass parts of each component are as follows Shown:

[0041] components

parts by mass

cement

1.00

expansion agent

0.11

Coagulant

0.25

[0042] retarder

0.0049

0.017

sand

0.66

0.0014

gravel

0.86

[0043] Others are all the same with embodiment 1.

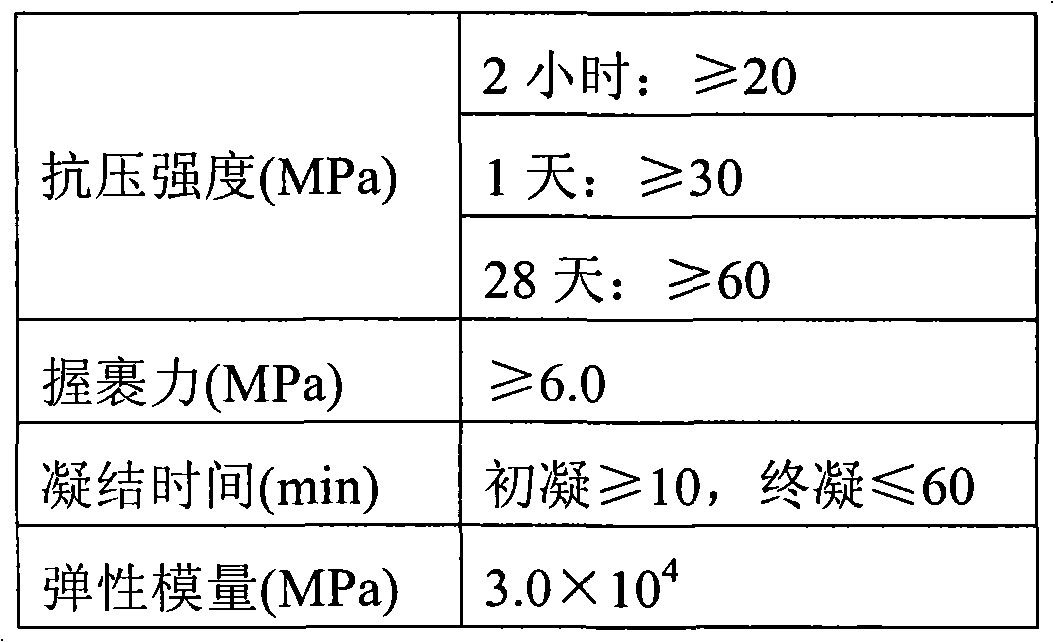

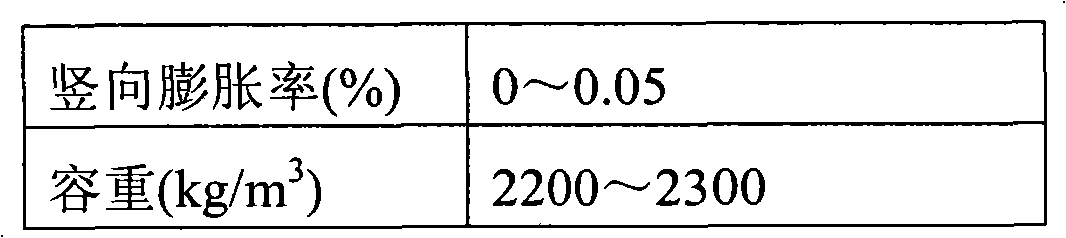

[0044] The performance index of this embodiment is:

[0045]

[0046]

[0047] This embodiment has the following characteristics:

[0048] Self-flow and vibration-free: self-flow, construction vibration-free, to ensure no leakage grouting;

[0049] Rapid hardening and early strength: the strength can reach 20MPa 2 hours after pouring, and the highest strength can re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com