Low-melting-point glass glaze for sealing bottom of low-expansion ceramic liner and preparation method and application of low-melting-point glass glaze

A low-melting glass and ceramic liner technology, applied in the field of ceramics, can solve the problems affecting the service life and aesthetics of the ceramic liner, water absorption, dirt absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

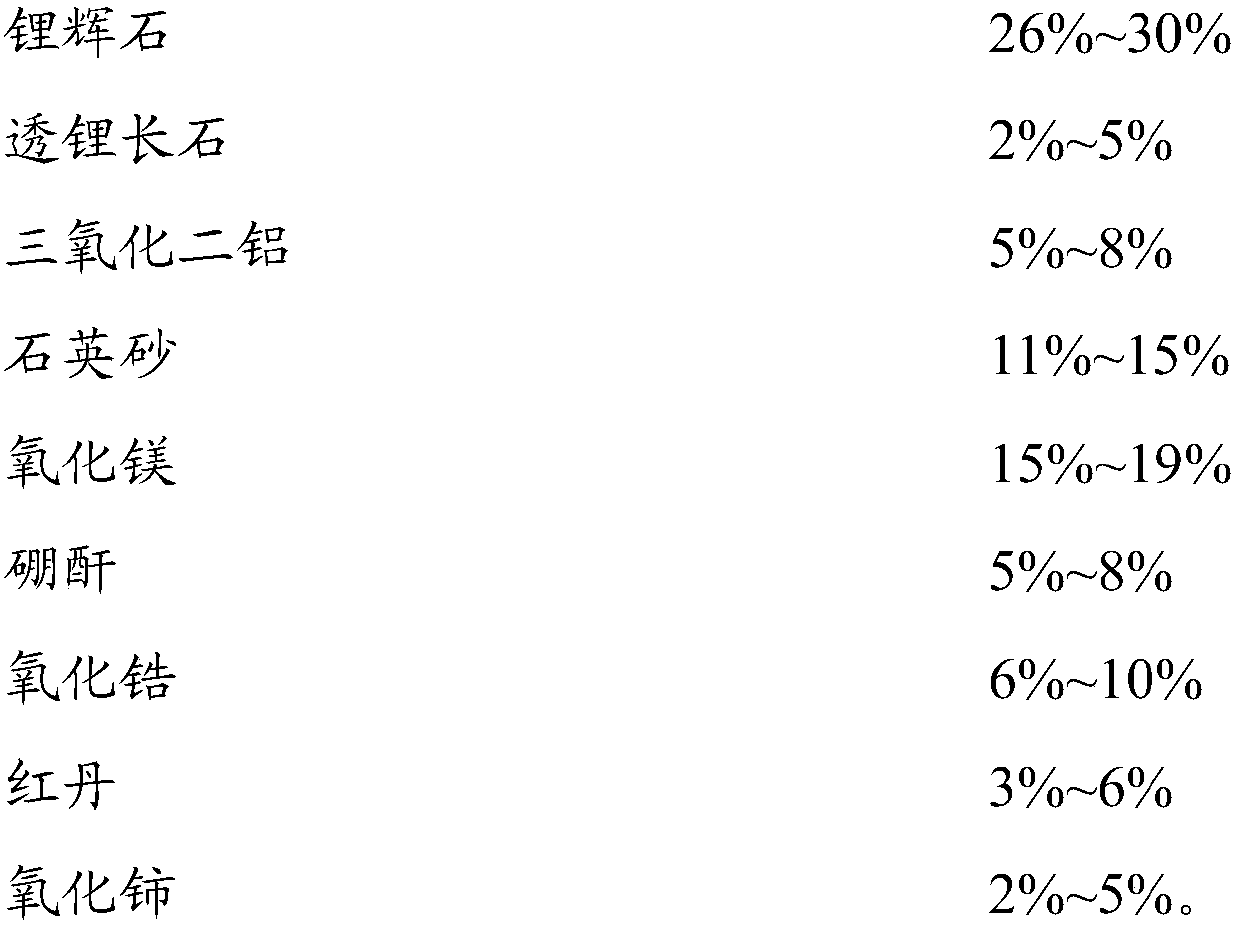

[0022] The preparation method of the low-melting-point glass glaze for the bottom sealing of the low-expansion ceramic liner according to one embodiment of the present invention includes the following S1-S3:

[0023] S1. Weigh each raw material according to the above mass percentage.

[0024] S2. After mixing the raw materials, melt them at 1420° C. to 1450° C. to form glass and then grind them into glass glaze powder.

[0025] Specifically, the raw materials are mixed and melted at a high temperature of 1420°C to 1450°C to form a molten glass, then directly poured into water and quenched into a glass frit, the glass frit is ball-milled and passed through a 200-mesh screen to obtain a glass glaze powder.

[0026] S3, making the glass glaze powder into a glaze slurry to obtain the above-mentioned low melting point glass glaze.

[0027] Specifically, glass glaze powder is mixed with water-based varnish to prepare glaze slurry to obtain the above-mentioned low-melting glass glaz...

Embodiment 1

[0033] The raw materials were weighed according to the following mass percentages: 30% of spodumene, 15% of quartz sand, 19% of magnesium oxide, 8% of boric anhydride, 6% of aluminum oxide, 5% of lithium petalite, 9% of zirconia, red Dan 3% and cerium oxide 5%. Mix the raw materials well and evenly, then melt them at a high temperature of 1435°C to form molten glass, then directly pour them into water and quench them into glass frits, ball-mill the glass frits and sieve them through a 200-mesh sieve to obtain glass glaze powder, then pour the glass Glaze powder and water-based varnish are evenly mixed to make glaze slurry to obtain low-melting glass glaze.

Embodiment 2

[0035]The raw materials were weighed according to the following mass percentages: 29% of spodumene, 15% of quartz sand, 17% of magnesium oxide, 7% of boric anhydride, 8% of aluminum oxide, 4% of lithium petalite, 10% of zirconia, red Dan 6% and cerium oxide 4%. Mix the raw materials well and evenly, then melt them at 1420°C to form molten glass, then directly pour them into water and quench them into glass frits, ball-mill the glass frits and sieve them through a 200-mesh sieve to obtain glass glaze powder, then pour the glass Glaze powder and water-based varnish are evenly mixed to make glaze slurry to obtain low-melting glass glaze.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com