Method for extracting peanut oil and fat and protein with ultrasonic assisted aqueous enzymatic method

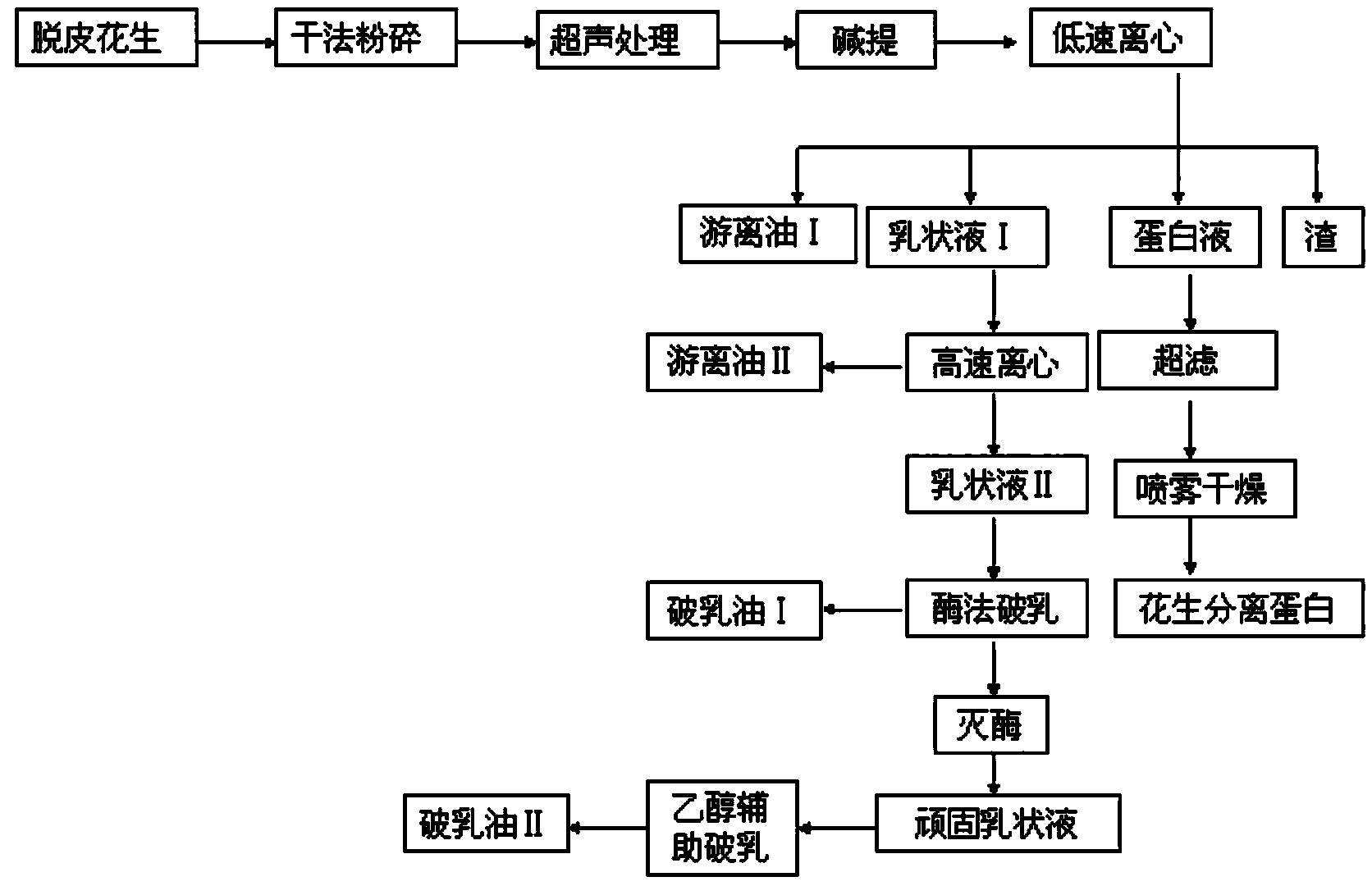

An ultrasound-assisted and hydroenzymatic technology, which is applied to peptide preparation methods, chemical instruments and methods, and fat production, can solve the problems of low extraction rate of free oil, high residual oil rate of emulsion, and insufficient comprehensive utilization of protein. Achieve the effects of promoting comprehensive utilization, reducing energy and resource consumption, and reducing the amount of enzymes used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Screen the peeled peanuts to remove impurities, dry crush until the average particle size of peanuts is about 38 μm, dissolve the crushed peanut pulp and water at a ratio of 1:5 (w / v) to liquid, adjust the pH of the system with 1M NaOH After reaching 9.00, use a 400W ultrasonic wave for 3 minutes, then adjust the pH to 9.00, extract in a water bath at 60°C for 4 hours, centrifuge at 3000 rpm for 20 minutes, and divide into four layers, which are free oil Ⅰ, emulsion Ⅰ, protein liquid and slag , Weigh the mass of free oil Ⅰ. After the protein solution was diluted, a membrane with a molecular weight cut-off of 10k was selected for ultrafiltration, and the retentate was spray-dried at an inlet temperature of 170°C and an outlet temperature of 80°C. Emulsion I was centrifuged at 8000 rpm for 20 minutes to obtain free oil II, which was weighed. The remaining emulsion liquid phase was broken by enzymatic method, the conditions were: papain / phospholipase (2:1, w / w), temperatu...

Embodiment 2

[0040]Screen the peeled peanuts to remove impurities, dry crush until the average particle size of peanuts is about 40 μm, dissolve the crushed peanut pulp and water at a ratio of 1:4 (w / v) to liquid, and adjust the pH of the system with 1M NaOH to 8.50, then use a 450W ultrasonic wave for 4 minutes, then adjust the pH back to 8.50, extract in a water bath at 60°C for 5 hours, centrifuge at 3000 rpm for 20 minutes, and then divide into four layers, which are free oil Ⅰ, emulsion Ⅰ, protein liquid and slag. Weigh the mass of free oil I. After the protein solution is diluted, a membrane with a molecular weight cut-off of 10k is selected for ultrafiltration, and the retentate is spray-dried with an inlet temperature of 180°C and an outlet temperature of 90°C. Emulsion I was centrifuged at 7000 rpm for 20 minutes to obtain free oil II, which was weighed. The remaining emulsion phase was broken by enzymatic method, the conditions were: papain / phospholipase (2:1, w / w), temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com