Method for preparing high grade edible fiber using apple slag as raw material and fruit juice enriched with said edible cellulose

A technology of dietary fiber and apple pomace, which is applied in the field of highly refined dietary fiber, fruit juice drinks or food, can solve the problems of lignin destruction, high production cost, environmental pollution, etc., achieve high water holding rate and oil holding rate, and improve health care function, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

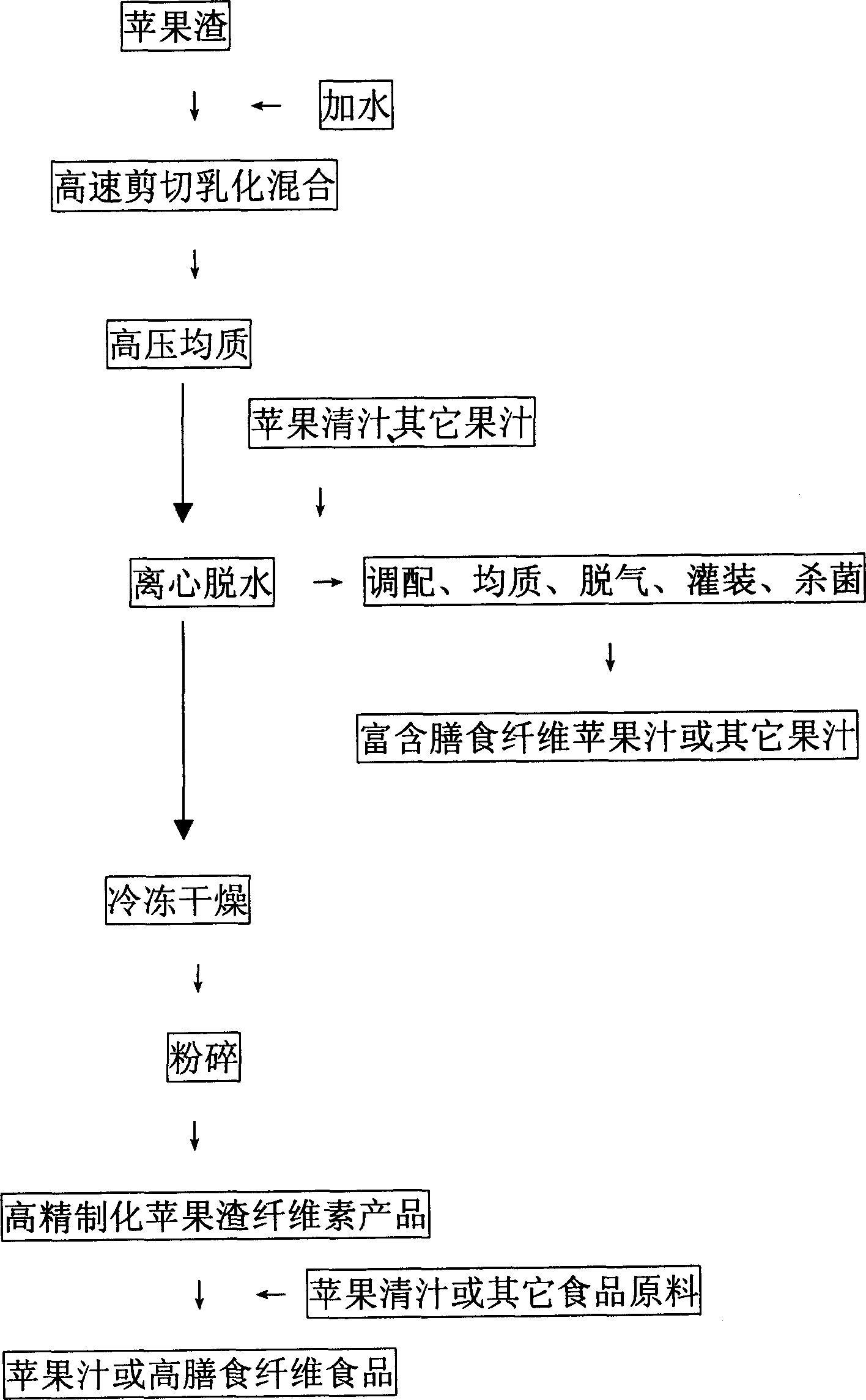

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Take 5Kg of dried apple pomace and add 250Kg of water to mix, put it into a high-speed shear emulsifier, and process it at 6500 rpm for 20 minutes to obtain an intermediate treatment solution with a fiber length of 0.1-5 microns. The above-mentioned treatment liquid was homogenized three times under the condition of pressurizing to 550 bar with an ultra-high pressure homogenizer, dehydrated at 2000 rpm to a moisture content of 70%, and then freeze-dried at a low temperature of -15 degrees Celsius to a moisture content of 3% and crushed into 130 Mesh powder. A 4.8Kg highly refined apple pomace dietary fiber product can be obtained. The yield is 96%.

Embodiment 2

[0022] Example 2 Take 50Kg of fresh apple pomace and mix with 300Kg of water, put it into a high-shear mixing emulsifier, process it for 15 minutes under the condition of 8500 rpm, pressurize the obtained solution to 450bar with an ultra-high pressure homogenizer, and homogenize it 3 times at the same time Perform secondary crushing to obtain products with a particle size of 0.01-2 microns; dehydrate to a moisture content of 75% by centrifugation at 2000 rpm, and freeze-dry in a freeze dryer at minus 20 degrees Celsius to a moisture content of 5% And be crushed into 150 order powder, obtain 9.4Kg highly refined apple pomace dietary fiber product, yield 94% (according to dry apple pomace).

Embodiment 3

[0023] Embodiment 3 Get the highly refined apple pomace dietary fiber product gained in 2Kg embodiment 1 and mix with 100Kg apple clear juice, homogenize under 200bar pressure condition 3 times so that dietary fiber is fully and evenly dispersed, degassing, filling and ultraviolet disinfection, to obtain 102Kg apple juice product rich in dietary fiber of highly refined apple pomace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com