Enteromorpha gel oil suction material and preparation method thereof

A technology of oil-absorbing material and enteromorpha, which is applied in the field of enteromorpha gel oil-absorbing material and its preparation, can solve problems such as secondary pollution, and achieve the effects of improving utilization rate, large oil absorption ratio, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

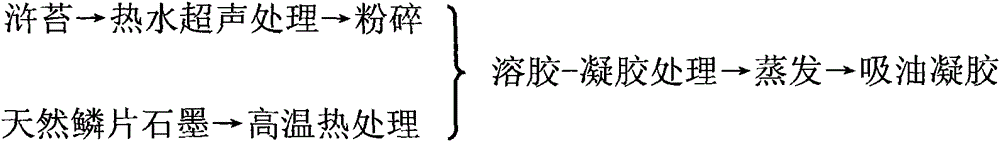

Image

Examples

Embodiment 1

[0032]Extraction of active substances of Enteromorpha: Cut Enteromorpha fibers into main fiber length <10mm, soak in hot water at 40-60°C to remove sediment. Enteromorpha fibers are placed in an ultrasonic generator with a pH value of 5-6, a solid-liquid ratio of 1:35-40, an ultrasonic power of 1000W, a frequency of 28kHz, and extraction at 40-60°C for 25 minutes. A mixed solution of n-butanol and chloroform (n-butanol: chloroform = 1:4-5) was mixed with Enteromorpha extract and shaken thoroughly for 30 min. Using centrifuge to centrifuge, the final extract includes sugar alcohol, fatty acid and crude fiber.

[0033] Gel material formula: Enteromorpha extract 60%, expanded graphite 15%, iron nitrate 4%, cobalt nitrate 8%, citric acid 8%, ammonia water 4%.

[0034] Sol-gel treatment process: Ferric nitrate, cobalt nitrate and citric acid are completely dissolved in the reaction kettle at a ratio of 1:2:2, and ammonia water is added to keep the pH of the solution between 7.0 an...

Embodiment 2

[0037] Extraction of active substances of Enteromorpha: Cut Enteromorpha fibers into main fiber length <10mm, soak in hot water at 40-60°C to remove sediment. Then transfer to an ultrasonic generator, the pH value is 5-6, the solid-liquid ratio is 1:35-40, the ultrasonic power is 1000W, the frequency is 28kHz, and extraction is carried out at 40-60°C for 25min. A mixed solution of n-butanol and chloroform (n-butanol: chloroform = 1:4-5) was mixed with Enteromorpha extract and shaken thoroughly for 30 min. Using centrifuge to centrifuge, the final extract includes sugar alcohol, fatty acid and crude fiber.

[0038] Gel material formula: Enteromorpha extract 65%, expanded graphite 13%, iron nitrate 3%, cobalt nitrate 6%, citric acid 9%, ammonia water 4%.

[0039] Sol-gel treatment process: Ferric nitrate, cobalt nitrate and citric acid are completely dissolved in the reaction kettle at a ratio of 1:2:3, and ammonia water is added to keep the pH of the solution between 7.0 and 8...

Embodiment 3

[0042] Extraction of active substances of Enteromorpha: Cut Enteromorpha fibers into main fiber length <10mm, soak in hot water at 40-60°C to remove sediment. Then transfer to an ultrasonic generator, the pH value is 5-6, the solid-liquid ratio is 1:35-40, the ultrasonic power is 1000W, the frequency is 28kHz, and extraction is carried out at 40-60°C for 25min. A mixed solution of n-butanol and chloroform (n-butanol: chloroform = 1:4-5) was mixed with Enteromorpha extract and shaken thoroughly for 30 min. Using centrifuge to centrifuge, the final extract includes sugar alcohol, fatty acid and crude fiber.

[0043] Gel material formula: Enteromorpha extract 70%, expanded graphite 5%, iron nitrate 3%, cobalt nitrate 6%, citric acid 12%, ammonia water 4%.

[0044] Sol-gel treatment process: Ferric nitrate, cobalt nitrate and citric acid are completely dissolved in the reaction kettle at a ratio of 1:2:4, and ammonia water is added to keep the pH of the solution between 7.0 and 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com