Production of high-specific weight resin

A production method and high specific gravity technology, applied in the field of high specific gravity resin production, can solve problems such as unreasonable process, no application value, unsatisfactory performance, etc., and achieve the effect of good performance index, easy operation and good basic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is described in further detail.

[0024] Implementation Example 1

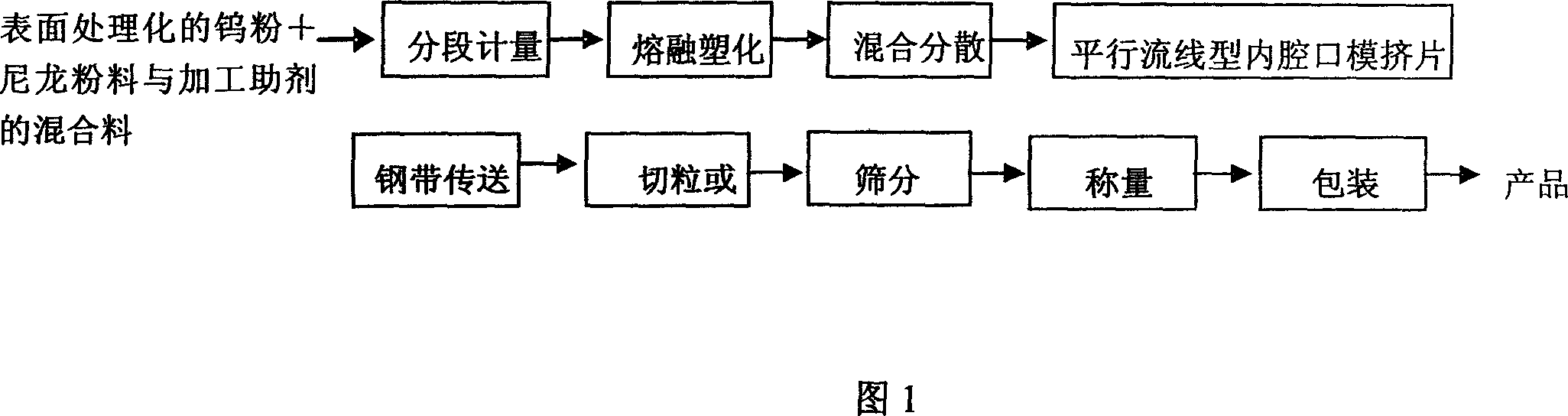

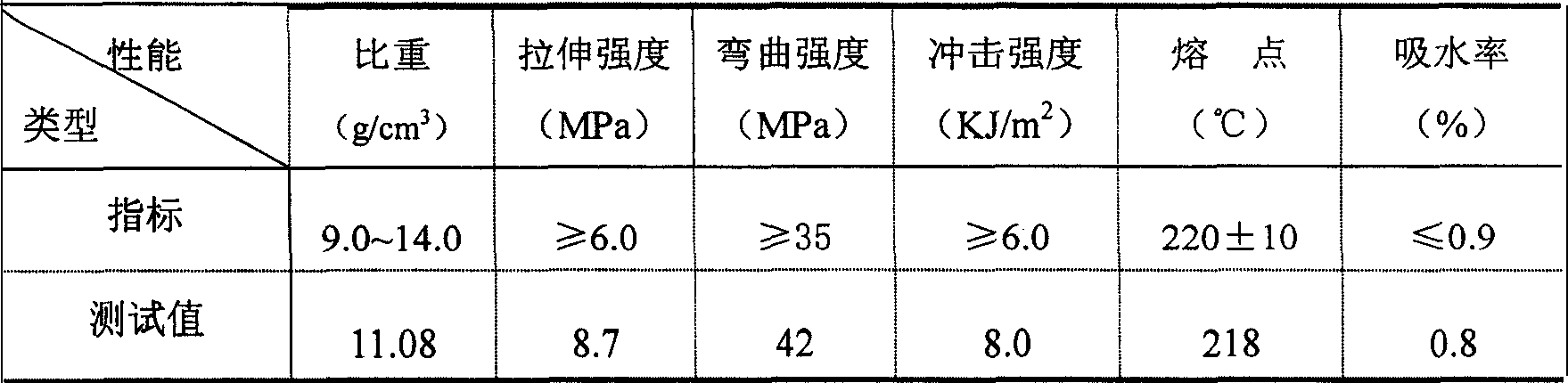

[0025] A kind of production method of high specific gravity resin is characterized in that the steps are as follows:

[0026] (1) Surface activation pretreatment of tungsten powder Mix tungsten powder and surfactant in a ball mill at room temperature in a ratio of 1000:0.8, and the specific gravity of tungsten powder is 19.1-19.5 g / cm 3 , the fineness is in the range of 200-300 mesh, and the surfactant adopts the composite active agent of the SA-HDR brand produced by Ningbo Nengzhiguang New Material Technology Co., Ltd. It adopts silane KH550: adipic acid: stearamide is 3.5- 4.5: 2.5-3.5: 2.5-3.5, and dissolve and dilute with 15-25 parts of ethanol, and their optimal ratio is 4:3:3 of silane KH550: adipic acid: stearamide, and dissolve and dilute with 20 parts of ethanol.

[0027] (2) Stir and mix at high speed, stir nylon PA powder, coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com