Synthetic brake shoe for urban railway vehicle and preparation method thereof

A technology for synthesizing brake shoes and urban rail vehicles, which is applied in the field of rail transit vehicle accessories, can solve the problems of brake shoe braking performance degradation, aramid pulp easy agglomeration, and mechanical performance degradation, and achieve easy control, high strength and moldability The effect of less quantity and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition (percentage by weight) of synthetic brake shoes for urban rail vehicles is as follows:

[0026] Component Weight percent

[0027] Polybismaleimide resin 12%

[0028] Nitrile Rubber 10%

[0029] Graphite 18%

[0030] Iron powder 10%

[0031] Wollastonite 8%

[0032] Friction powder 10%

[0033] Barite 30%

[0034] Coupling agent (commercially available NANDA-42) 2%

[0035] Mix the raw materials uniformly in proportion for 20 minutes, put the mixed plastic into the mold for hot pressing, and the process parameters are: temperature 220°C, pressure 40MPa, time 1.2min / mm. Finally, the molded product is put into a heat treatment furnace, and finally heat treated at 220° C. for 10 hours to obtain a product.

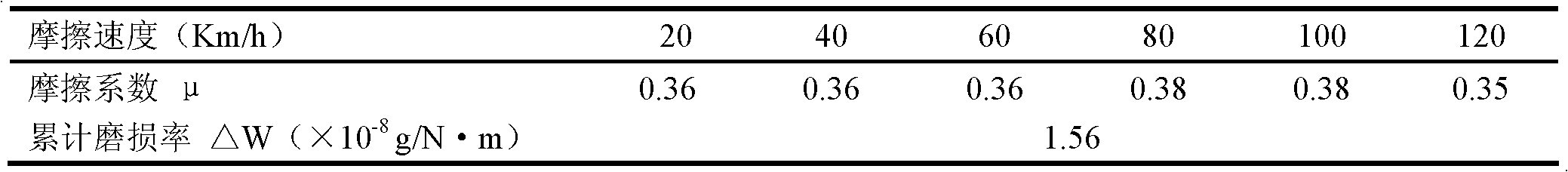

[0036] The friction and wear test was carried out on a GF150D constant speed friction machine, the friction pressure was 0.57MPa, the material of the friction disc was H13, the friction radius was 150mm, and the adjustable speed range was 0-3000r / ...

Embodiment 2

[0042] The composition (percentage by weight) of synthetic brake shoes for urban rail vehicles is as follows:

[0043] Component Weight percent

[0044] Polybismaleimide resin 14%

[0045] Nitrile Rubber 14%

[0046] Graphite 18%

[0047] Iron powder 4%

[0048] Wollastonite 8%

[0049] Friction powder 10%

[0050] Barite 30%

[0051] Coupling agent (commercially available NANDA-42) 2%

[0052] The preparation method is the same as in Example 1, wherein the process parameters of hot pressing are: temperature 220° C., pressure 40 MPa, time 1.5 min / mm. Finally, the molded product is put into a heat treatment furnace, and finally heat treated at 220° C. for 10 hours to obtain a product.

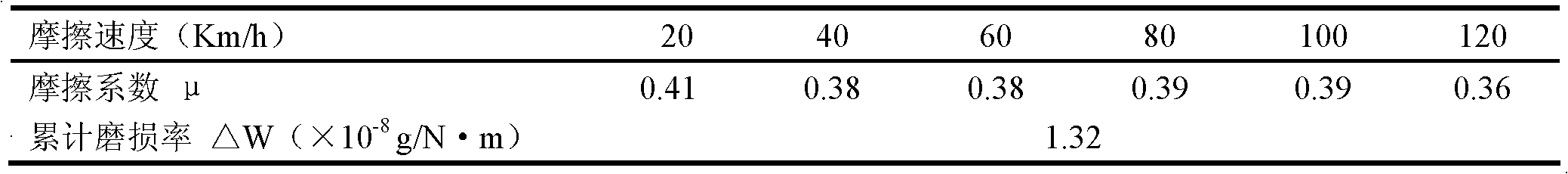

[0053] The synthetic brake shoe of urban rail vehicle that makes adopts GF150D type constant speed friction machine to test, and concrete test operation is with embodiment 1, and test result is as follows:

[0054] The friction and wear data of table 2 embodiment 2

[0055]

Embodiment 3

[0057] The composition (percentage by weight) of synthetic brake shoes for urban rail vehicles is as follows:

[0058]Component Weight percent

[0059] Polybismaleimide resin 10%

[0060] Nitrile Rubber 14%

[0061] Graphite 12%

[0062] Iron powder 7%

[0063] Wollastonite 8%

[0064] Friction powder 10%

[0065] Barite 37%

[0066] Coupling agent (commercially available NANDA-42) 2%

[0067] The preparation method is the same as in Example 1, wherein the process parameters of hot pressing are: temperature 220° C., pressure 40 MPa, time 1.5 min / mm. Finally, the molded product is put into a heat treatment furnace, and finally heat treated at 220° C. for 10 hours to obtain a product.

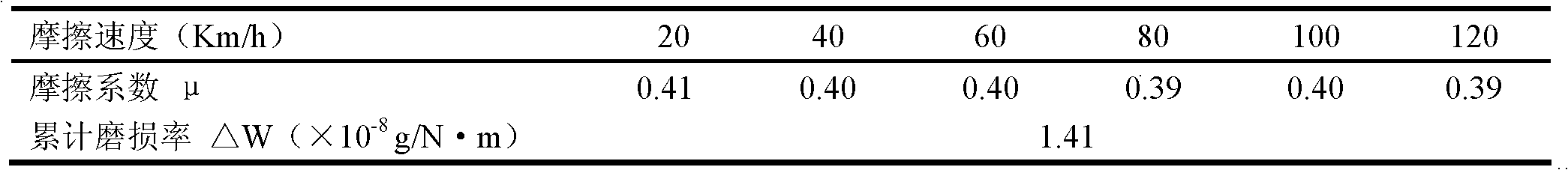

[0068] The synthetic brake shoe of urban rail vehicle that makes adopts GF150D type constant speed friction machine to test, and concrete test operation is with embodiment 1, and test result is as follows:

[0069] The friction and wear data of table 3 embodiment 3

[0070]

[0071] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com