Foam scrubbing agent as well as preparation method and application thereof

A foaming agent and active agent technology, applied in chemical instruments and methods, earth drilling, mining fluids, etc., can solve problems such as lack of work performance, achieve simple and easy preparation methods, good compatibility, and realize industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present embodiment provides a kind of foaming agent, by weight percentage, this foaming agent comprises:

[0025] Foaming component: betaine complex 50%;

[0026] Foam aid component: α-sodium olefin sulfonate (provided by Nanfeng Chemical Group Co., Ltd., trade name AOS) 6%;

[0027] Foam stabilizing components: coconut oil fatty acid diethanolamide 14%, fluorocarbon surfactant 10%;

[0028] and water 20%.

[0029] Among them, the above-mentioned fluorocarbon surfactant is a sulfonate-type perfluorosurfactant, that is, the product FC-15 provided by Shanghai Yingzheng Technology Co., Ltd.

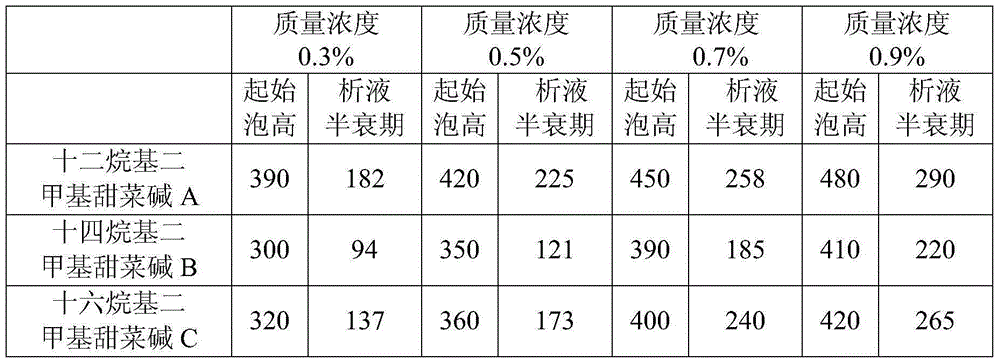

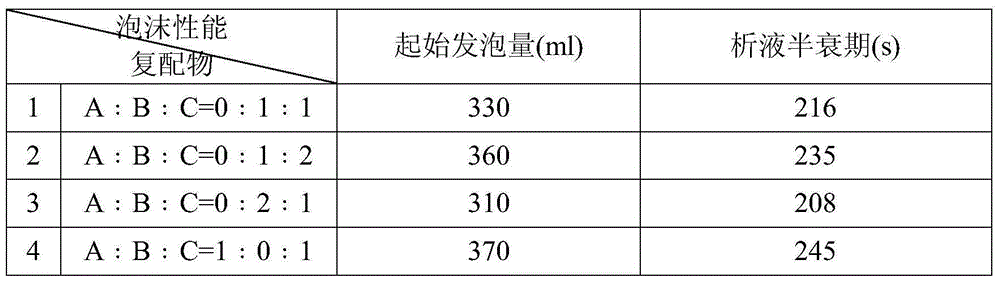

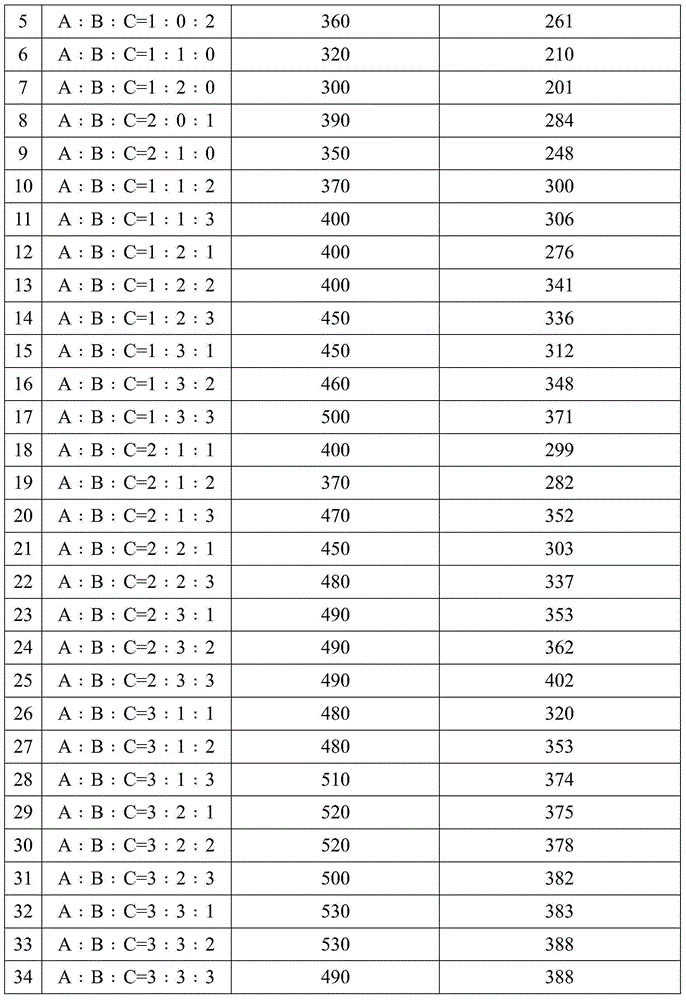

[0030] The above-mentioned beet compound is composed of three structurally similar betaine surfactants, dodecyl dimethyl betaine A, tetradecyl dimethyl betaine B and hexadecyl dimethyl betaine C. It is compounded, and the foam performance of the system obtained after compounding is better than that of any single betaine.

[0031] Proportioning and test are carried out to above...

Embodiment 2

[0051] The present embodiment provides a kind of foaming agent, by weight percentage, this foaming agent comprises:

[0052] Foaming components: betaine complex 47%;

[0053] Foam aid component: 10% of sodium α-olefin sulfonate (provided by Nanfeng Chemical Group Co., Ltd., trade name AOS);

[0054] Foam stabilizing components: coconut oil fatty acid diethanolamide 10%, fluorocarbon surfactant 13%;

[0055] and water 20%.

[0056] Among them, the above-mentioned fluorocarbon surfactant is a sulfonate-type perfluorosurfactant, that is, the product FC-15 provided by Shanghai Yingzheng Technology Co., Ltd.

[0057] Described betaine compound is according to shown in table 2, by dodecyl dimethyl betaine A, tetradecyl dimethyl betaine B, hexadecyl dimethyl betaine C according to mass ratio 3:3:2 mixed preparation.

[0058] The foam discharge agent of the present embodiment is prepared through the following steps:

[0059] Dodecyl dimethyl betaine A, tetradecyl dimethyl betaine...

Embodiment 3

[0065] The present embodiment provides a kind of foaming agent, by weight percentage, this foaming agent comprises:

[0066] Foaming components: betaine complex 43%;

[0067] Foam aid component: α-olefin sulfonate sodium (provided by Nanfeng Chemical Group Co., Ltd., trade name AOS) 12%;

[0068] Foam stabilizing components: coconut oil fatty acid diethanolamide 9%, fluorocarbon surfactant 16%;

[0069] and water 20%.

[0070] Among them, the above-mentioned fluorocarbon surfactant is a sulfonate-type perfluorosurfactant, that is, the product FC-15 provided by Shanghai Yingzheng Technology Co., Ltd.

[0071] Described betaine compound is according to shown in table 2, by dodecyl dimethyl betaine A, tetradecyl dimethyl betaine B, hexadecyl dimethyl betaine C according to mass ratio 3:3:2 mixed preparation.

[0072] The foam discharge agent of the present embodiment is prepared through the following steps:

[0073] Dodecyl dimethyl betaine A, tetradecyl dimethyl betaine B, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com