Preparation method of oil-absorbing material

A technology of oil-absorbing materials and monomers, applied in the field of materials, can solve the problems of slow oil absorption, few types of oil absorption, and poor oil retention, and achieve the effects of fast oil absorption, high oil absorption rate, and good oil retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

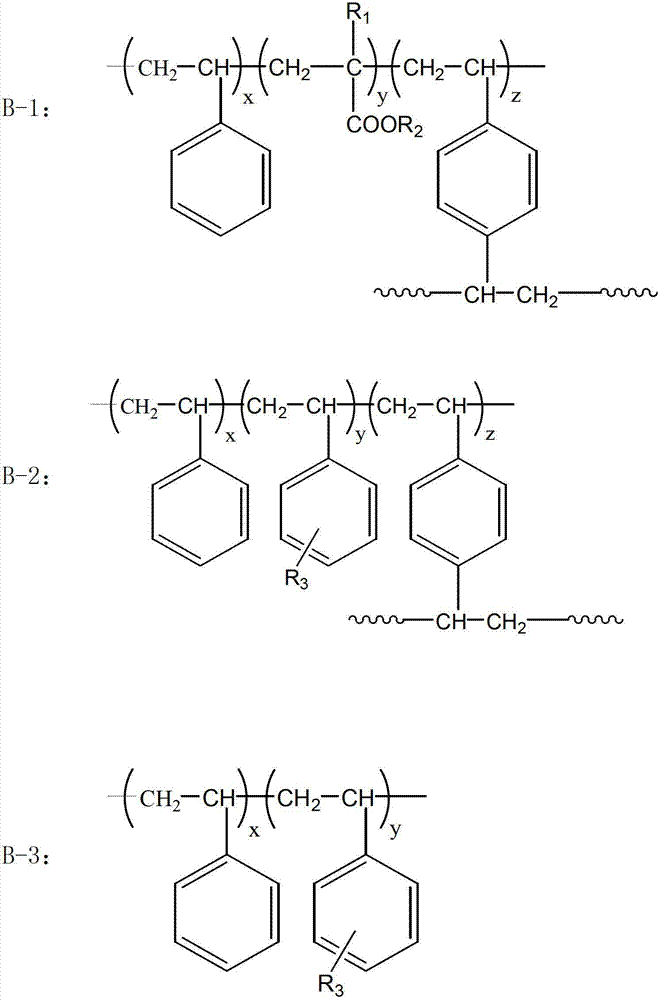

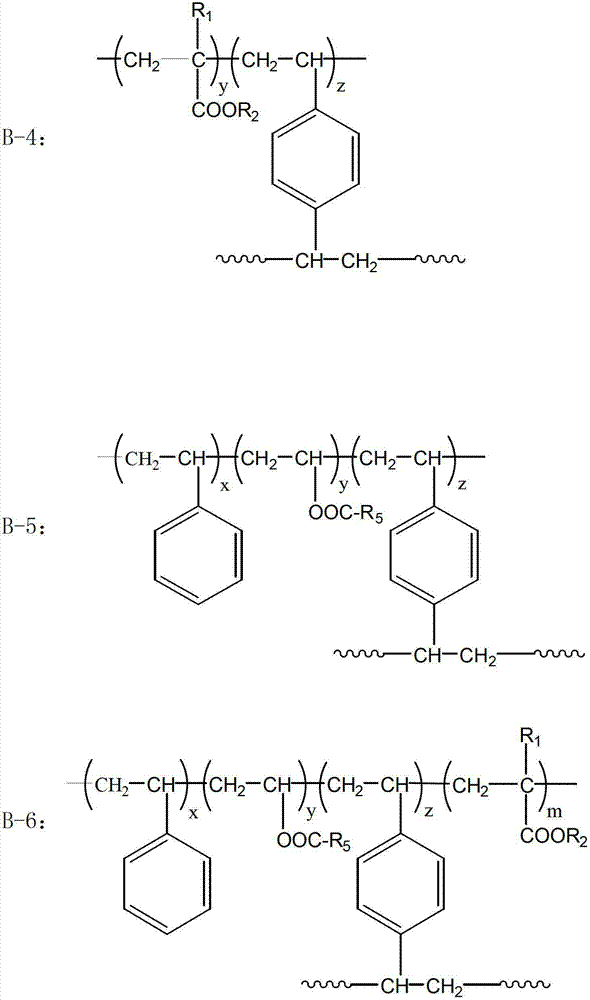

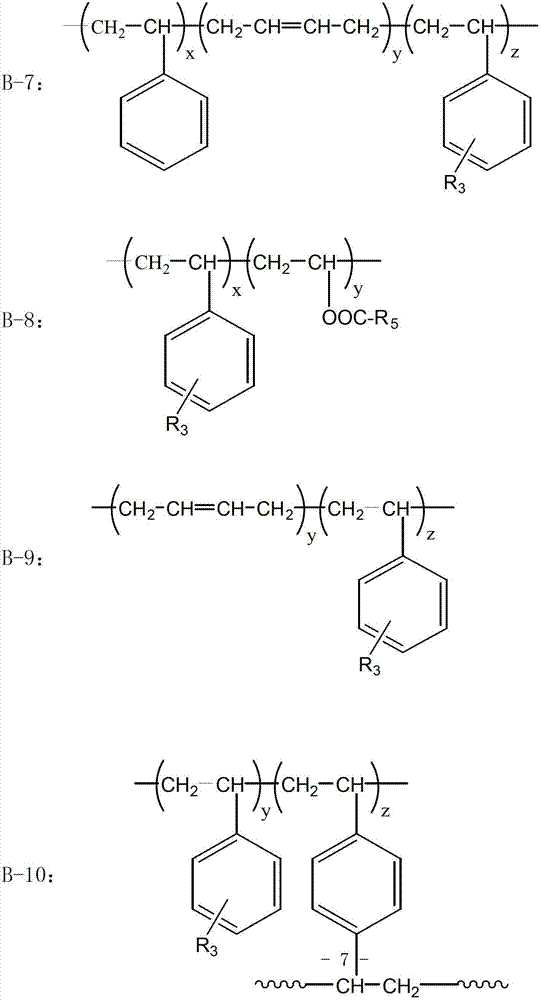

Method used

Image

Examples

Embodiment 1

[0030]Add 300 grams of styrene, 900 grams of stearyl acrylate and 20 grams of divinylbenzene into a four-liter container, then add 1900 grams of deionized water and 10.25 grams of tricalcium phosphate, mix well and heat to 55°C , When this temperature is reached, dissolve 0.021 grams of potassium persulfate in 50 grams of deionized water, add to the mixture, mix well and heat to 85 ° C, then add 2.73 grams of benzoyl peroxide, 0.989 grams of tert-amyl peroxide - 2-Ethyl acetate and 1.16 grams of dicumyl peroxide and 64 grams of styrene monomer are evenly mixed with each other, and then added to the mixed solution to react for about 6 hours. After the reaction is complete, add 1.82 grams of 3% cyclohexyl (meth)acrylate and 150 ml of water into the mixture, heat the mixture to 114°C and keep it at 114°C for about two hours, then cool the reaction mixture to 60°C. and acidified with 42.5 ml HCl. The resultant particulate polymer was then screened out with a polymer sieve, and t...

Embodiment 2

[0032] The granular polymers obtained in Example 1 were rolled by passing them through steel rollers with a gap of 0.5 mm. The granular polymer will be deformed due to extrusion between the rollers. When the granular polymer is not crushed, a large number of cracks will appear on the outer surface of the granular polymer, which will increase its oil absorption effect.

Embodiment 3

[0034] Add 280 grams of vinyl butyrate, 2000 grams of p-propyl ethylene and 20 grams of diacrylate into a four-liter container, then add 1500 grams of deionized water and 14 grams of magnesium sulfate, mix well and heat to 40 ℃, when this temperature is reached, dissolve 0.045 g of dicumyl peroxide in 70 g of deionized water, add it into the mixture, mix well and heat to 95 °C, and then add 1.05 g of tert-amyl peroxide-2-ethyl Diethyl acetate and 1.2 grams of tert-amyl peroxide-2-ethyl acetate were dissolved in 80 grams of styrene monomer, and 79 grams of liquid butane was added to the mixed reaction system, and the suspension polymerization was carried out for about 4 hours, and then The reaction mixture was cooled to 30°C. and acidified with 50 mL of HCl. Then use a polymer sieve to screen out the polymer containing low-boiling butane particles. Then, the particle polymer pellets are evaporated at a temperature of 98° C. and a vapor pressure of 0.1 Mp to obtain an oil-abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com