Self-deoiling type water surface oil stain adsorption ball

A technology for water surface oil pollution and adsorption balls, which is applied in general water supply conservation, cleaning of open water surfaces, grease/oily substances/floating matter removal devices, etc., can solve problems such as easy saturation, limited adsorption capacity of oil-absorbing plates, time-consuming and labor-intensive problems, etc. To achieve the effect of improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

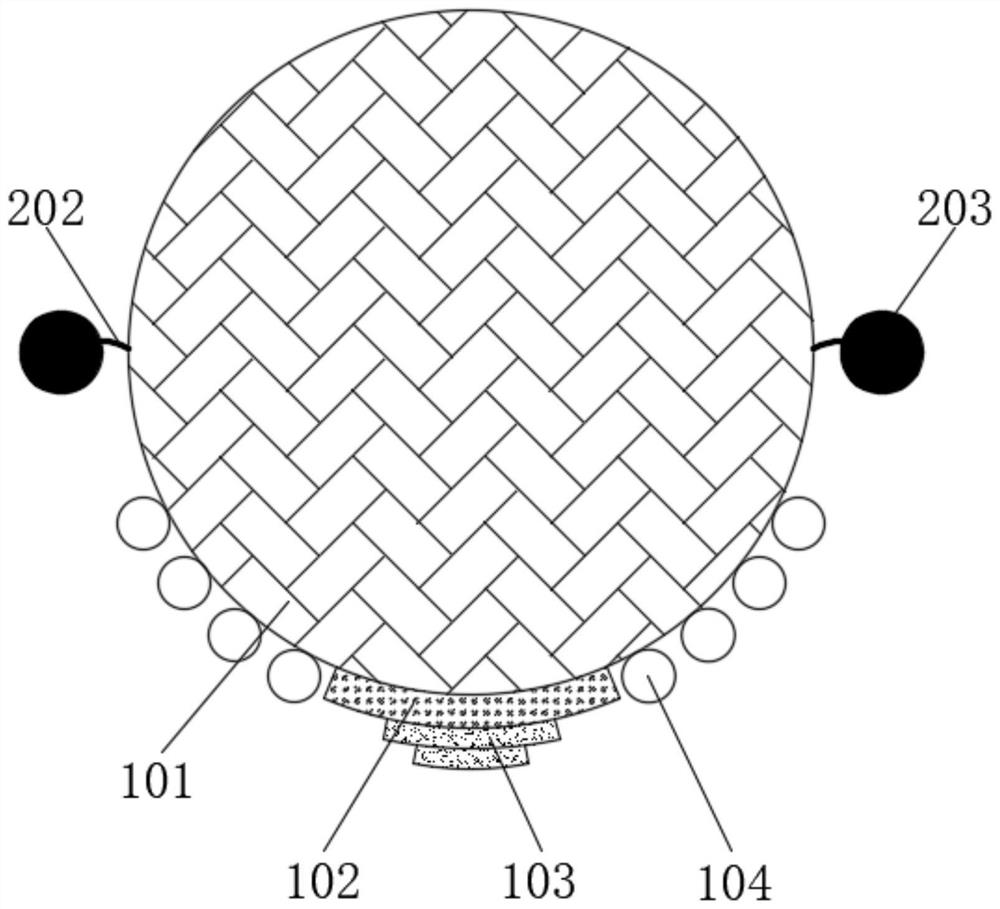

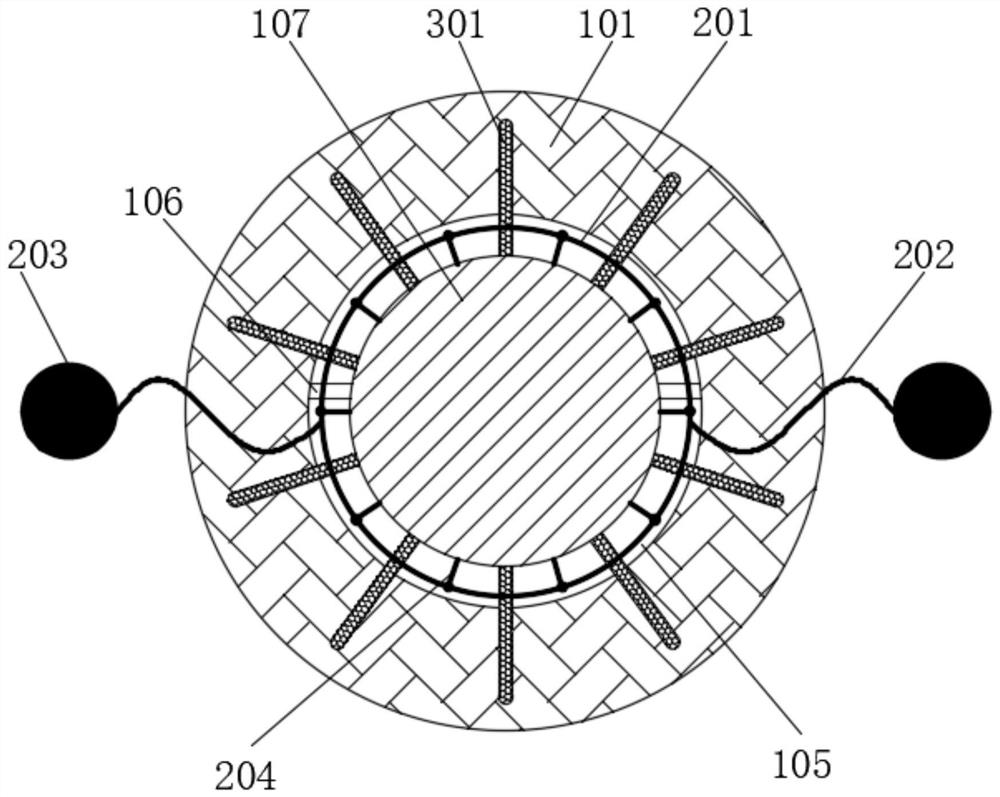

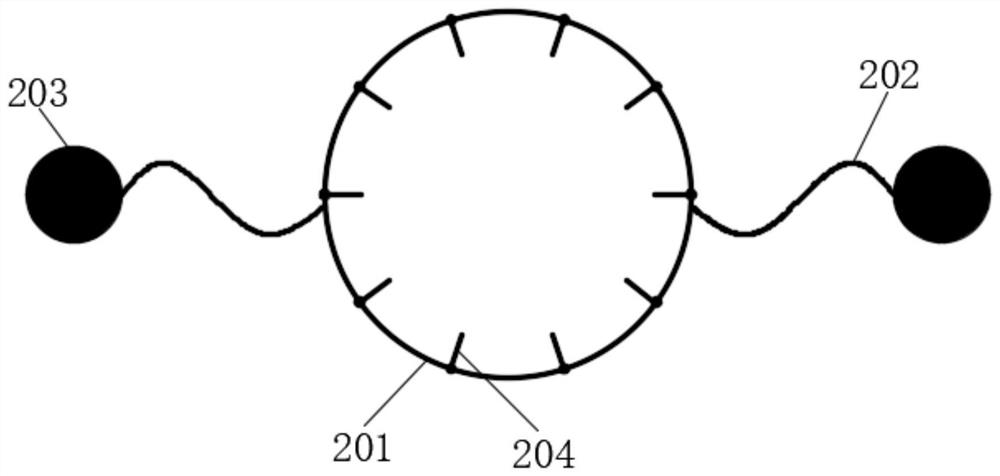

[0038] see Figure 1-3 , a self-degreasing type water surface oil dirt adsorption ball, comprising an adsorption sphere 101, the bottom end of the adsorption sphere 101 is fixedly connected with a magnet block 102, the bottom end of the magnet block 102 is connected with a plurality of counterweights 103, and the counterweights 103 The material is iron, and the counterweight 103 has four different specifications of 50g, 100g, 500g, and 1kg. The counterweight 103 is connected with the magnet block 102 under the action of magnetic attraction. The counterweight 103 is attached to the magnet block 102, which is used to change the weight of the entire adsorption ball, so that the adsorption ball can be adjusted according to the different density of the water body in the usage scene, so as to ensure that the adsorption ball can float on the water surface , improving the practicality, both sides of the magnet block 102 are provided with an inflatable floating ball 104 fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com