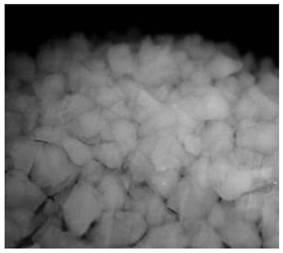

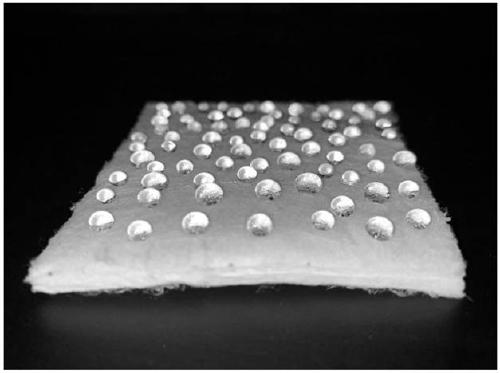

SiO2 aerogel modified polypropylene melt-blown nonwoven material and preparation method thereof

A non-woven material, polypropylene melt-blown technology, applied in non-woven fabrics, single-component polyolefin rayon, melt spinning and other directions, can solve problems such as the oil absorption ratio to be improved, and achieve low production cost and simple process. , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of silica airgel modified polypropylene melt-blown nonwoven material, the steps are as follows:

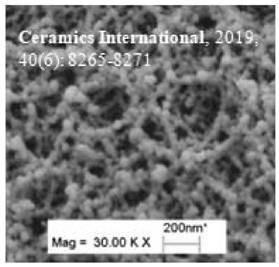

[0035] (1) Hydrophobic SiO 2 Preparation of airgel

[0036] Add 52ml of tetraethylorthosilicate, 221ml of absolute ethanol, and 13ml of deionized water into the beaker, and adjust the pH value to 3 with a hydrochloric acid ethanol solution with a concentration of 1mol / L. After stirring for 50 minutes, add ammonia water ethanol solution with a volume ratio of 1:20 to adjust the pH of the solution to 6, and then stir for 20 minutes to obtain SiO 2 Sol. Gel at room temperature. After gelling, the SiO 2 The wet gel was soaked in absolute ethanol, aged at room temperature for 2 days, and the aged SiO 2 The wet gel was soaked in hexamethyldisilazane for 2d for surface modification. After surface modification, the SiO 2 The wet gel was soaked in absolute ethanol and aged at room temperature for 2 days. The aged composite was subjected to CO 2 Supercri...

Embodiment 1

[0051] A preparation method of silica airgel modified polypropylene melt-blown nonwoven material, the steps are as follows

[0052] (1) Add 52ml of tetraethylorthosilicate, 221ml of absolute ethanol, and 13ml of deionized water into a beaker, and adjust the pH value to 3 with a hydrochloric acid ethanol solution with a concentration of 1mol / l. After stirring for 50 minutes, add ammonia water ethanol solution with a volume ratio of 1:20 to adjust the pH of the solution to 6, and then stir for 20 minutes to obtain SiO 2 Sol. Gel at room temperature. After gelling, the SiO 2 The wet gel was soaked in absolute ethanol, aged at room temperature for 2 days, and the aged SiO 2 The wet gel was soaked in hexamethyldisilazane for 2d for surface modification. After surface modification, the SiO 2 The wet gel was soaked in absolute ethanol and aged at room temperature for 2 days. The aged composite was subjected to CO 2 Supercritical drying treatment to obtain hydrophobic SiO 2 Ai...

Embodiment 2

[0057] A preparation method of silica airgel modified polypropylene melt-blown nonwoven material, the steps are as follows:

[0058] (1) Add 52ml of tetraethylorthosilicate, 221ml of absolute ethanol, and 13ml of deionized water into a beaker, and adjust the pH value to 3 with a hydrochloric acid ethanol solution with a concentration of 1mol / l. After stirring for 50 minutes, add ammonia water ethanol solution with a volume ratio of 1:20 to adjust the pH of the solution to 6, and then stir for 20 minutes to obtain SiO 2 Sol. Gel at room temperature. After gelling, the SiO 2 The wet gel was soaked in absolute ethanol, aged at room temperature for 2 days, and the aged SiO 2 The wet gel was soaked in hexamethyldisilazane for 2d for surface modification. After surface modification, the SiO 2 The wet gel was soaked in absolute ethanol and aged at room temperature for 2 days. The aged composite was subjected to CO 2 Supercritical drying treatment to obtain hydrophobic SiO 2 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com