Kapok fiber oil absorption material

A technology of kapok fiber and oil-absorbing material, which is applied in fiber processing, plant fiber, textile and papermaking, etc., can solve the problems of slow adsorption rate and low adsorption capacity, and achieve the effects of low cost, simple processing method and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

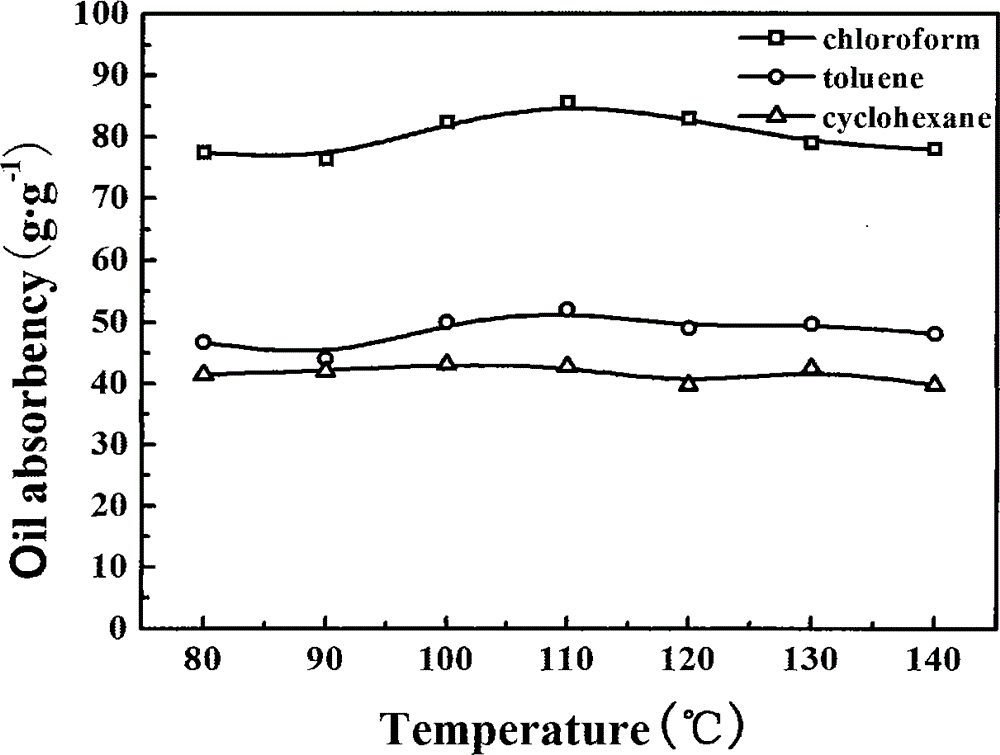

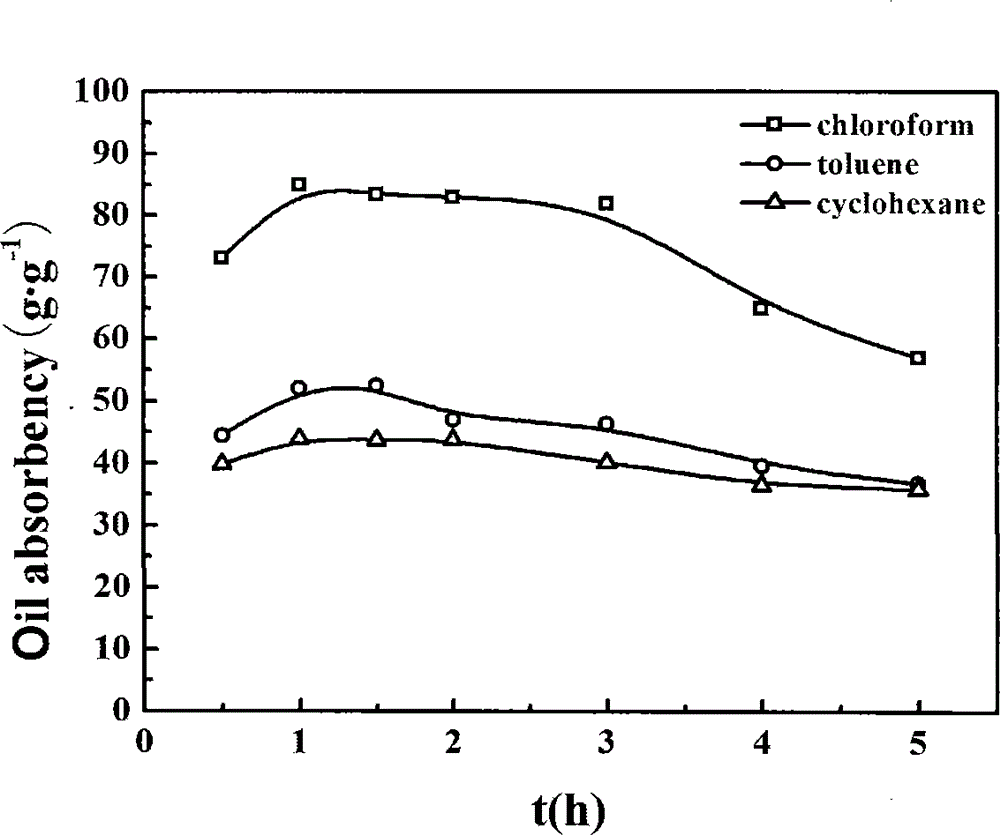

Embodiment 1

[0019] Put the original kapok fiber in the reactor, when the ratio of kapok fiber: ethanol is 1:50, add acetic anhydride with ethanol mass fraction of 15%, react at 80°C for 2h, separate the product, wash twice with ethanol, and Dry at 80°C to constant weight to get kapok fiber oil absorbent. The product in the present embodiment absorbs chloroform 75g / g, absorbs toluene 45g / g, absorbs normal hexane 42g / g.

Embodiment 2

[0021] The raw kapok fiber was placed in a reactor, treated with hydrochloric acid with a mass fraction of kapok fiber of 0.3% at 60° C. for 1 h, and then the product was isolated. Dry the isolated product and place it in a reactor. When the ratio of kapok fiber: ethanol is 1:50, add acetic anhydride with an ethanol mass fraction of 15%, react at 80°C for 2 hours, isolate the product, and wash it twice with ethanol , and dried at 80°C to constant weight to obtain kapok fiber oil-absorbing agent. The product in the present embodiment absorbs chloroform 83g / g, absorbs toluene 48g / g, absorbs normal hexane 45g / g.

Embodiment 3

[0023] Put the original kapok fiber in the reactor, when the ratio of kapok fiber: isopropanol is 1:75, add butyric anhydride with isopropanol mass fraction of 25%, react at 100°C for 1h and isolate the product, and use isopropanol Wash twice with alcohol, and dry at 80°C until constant weight to obtain kapok fiber oil-absorbing agent. The product in the present embodiment absorbs chloroform 78g / g, absorbs toluene 46g / g, absorbs normal hexane 42g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com