Preparation method of superhydrophobic melamine sponge modified by utilizing dopamine and carbon nanotubes

A technology of carbon nanotube modification and melamine sponge, which is applied in the field of preparation of superhydrophobic melamine sponge, can solve the problems of high cost, complicated preparation process, and improvement of adsorption selectivity, and achieve mild reaction conditions and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

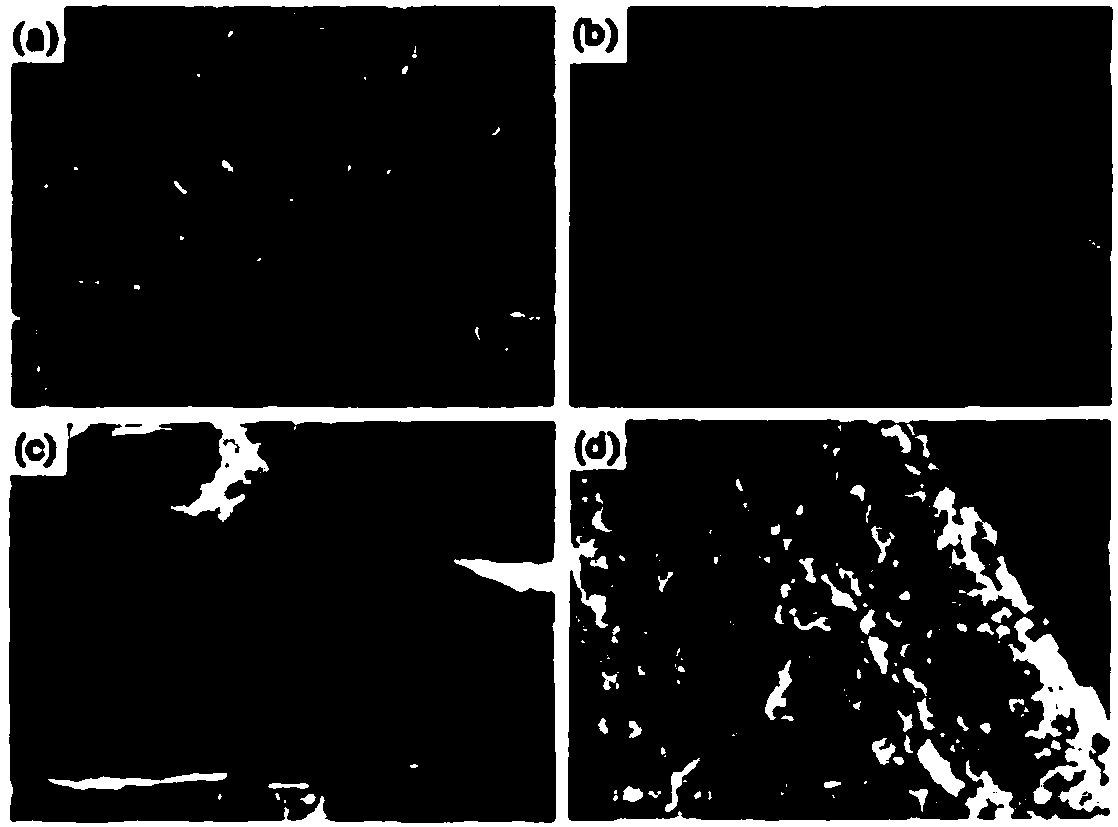

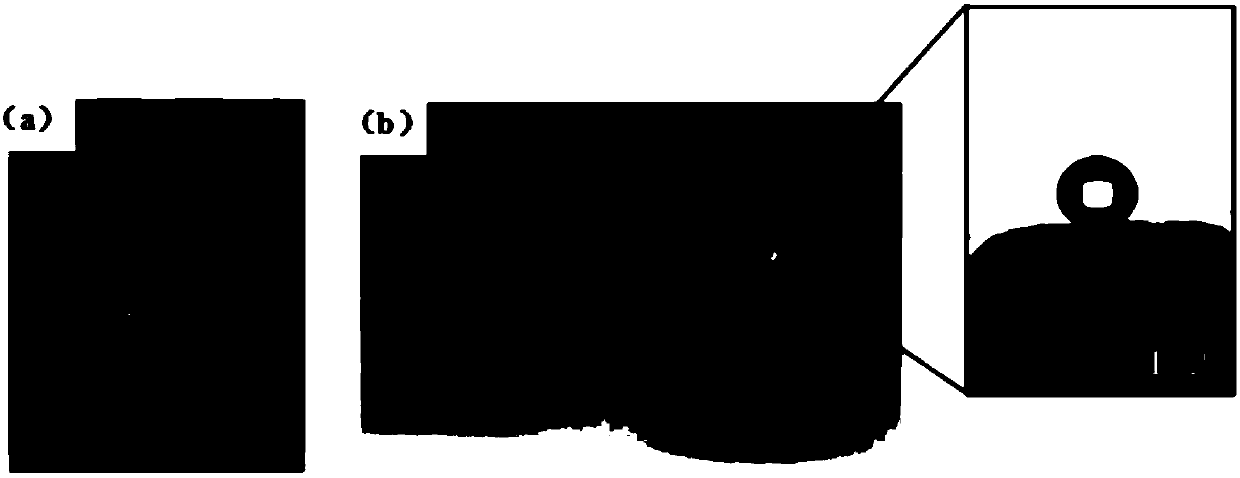

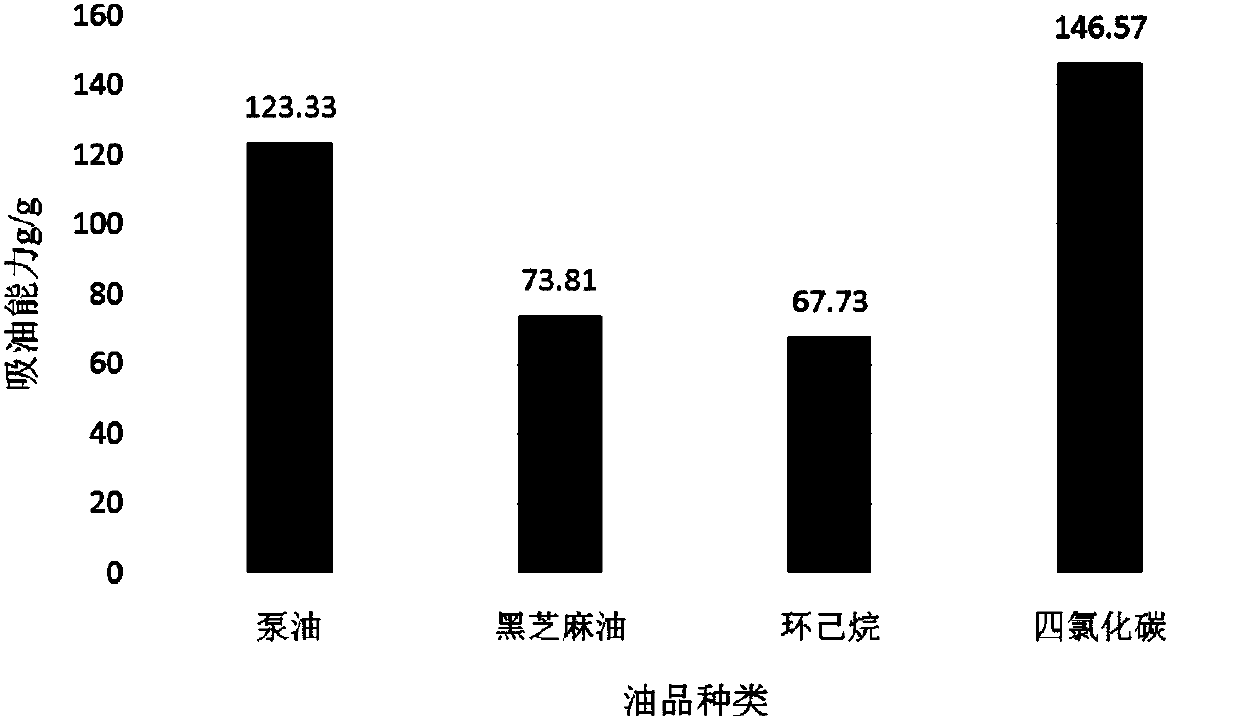

[0033] According to the mass ratio of dopamine hydrochloride and Tris is 0.79, and the dopamine hydrochloride concentration added is the ratio of 2g / L to prepare two parts of dopamine solutions of the same composition, then add a few drops of concentrated hydrochloric acid with a mass fraction of 36.5% to adjust the pH of the solution, so that It falls between 7-8. According to the mass ratio of carbon nanotubes to dopamine hydrochloride used in the preparation of dopamine solution of 1:2, carbon nanotubes were added to one part of the dopamine solution, stirred briefly and ultrasonically dispersed at 45°C for 30min, then magnetically dispersed at 20°C. Stir for 24h. The resulting black solution was filtered and washed with a large amount of distilled water, and the carbon nanotubes on the microfiltration membrane were collected and vacuum-dried at 50° C. to obtain CNTs-PDA. The purchased melamine sponge (1cm×1cm×1cm) was soaked in ammonia water / ethanol solution (the volume r...

Embodiment 2

[0036] According to the mass ratio of dopamine hydrochloride and Tris is 0.83, and the concentration of added dopamine hydrochloride is the ratio of 2g / L to prepare two parts of dopamine solutions of the same composition, then drop a few drops of concentrated hydrochloric acid with a mass fraction of 36.5% to adjust the pH of the solution, Make it fall between 7-8. According to the mass ratio of carbon nanotubes to dopamine hydrochloride 1:2, carbon nanotubes were added to one part of the dopamine solution, stirred briefly and ultrasonically dispersed at 45°C for 60min, followed by magnetic stirring at 20°C for 24h. The resulting black solution was filtered and washed with a large amount of distilled water, and the carbon nanotubes on the microfiltration membrane were collected and vacuum-dried at 60°C to obtain CNTs-PDA. Soak the purchased melamine sponge (1cm×1cm×1cm) in ammonia water / ethanol solution (the volume ratio of ammonia water to ethanol is 1:1), ultrasonically clea...

Embodiment 3

[0040] According to the mass ratio of dopamine hydrochloride and Tris is 0.91, and the concentration of added dopamine hydrochloride is the ratio of 2g / L to prepare two parts of dopamine solutions of the same composition, then add a few drops of concentrated hydrochloric acid with a mass fraction of 36.5% to adjust the pH of the solution, Make it fall between 7-8. According to the mass ratio of carbon nanotubes to dopamine hydrochloride 1:2, carbon nanotubes were added to one part of the dopamine solution, stirred briefly, ultrasonically dispersed at 50°C for 30min, and then magnetically stirred at 25°C for 24h. The resulting black solution was filtered and washed with a large amount of distilled water, and the carbon nanotubes on the microfiltration membrane were collected and dried in vacuum at 45°C to obtain CNTs-PDA. Soak the purchased melamine sponge (1cm×1cm×1cm) in ammonia water / ethanol solution (the volume ratio of ammonia water to ethanol is 1:1), ultrasonically clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorptive capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com