Surface wrinkled fiber type material and preparing method thereof

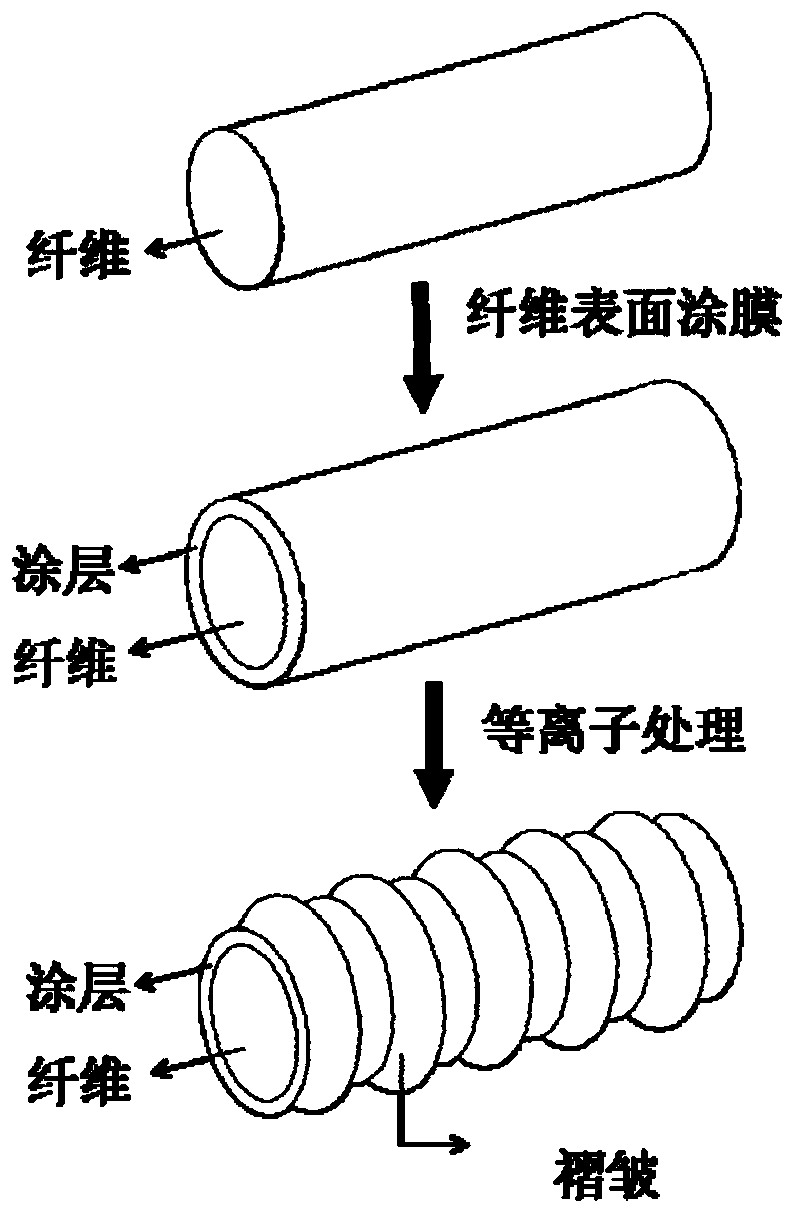

A wrinkle and fiber technology, which is applied in the preparation of micro-nano-scale patterns, surface wrinkled fiber materials and their preparation, can solve the problems of uneven ring wrinkles, inability to penetrate long fibers, roughness, etc., and achieve excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for preparing a surface wrinkled fiber fabric, comprising the steps of:

[0065] (1) Preparation of coating liquid: polydimethylsiloxane (molecular weight: 200,000) (liquid oligomer) and ethanol are stirred and mixed uniformly to prepare coating liquid, and the weight ratio of resin in the coating liquid is 0.5%;

[0066] (2) Material surface coating: make polyester fiber (solid structure, circular cross section) into polyester fabric (thickness 0.4mm), and finally soak the polyester fabric into the coating solution prepared in step (1) Then take it out and dry it to obtain a polyester fabric coated with a coating on the surface; wherein, the soaking time is 60s, and the soaking temperature is 22°C; the drying is natural drying for 30 minutes;

[0067] (3) Plasma treatment: Plasma treatment is performed on the front and back of the polyester fabric coated with a coating on the surface, and the treatment is repeated twice to obtain a wrinkled polyester fabric; ...

Embodiment 2

[0074] A method for preparing a fiber with a partially wrinkled surface, comprising the steps of:

[0075] (1) Preparation of coating liquid: Polymethyl methacrylate (molecular weight: 150,000) (liquid oligomer) and toluene are mixed uniformly to prepare coating liquid, and the weight ratio of resin in the coating liquid is 2 %;

[0076] (2) Coating film on the surface of the material: Soak the aramid fiber (solid structure, circular in cross section) into the coating liquid prepared in step (1) and then take it out and dry it to obtain the aramid fiber coated with a coating on the surface Fiber; wherein, soaking time is 50s, soaking temperature is 23°C; drying is 50°C for 10min;

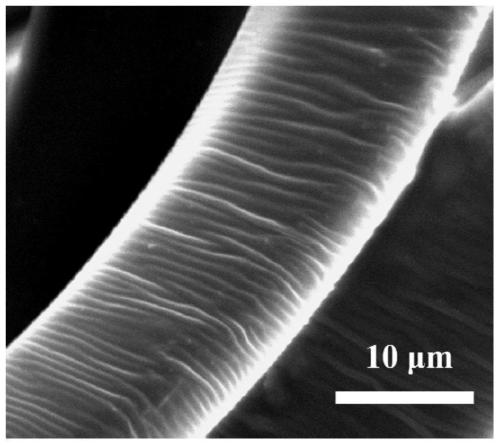

[0077] (3) Plasma treatment: the local area of the aramid fiber coated with the coating is subjected to plasma treatment (such as Figure 4 As shown), the rest of the area is covered with a metal plate, and the plasma cannot penetrate, that is, aramid fiber with a partially wrinkled surface; whe...

Embodiment 3

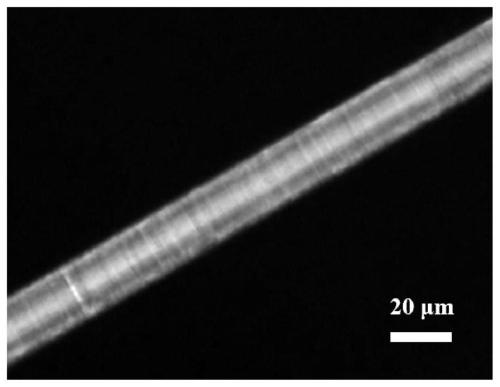

[0080] A method for preparing an optical fiber with a partially wrinkled surface, comprising the steps of:

[0081] (1) Preparation of coating liquid: Polydimethylsiloxane (molecular weight: 100,000) (liquid oligomer) and toluene are stirred and mixed uniformly to obtain a coating liquid. The weight ratio of PDMS in the coating liquid is 4.5%;

[0082] (2) Partial coating on the surface of the material: soak part of the optical fiber (skin-core structure) into the coating solution prepared in step (1) and then take it out and dry it to obtain an optical fiber with a partially coated surface. The schematic diagram is as follows Figure 5 Shown; Among them, soaking time is 55s, soaking temperature is 25°C; drying is 60°C for 7 minutes;

[0083] (3) Plasma treatment: Plasma treatment is performed on the optical fiber partially coated with a coating on the surface to obtain an optical fiber with a partially wrinkled surface; wherein, the parameters of the plasma treatment are: po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com