Material of porous polyimide holder and molding technique

A technology of polyimide and pure polyimide, which is applied in the field of bearing cages, can solve problems such as low strength, short life, and low reliability, and achieve the effects of increased strength, improved machining performance, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

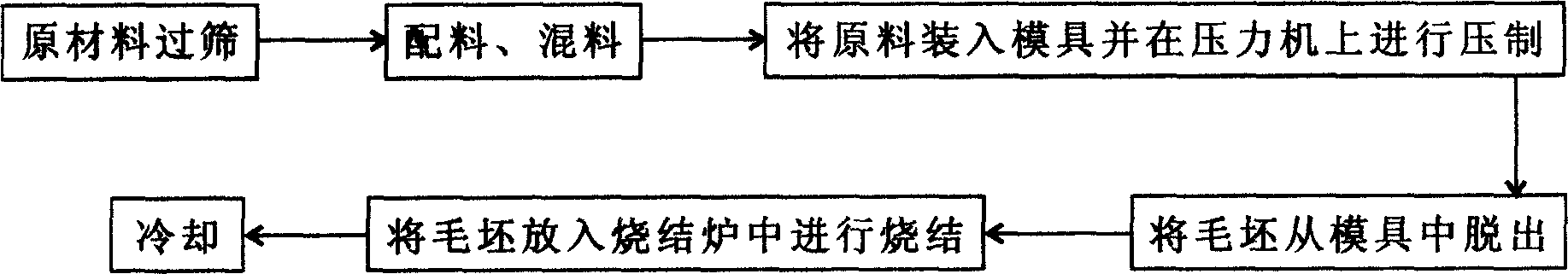

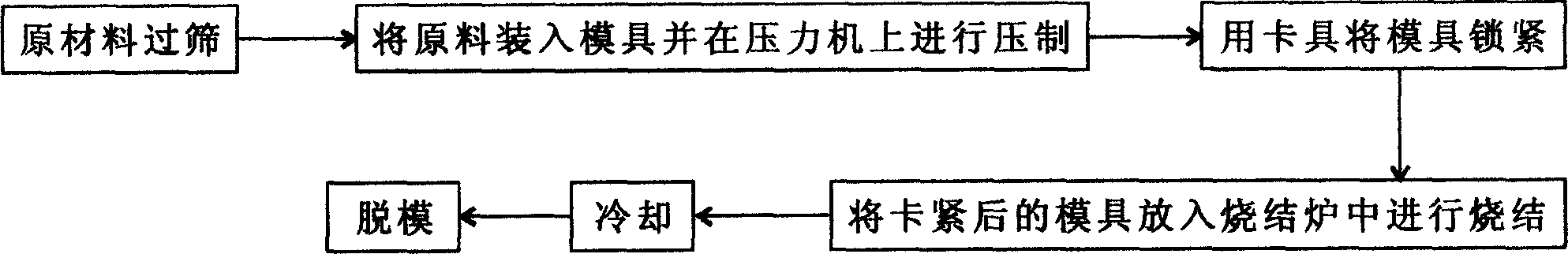

[0023] The specific implementation of the molding process for preparing the newly developed porous polyimide cage material is:

[0024] Sieve the pure polyimide material to make the polyimide powder reach a particle size of 80-300 mesh; put it into a mold and press it, and the molding pressure is: 2kN / cm 2 ~8kN / cm 2 ; Lock the mold, the locking force is: 100N ~ 500N; sintering in the sintering furnace, the sintering temperature: 370 ℃ ~ 390 ℃; heat preservation, heat preservation time: 5 ~ 40 minutes; finally cooling, demoulding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com