Environment-friendly coating, preparation method and application

An environmentally friendly and coating technology, applied in paper coating, coating, fiber raw material treatment, etc., can solve the problems of human health hazards, fire hazards, environmental pollution, etc., to extend the service life, improve viscosity, and enhance interaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

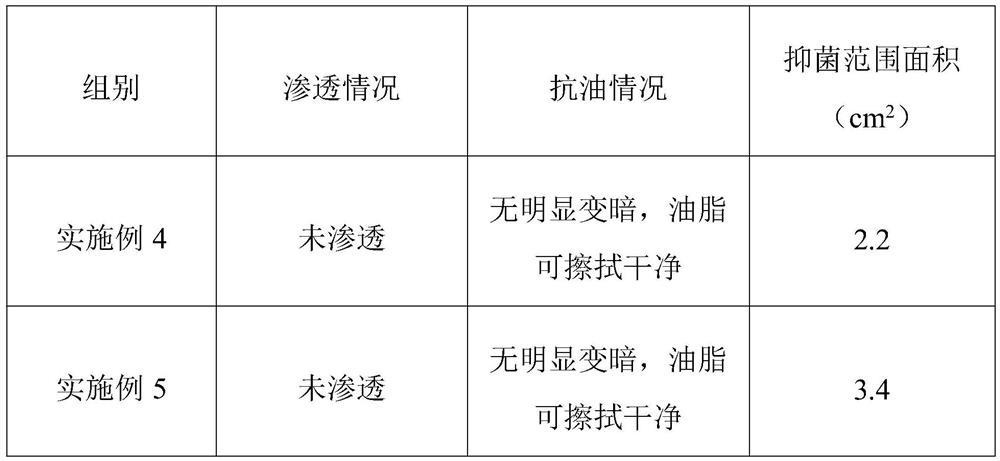

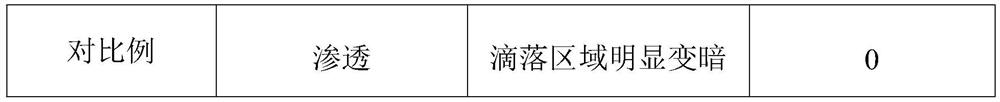

Examples

preparation example Construction

[0026] The present invention also proposes a preparation method of an environment-friendly coating, which mainly includes the following steps:

[0027] Mix potato starch with water and gelatinize at 70°C-80°C to obtain starch paste; mix dissolved polyurethane, chitosan and starch paste, then add acrylic acid and trigger in an oxygen-free environment The coating is prepared after reacting for 20h-36h under the condition of 85°C-95°C.

[0028] Specifically, potato starch is mixed with water and gelatinized under the condition of 70°C-80°C to prepare starch paste. At this time, it can help the potato starch to form a gel material with good leveling and viscosity, so as to facilitate the subsequent modification and preparation, thereby improving the mechanical strength and toughness of the coating product.

[0029] In this application, potato starch, water, and polyethylene glycol can be mixed to improve the dispersion effect of potato starch in water, avoid agglomeration, aggreg...

Embodiment 1

[0050] The purpose of this embodiment is to provide a kind of environment-friendly coating, comprise following raw material:

[0051] Potato starch 90g, polyurethane 60g, acrylic acid 30g and chitosan 20g.

[0052] The steps of the preparation method of the nanomaterial are as follows:

[0053] Potato starch and water were mixed in a mass ratio of 1:2, and gelatinized at 75°C to obtain a starch paste with a water content of 45%;

[0054] Polyurethane was dissolved in 1L of 5wt% formic acid solution to prepare polyurethane solution, and then chitosan was dissolved in 500mL of 3wt% acetic acid solution to prepare chitosan solution. And the polyurethane solution and the chitosan solution were stirred and mixed, and the stirring speed was 140rpm to obtain a mixed solution;

[0055] Mix the mixed liquid with the starch paste, and homogenize it under the condition of 0.25MPa to obtain an emulsion; then add acrylic acid and ammonium persulfate to the emulsion in turn, stir when add...

Embodiment 2

[0057] The purpose of this embodiment is to provide a kind of environment-friendly coating, comprise following raw material:

[0058] Potato starch 80g, polyurethane 50g, acrylic acid 20g, chitosan 10g and aloe vera 20g.

[0059] The steps of the preparation method of the nanomaterial are as follows:

[0060] Potato starch is mixed with water in a mass ratio of 1:1.5, and gelatinized at 70°C to obtain a starch paste with a water content of 40%;

[0061] Polyurethane was dissolved in 1L of 5wt% formic acid solution to prepare polyurethane solution, and then chitosan was dissolved in 500mL of 3wt% acetic acid solution to prepare chitosan solution. And stirring and mixing the polyurethane solution and the chitosan solution, the stirring speed is 120rpm, and the mixed solution is obtained;

[0062] Mix the mixed solution, aloe vera extract and starch paste, and homogenize under the condition of 0.2MPa to obtain an emulsion; then add acrylic acid and ammonium persulfate to the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com