Shell-like polymer oil-absorbing microsphere preparation method

A polymer and microsphere technology, applied in the field of petroleum industry, can solve the problems of complicated preparation process, unfavorable industrial enlargement and application of products, high cost, and achieve the effects of fast super lipophilicity, easy control of reaction process and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

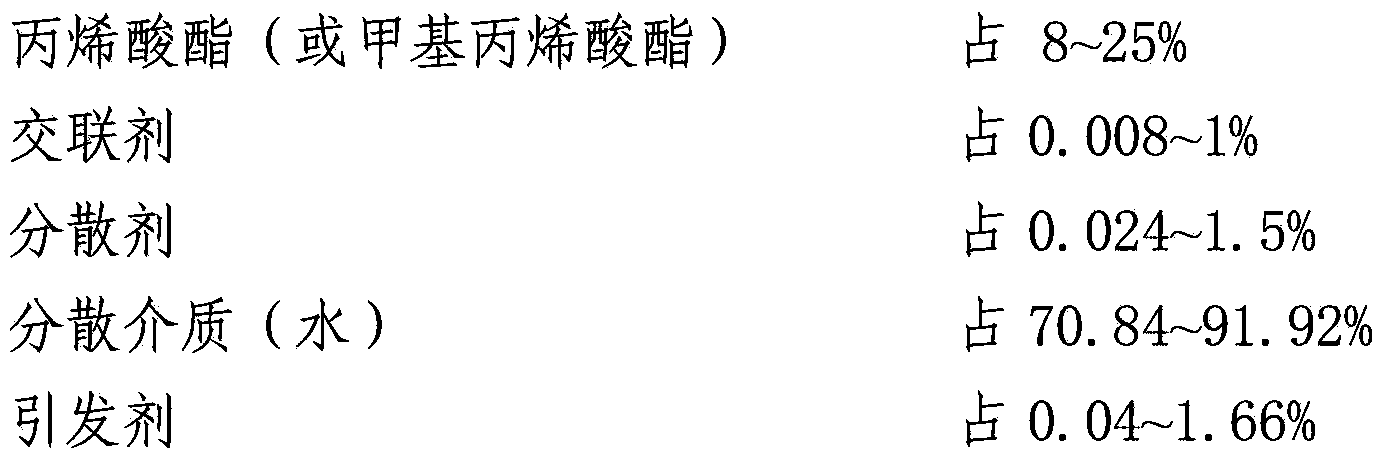

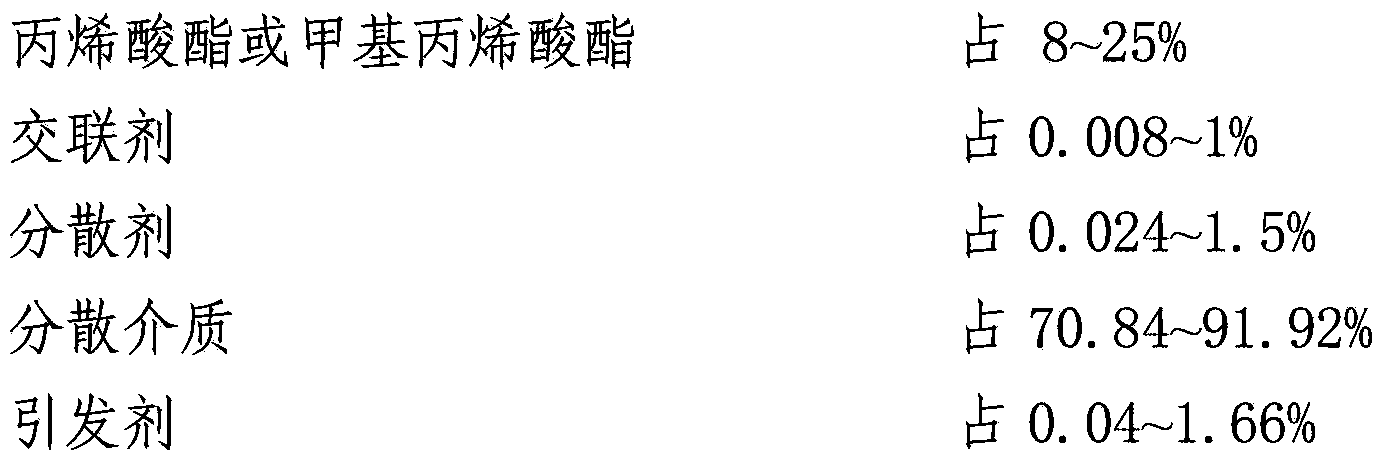

Method used

Image

Examples

Embodiment 1

[0023] Weigh 600g of deionized water and 1g of polyvinyl alcohol dispersant into a three-necked flask, heat to 45°C until the polyvinyl alcohol is completely dissolved, and sequentially add 100g of butyl methacrylate to the three-necked flask under the protection of high-purity nitrogen. 0.5g diethylene glycol diacrylate crosslinking agent, 0.6g benzoyl peroxide initiator, slowly heated to 80℃, reacted for 4 hours to obtain polymer oil-absorbing microspheres; then 1g styrene and 2g of divinylbenzene, reacted for 2 hours to form a layer of high cross-linking surface structure on the outside of the polymer oil-absorbing microspheres; then the reaction system was cooled to room temperature under stirring conditions, and finally the oil-absorbing microspheres were filtered. After washing with water, filtering with suction, and drying, shell-like polymer oil-absorbing microspheres can be obtained.

Embodiment 2

[0025] Weigh 500g of deionized water and 1g of polyvinyl alcohol dispersant into the three-necked flask, heat to 45°C until the polyvinyl alcohol is completely dissolved, under the protection of high-purity nitrogen, sequentially add 100g of butyl methacrylate, 3g 1,6-hexanediol diacrylate crosslinking agent, 3g benzoyl peroxide initiator, slowly heated to 80°C, reacted for 4 hours to obtain polymer oil-absorbing microspheres; then 1g styrene and 5g of divinylbenzene, react for 2 hours to form a layer of high cross-linking surface structure on the outside of the polymer oil-absorbing microspheres; then the reaction system is cooled to room temperature under stirring conditions, and finally the oil-absorbing microspheres are filtered. After washing with water, filtering with suction, and drying, shell-like polymer oil-absorbing microspheres can be obtained.

Embodiment 3

[0027] Weigh 800g of deionized water and 2g of polyvinyl alcohol dispersant into a three-necked flask, heat to 45°C until the polyvinyl alcohol is completely dissolved, and add 100g of lauryl methacrylate to the three-necked flask under the protection of high-purity nitrogen , 0.5g 1,6-hexanediol diacrylate crosslinking agent, 0.6g benzoyl peroxide initiator, slowly increase the temperature to 80℃, react for 4 hours to obtain polymer oil-absorbing microspheres; then add 1g to the three-necked flask Styrene and 2g of divinylbenzene can react for 2 hours to form a layer of high crosslinking surface structure on the outside of the polymer oil-absorbing microspheres; then the reaction system is cooled to room temperature under stirring conditions, and finally the oil-absorbing microspheres Ball filtration, water washing, suction filtration and drying can obtain shell-like polymer oil-absorbing microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com