High salt-resistant foaming agent and preparation method thereof

A foaming agent and high-resistance technology, which is applied in the direction of chemical instruments and methods, and drilling compositions, etc., can solve the problems of foaming height, liquid-carrying capacity decline, weakening the effect of drainage and gas recovery construction technology, etc., and achieves the preparation method Simple, good resistance to high salinity, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In another specific embodiment of the present invention, a kind of preparation method of high-salt resistant foaming agent is provided, and this preparation method may comprise the following steps:

[0031] Step 1: Add starch and ethylenediaminetetraacetic acid to the high-salinity water respectively, heat to 80°C, stir at a speed of 150 rpm until the mixed solution becomes transparent and becomes viscous, and cool to obtain a mixed solution;

[0032] Step 2: adding cocamidopropyl betaine, foam booster, foam stabilizer, pH regulator and methanol to the mixed solution respectively, and stirring to obtain a high-salt-resistant foaming agent.

[0033] Specifically, in step 1, starch and ethylenediaminetetraacetic acid are successively added to the high-salinity water, heated to 70°C-85°C (preferably 80°C), and then heated at 100-200 rpm (preferably 150 rev / min) stirring at a rotating speed of 5min-10min until the mixed solution becomes transparent and becomes viscous, stop...

Embodiment 1

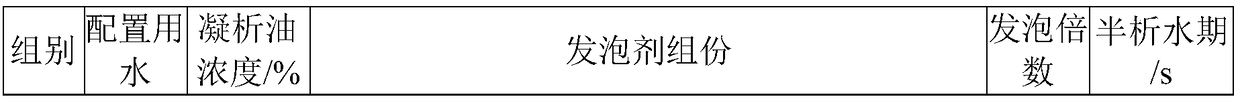

[0043] This example provides the high salinity resistance and oil resistance test evaluation tests of the high salt resistance blowing agent shown in Table 1.

[0044] Experimental Materials:

[0045] Self-prepared brine 1# (salinity 50000mg / L, Ca 2+ , Mg 2+ Total content 1000mg / L) 500mL;

[0046] Self-prepared brine 2# (salinity 100000mg / L, Ca 2+ , Mg 2+ Total content 5000mg / L) 500mL;

[0047] Self-prepared brine 3# (salinity 150000mg / L, Ca 2+ , Mg 2+ Total content 10000mg / L) 500mL;

[0048] Self-prepared brine 4# (salinity 200000mg / L, Ca 2+ , Mg 2+ Total content 15000mg / L) 500mL;

[0049] Self-prepared brine 5# (salinity 200000mg / L, Ca 2+ , Mg 2+ Total content 20000mg / L) 500mL.

[0050] A certain amount of starch, EDTA (ethylenediaminetetraacetic acid), CAB35 (cocamidopropyl betaine), foam booster (polyoxyethylene octylphenol ether-10 with a mass ratio of 3:1:1, stearin amides and tea polyphenols), foam stabilizers, pH regulators, methanol.

[0051] Condensate...

Embodiment 2

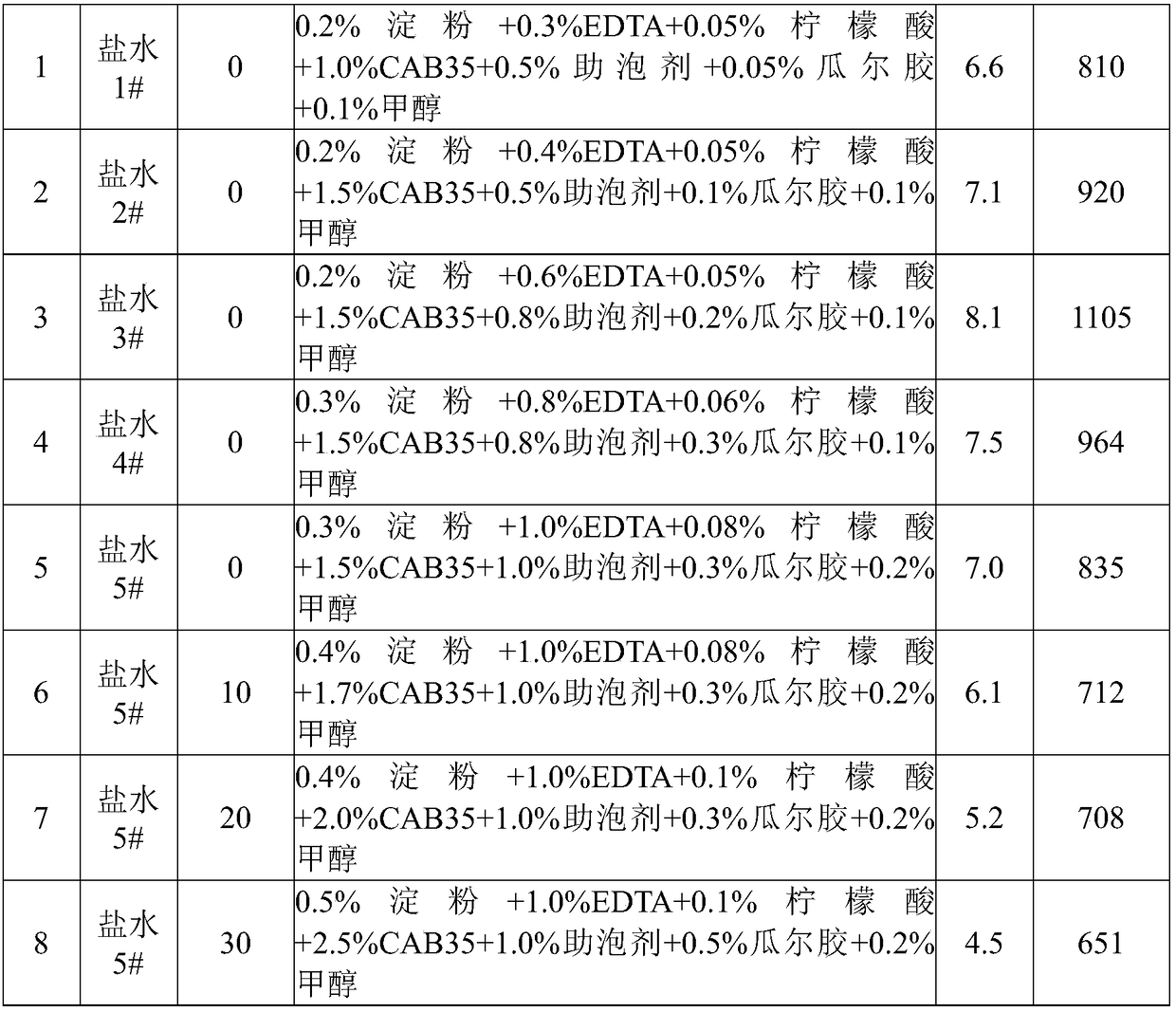

[0064] This example provides an evaluation experiment of the liquid carryover test of the high-salt-resistant blowing agent shown in Table 2.

[0065] Experimental Materials:

[0066] Self-prepared brine (salinity 200000mg / L, Ca 2+ , Mg 2+ Total content 20000mg / L) 500mL.

[0067] A certain amount of starch, EDTA (ethylenediaminetetraacetic acid), CAB35 (cocamidopropyl betaine), foam booster (polyoxyethylene octylphenol ether-10 with a mass ratio of 3:1:1, stearin amides and tea polyphenols), foam stabilizers, pH regulators, methanol.

[0068] Condensate oil 500mL.

[0069] Experimental equipment: constant temperature liquid carrying device, several 500mL beakers, 100mL measuring cylinder

[0070] experimental method:

[0071] Prepare 5 groups of foaming agents with different contents according to the order of foaming agent configuration with self-prepared salt water, each group is 100mL;

[0072] Use a graduated cylinder to take the condensate oil for later use, and mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com